A pulverized coal swirl burner

A swirl burner and burner technology, applied in the direction of burners, burners burning powder fuel, combustion methods, etc., can solve the problems of potential safety hazards, poor combustion stability, coking of boiler water walls, etc., to improve the resistance Effects of interference ability, improvement of stable combustion performance, and reduction of combustion temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

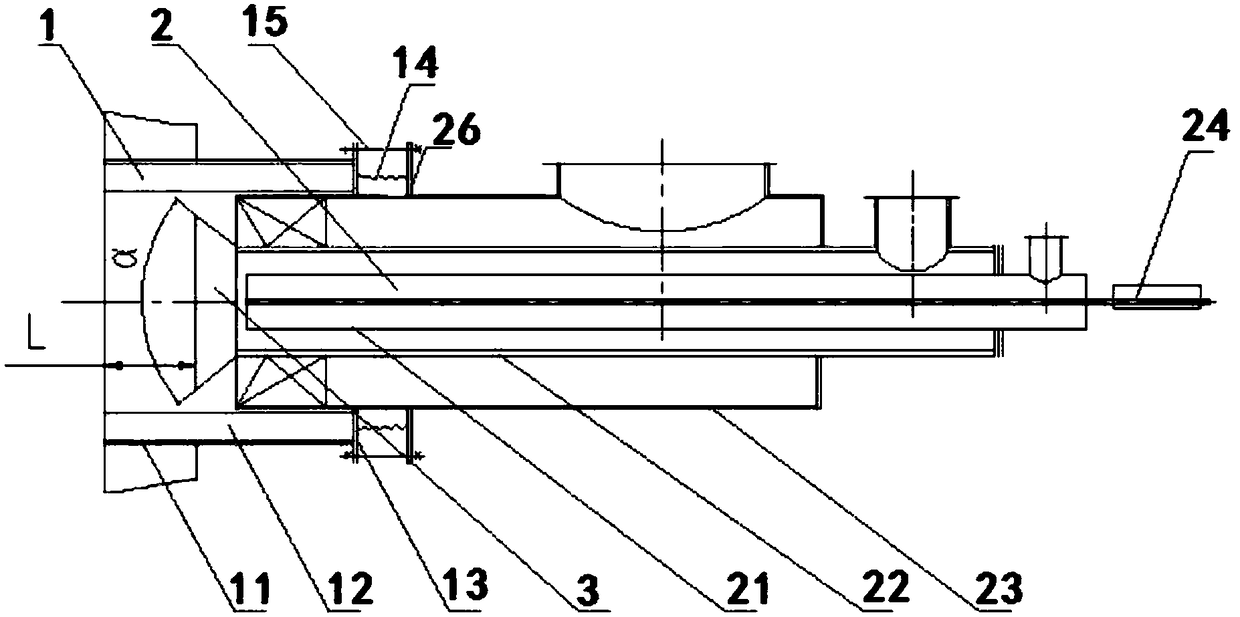

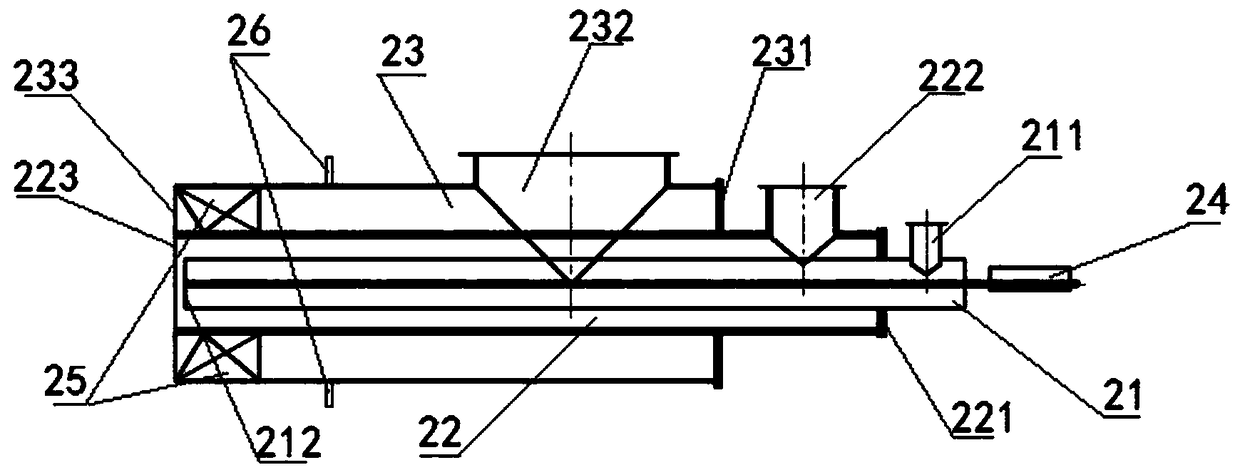

[0027] Such as figure 1 and 2 As shown, this embodiment provides a pulverized coal swirl burner, including a pre-combustion chamber 1 and a burner 2, and the burner 2 includes a central air duct 21, a primary air duct 22 and a secondary air duct 23, and the secondary air duct The front end of 23 is a secondary air outlet 233, the end of the secondary air pipe 23 is provided with a first sealing end cover 231, the primary air pipe 22 is sleeved inside the secondary air pipe 23, and the end of the primary air pipe 22 runs through the second A sealing end cover 231; the front end of the primary air duct 22 is the primary air outlet 223, the end of the primary air duct 22 is provided with a second sealing end cover 221, the central air duct 21 is sleeved inside the primary air duct 22, and the central air duct The end of the pipe 21 runs through the second sealing end cover 221; the front end of the central air pipe 21 is the central air outlet 212, and the end of the central air...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com