High speed wrapping machine head

A wrapping and head technology, applied in the field of high-speed wrapping heads, can solve the problems of small operating space, insufficient fineness, unsatisfactory stability, etc., and achieve the effect of small space resistance, fixed and stable extraction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

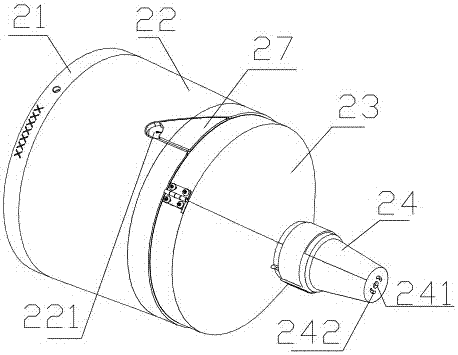

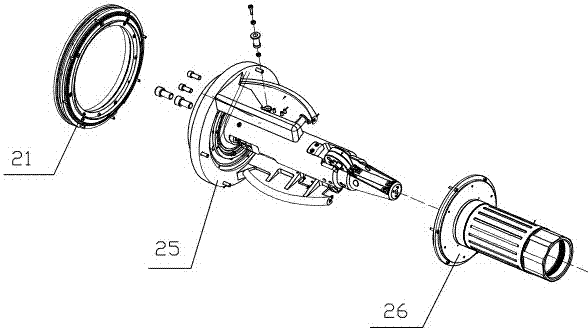

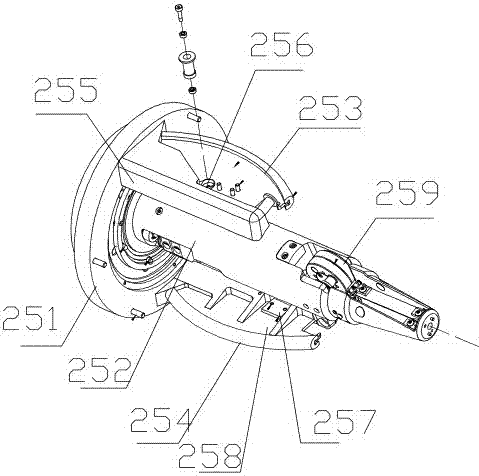

[0038] Example 1, such as figure 1 and figure 2 As shown, a high-speed wrapping machine head includes a machine shaft, a base seat 21 that rotates with the machine shaft as an axis, and a driving device that drives the machine shaft to rotate. The housing is connected with the base plate base 21 and the main passage for the main line to pass through; it also includes a main stabilizer 25 connected to the base base base 21 and rotating with the base base base 21 and a belt winding member 26 connected with the base base base 21 and rotating with the base base base 21, The bag is wound around the belt wrapping member 26 .

[0039]The driving device can use conventional driving components such as motors to drive the machine shaft to rotate, thereby driving the base plate base 21 to rotate around its own axis. A main channel is provided at the center of the base plate seat 21 and the housing, and the main line passes through the main channel. The wrapping tape is installed on t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com