Cutting head of coal rock information in transient temperature feedback of coal rock cutting and using method

A transient temperature, cutting head technology, applied in thermometers, cutting machinery, using electromagnetic means, etc., can solve the problems of cutting head fracture, increase construction cost, cutting teeth falling off, etc., so as to reduce construction cost and improve The efficiency of coal mining and the effect of speeding up the progress of the project

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

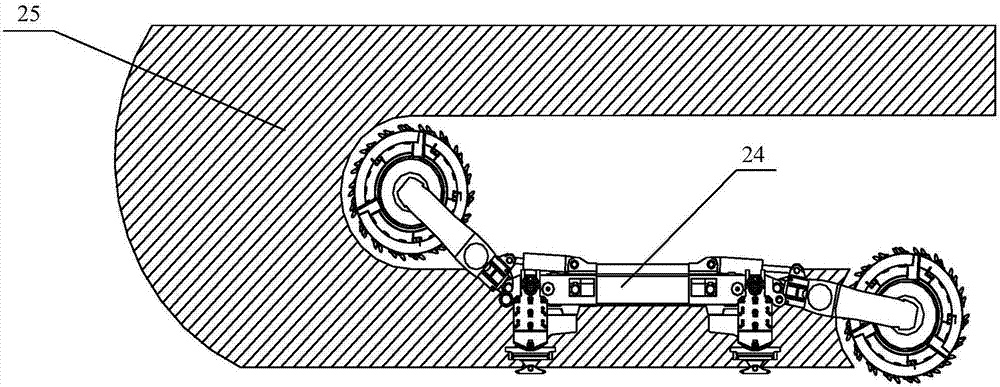

[0017] In order to solve the problems existing in the existing technology, such as Figure 1 to Figure 5 As shown, the present invention provides a cutting head for coal rock cutting transient temperature feedback coal rock information, the coal rock cutting transient temperature feedback coal rock information cutting head includes a drum 1, arranged on the drum 1 A plurality of pick assemblies 2 on the outer surface and a wireless transmitter 3 fixed in the inner cavity of the drum 1;

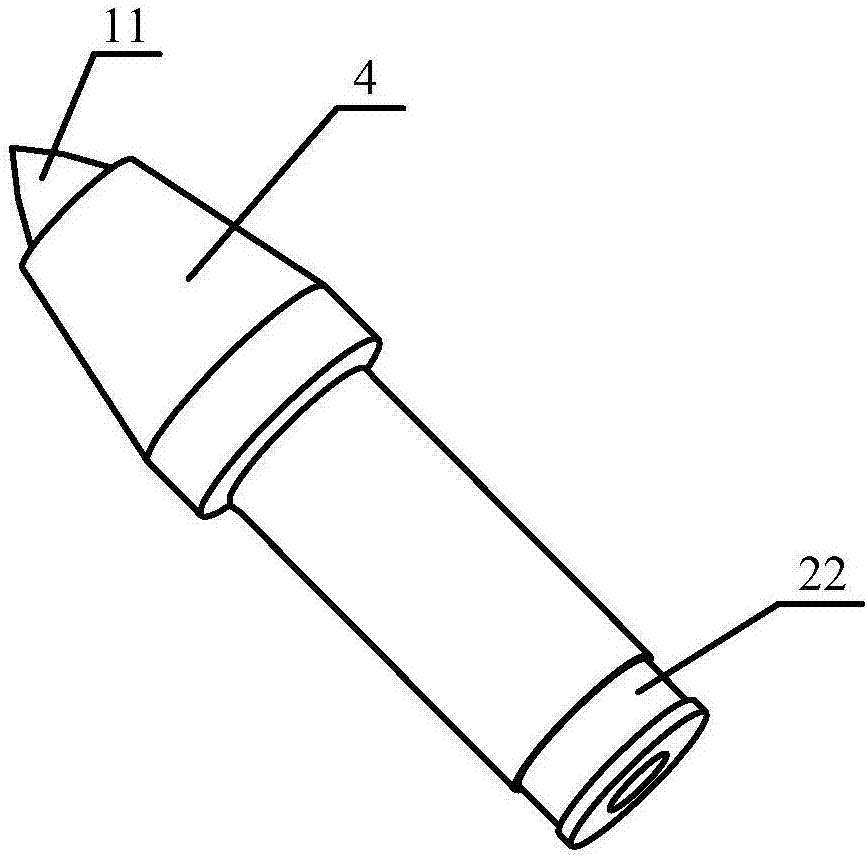

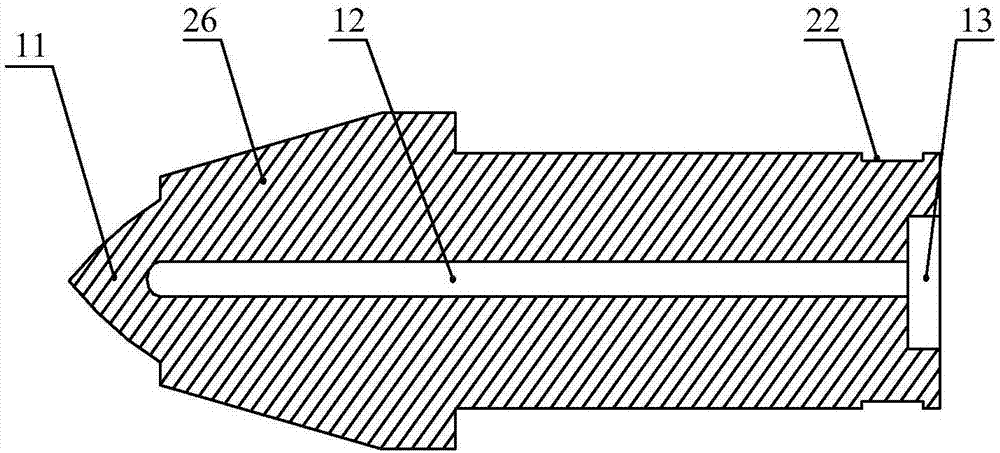

[0018] Each pick assembly 2 includes a pick 4, a tooth holder 5, a thermocouple 6, a flexible buffer sleeve 7, a threaded column 8, a nut 9, a protective box 10, a miniature voltmeter and a miniature ammeter, and the cylindrical section of the pick 4 is installed In the tooth seat 5, the front end of the tooth head 26 of the pick 4 is provided with an alloy head 11, and the pick 4 is provided with a middle hole 12 and an internal thread hole 13, and the central axis of the middle hole 12 coinc...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap