Safe disconnecting device for MOV module temperature alloy

A technology for separating devices and modules, applied in emergency protection devices, electrical components, circuits, etc., can solve the problems of inaccurate and sensitive MOV chip process, long temperature transfer process, large temperature loss, etc., to facilitate mechanized production, avoid Heat-damaged, low-cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The embodiment of the present invention will be explained in detail below in conjunction with the accompanying drawings. The examples given are only for the purpose of illustration, and cannot be interpreted as limiting the present invention. The accompanying drawings are only for reference and description, and do not constitute the scope of patent protection of the present invention. limitations, since many changes may be made in the invention without departing from the spirit and scope of the invention.

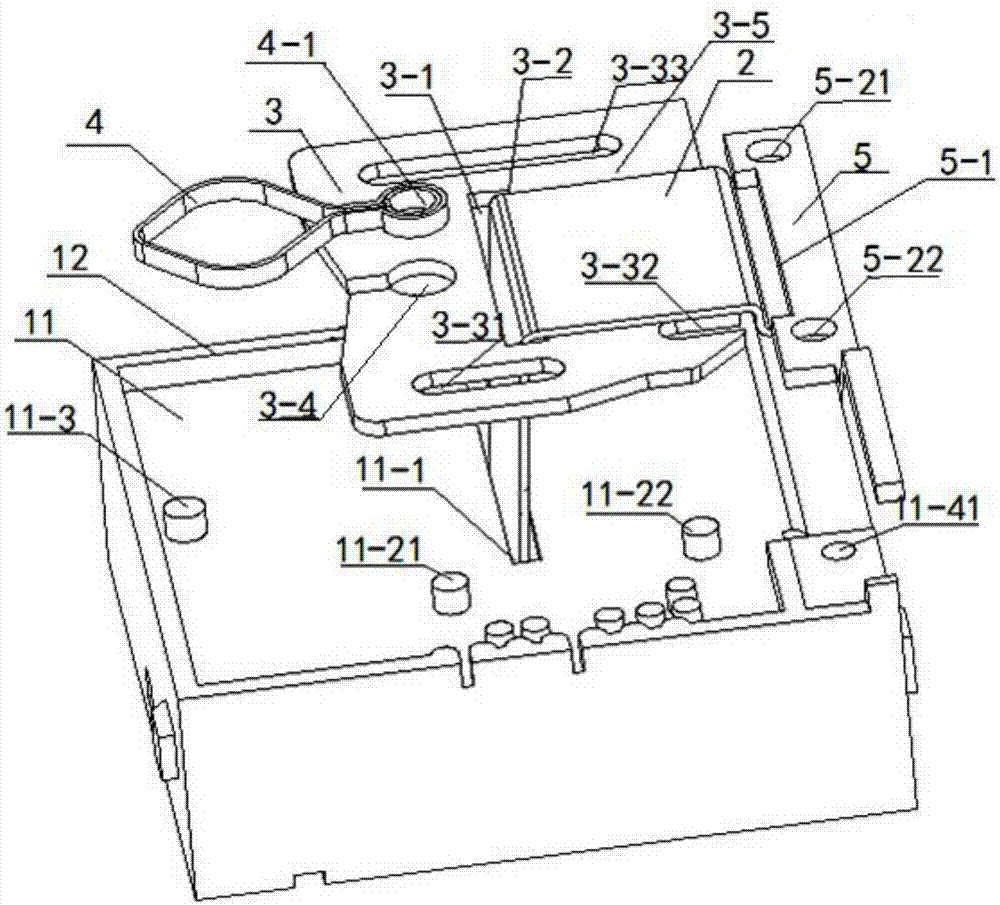

[0023] A structural explosion diagram of a safety release device for a MOV module temperature alloy provided in an embodiment of the present invention, as shown in figure 1 As shown, in this embodiment, a safety release device for MOV module temperature alloy is provided with the MOV module, and the MOV module includes MOV chip A (shaded, not shown in the figure), release Cavity 1, temperature alloy sheet 2, cutter 3, spring 4, MOV module lead-out electrode 5;

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Width size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com