A rapid test system for crdm hook performance

A testing system and hook claw technology, applied in the field of CRDM hook claw performance rapid test system, can solve problems such as low demand, and achieve effective testing, effective hook claw performance, and strong pertinence.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

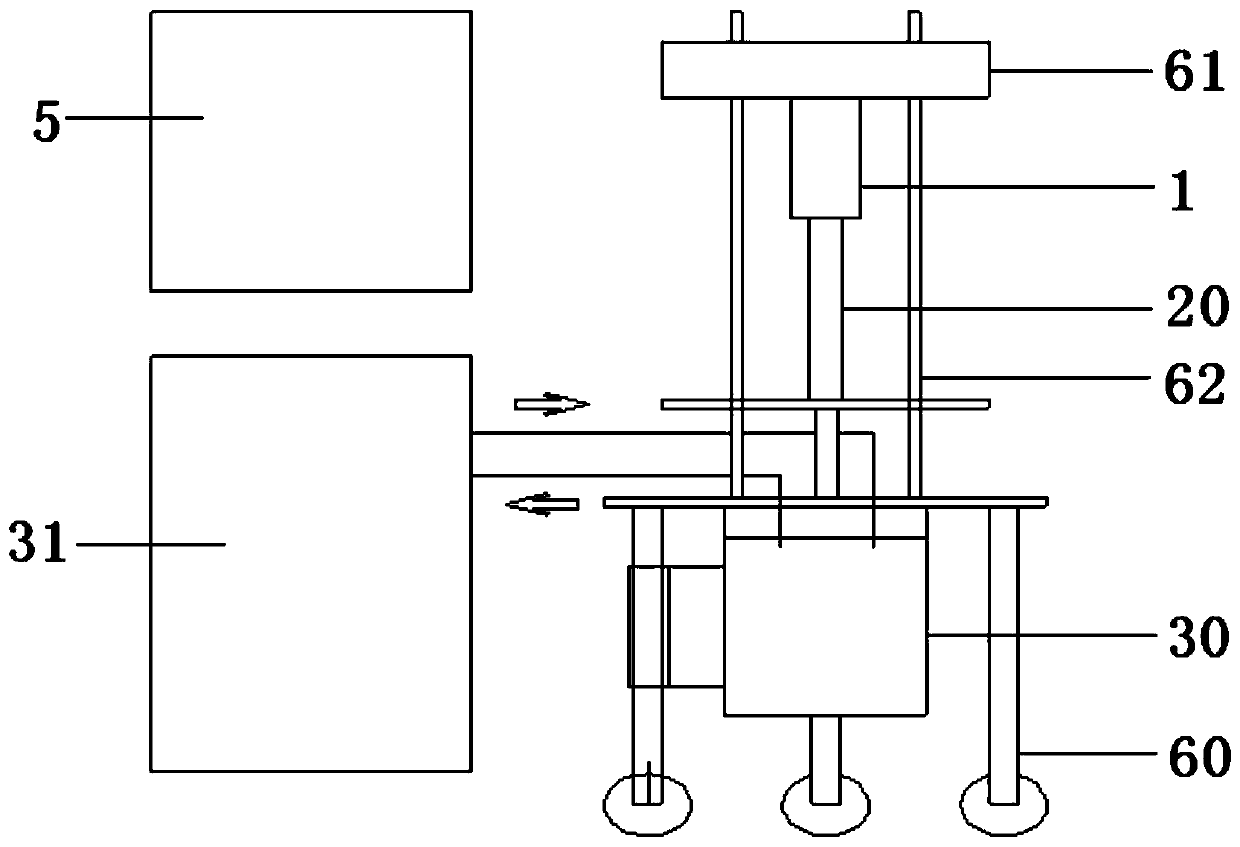

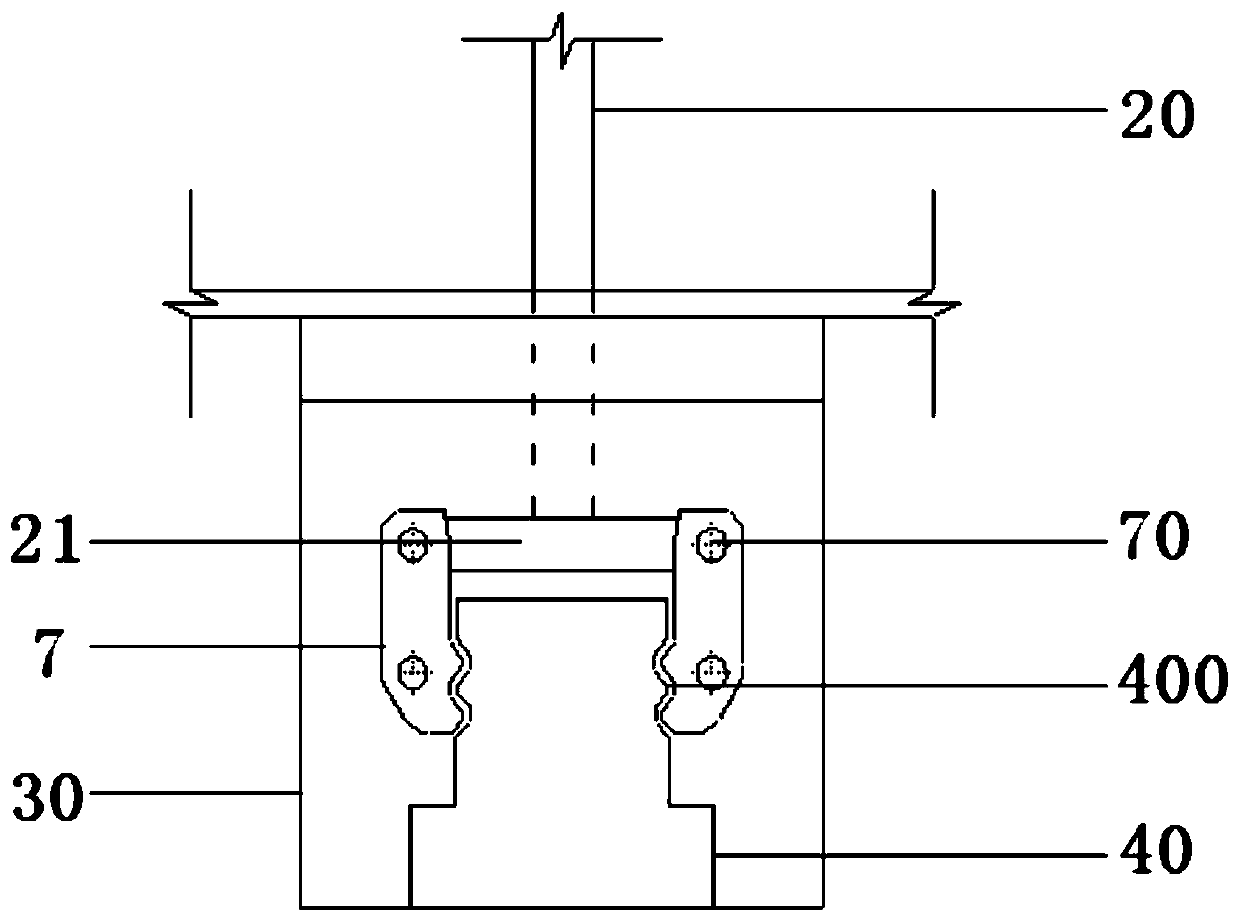

[0027] Such as figure 1 , 2 A CRDM claw performance rapid testing system shown includes a frame assembly, an operation unit and a control unit 5 arranged on the frame assembly. in:

[0028] The operation unit includes a driving part 1 connected to the frame assembly, a connecting rod connected at one end to the driving part, a test kettle assembly and a simulation part. In this embodiment: the driving part 1 mainly includes a motor. The connecting rod includes a rod body 20 connected to the driving component 1 at one end, and a clamping member 21 connected to the other end of the rod body 20 . The test kettle assembly includes a kettle body 30 and a temperature and pressure regulating device 31. The required medium can be passed into the kettle body 30 as required, such as commonly used water, etc. The temperature and pressure regulating device 31 can adjust the temperature and pressure of the medium, thereby Simulate the working environment of the claw in the primary circ...

Embodiment 2

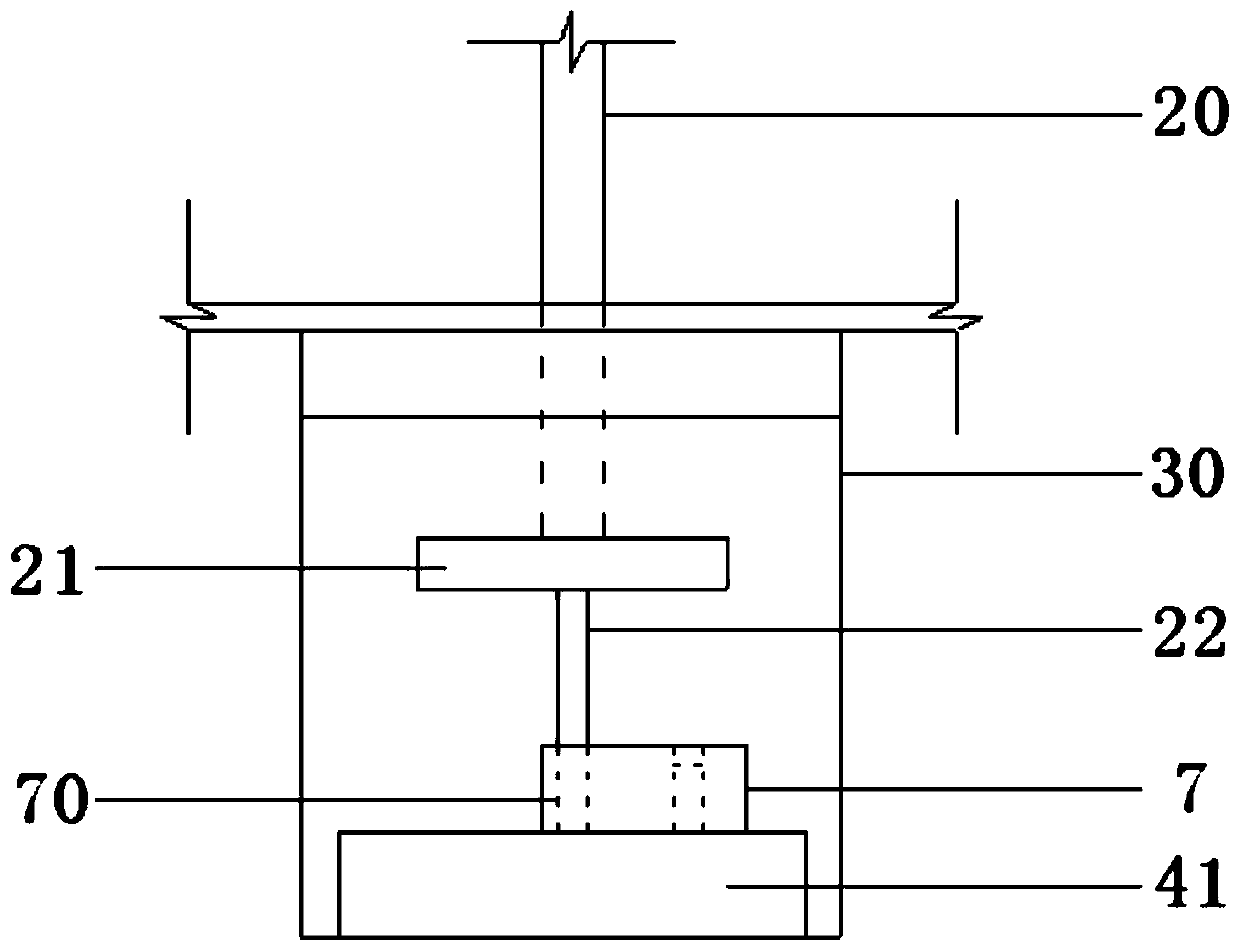

[0034] Such as figure 1 , 3 A CRDM claw performance rapid testing system shown includes a frame assembly, an operation unit and a control unit 5 arranged on the frame assembly. in:

[0035] The operation unit includes a driving part 1 connected to the frame assembly, a connecting rod connected at one end to the driving part, a test kettle assembly and a simulation part. In this embodiment: the driving part 1 mainly includes a motor. The connecting rod includes a rod body 20 connected to the driving part 1 at one end, a clamping part 21 connected to the other end of the rod body 20 , and a pin simulation part 22 connected to the clamping part 21 . The test kettle assembly includes a kettle body 30 and a temperature and pressure regulating device 31. The required medium can be passed into the kettle body 30 as required, such as commonly used water, etc. The temperature and pressure regulating device 31 can adjust the temperature and pressure of the medium, thereby Simulate t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com