An Online Energy Saving System of Two Independent Hydraulic Stations

An energy-saving system and hydraulic station technology, which is applied in the directions of fluid pressure actuation system components, fluid pressure actuation devices, mechanical equipment, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

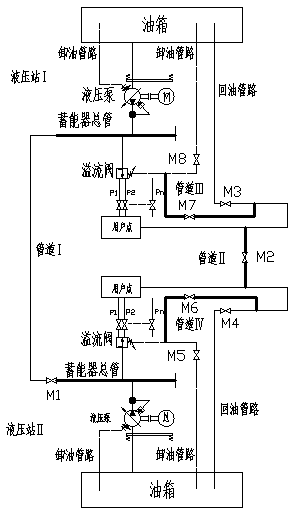

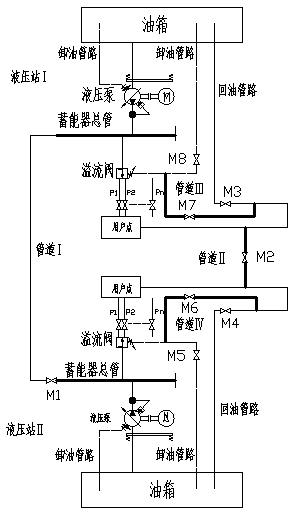

[0017] As shown in the figure, an online energy-saving system of two independent hydraulic stations, including hydraulic station Ⅰ and hydraulic station Ⅱ, there is a pipeline Ⅰ between the accumulator headers of hydraulic station Ⅰ and hydraulic station Ⅱ, and there is a valve on the pipeline Ⅰ M1; the oil return pipelines of hydraulic station Ⅰ and hydraulic station Ⅱ are connected through pipeline Ⅱ, and valve M2 is set on pipeline Ⅱ, valve M3 is set on the oil return pipeline of hydraulic station Ⅰ, and valve M4 is set on the oil return pipeline of hydraulic station Ⅱ ; There is a pipeline III between the oil return pipeline and the oil unloading pipeline of the hydraulic station Ⅰ, and a pipeline IV is installed between the oil return pipeline and the oil unloading pipeline of the hydraulic station II, the valve M7 is set on the pipeline III, and the valve M6 is set on the pipeline IV ; There is a valve M8 on the unloading pipeline of the hydraulic station Ⅰ, and a valve M...

Embodiment 2

[0024] As shown in the figure, an online energy-saving system of two independent hydraulic stations, including hydraulic station Ⅰ and hydraulic station Ⅱ, there is a pipeline Ⅰ between the accumulator headers of hydraulic station Ⅰ and hydraulic station Ⅱ, and there is a valve on the pipeline Ⅰ M1; the oil return pipelines of hydraulic station Ⅰ and hydraulic station Ⅱ are connected through pipeline Ⅱ, and valve M2 is set on pipeline Ⅱ, valve M3 is set on the oil return pipeline of hydraulic station Ⅰ, and valve M4 is set on the oil return pipeline of hydraulic station Ⅱ ; There is a pipeline III between the oil return pipeline and the oil unloading pipeline of the hydraulic station Ⅰ, and a pipeline IV is installed between the oil return pipeline and the oil unloading pipeline of the hydraulic station II, the valve M7 is set on the pipeline III, and the valve M6 is set on the pipeline IV ; There is a valve M8 on the unloading pipeline of the hydraulic station Ⅰ, and a valve M...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com