High-performance rectangular dual-channel external parallel-connection TBCC air inlet way and design method

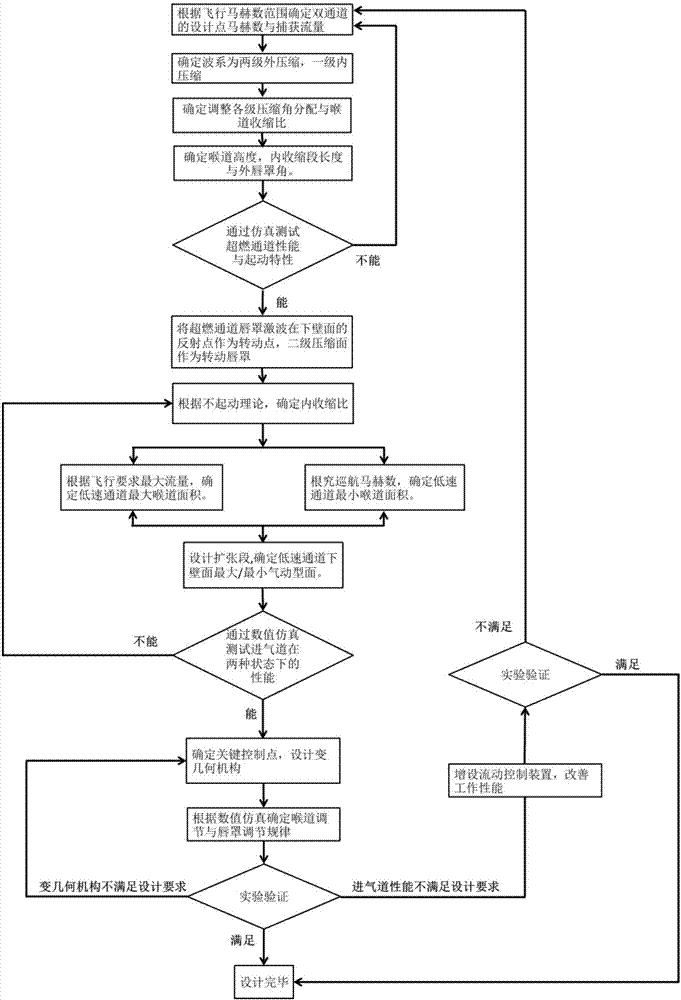

A dual-channel, high-performance technology, used in computing, mechanical equipment, jet propulsion, etc., can solve problems such as poor starting performance in low-speed channels, and achieve the effects of widening the stable working range, improving starting performance, and simplifying the structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

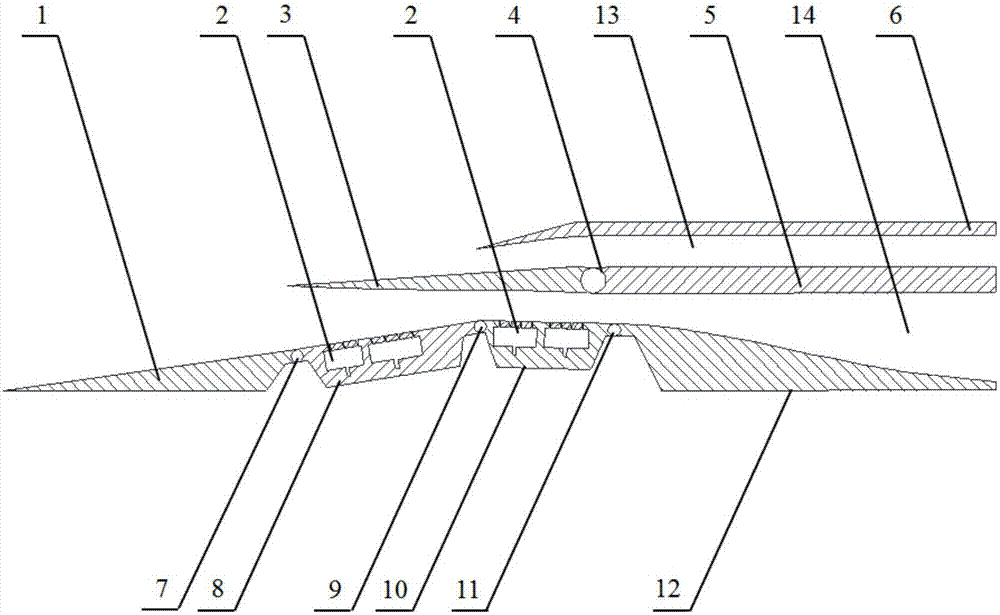

[0021] The present invention will be described in further detail below in conjunction with the accompanying drawings.

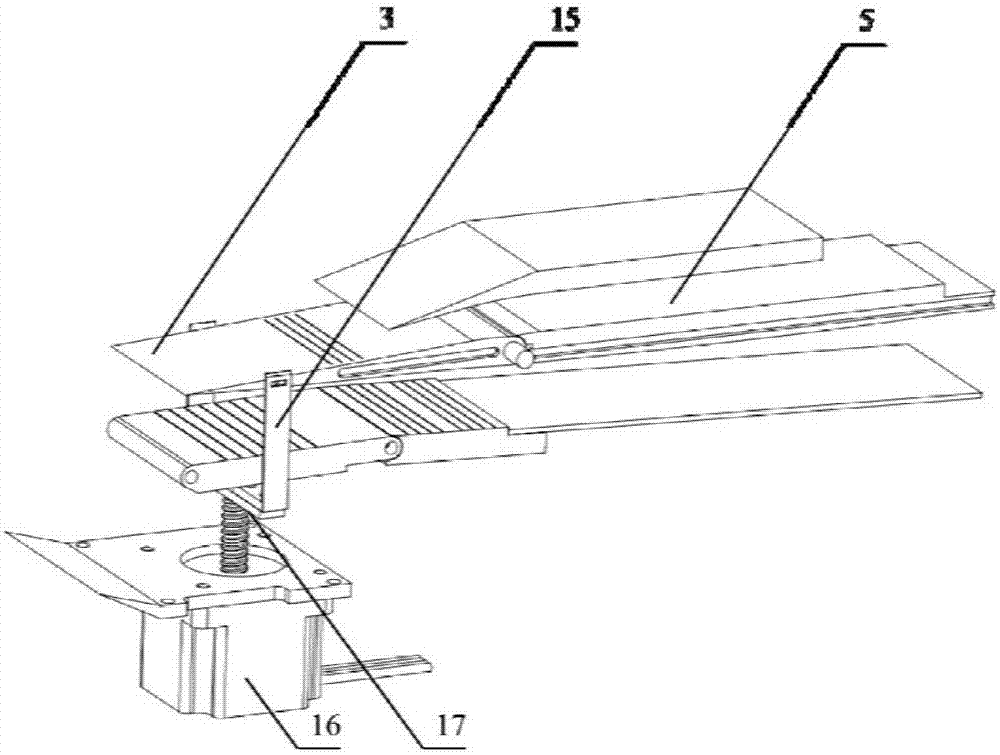

[0022] see figure 1 and figure 2 As shown, the present invention discloses a specific embodiment of a high-performance rectangular dual-channel external parallel TBCC inlet, including a high-speed channel 13 extending from front to rear, a low-speed channel 13 located inside the high-speed channel and extending from front to rear side by side with the high-speed channel Passage 14, primary compression surface 1, passage divider 5 between the high-speed passage and the low-speed passage, rotating lip cover 3 hinged at the front end of the passage divider 5 and extending forward; the outer wall of the high-speed passage 13 is the high-speed passage lip Cover 6, the inner wall surface of the low-velocity channel 14 includes a movable contraction section 8 hinged at the rear end of the primary compression surface 1, a movable throat section 10 hinged at the rea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com