Semiconductor laser and its temperature control method

A temperature control method and temperature control technology, which can be applied to semiconductor lasers, lasers, laser parts, etc., can solve the problems of lowering refrigeration efficiency, affecting the reliability of projection devices, and lowering optical power, and achieving the effect of preventing water vapor condensation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

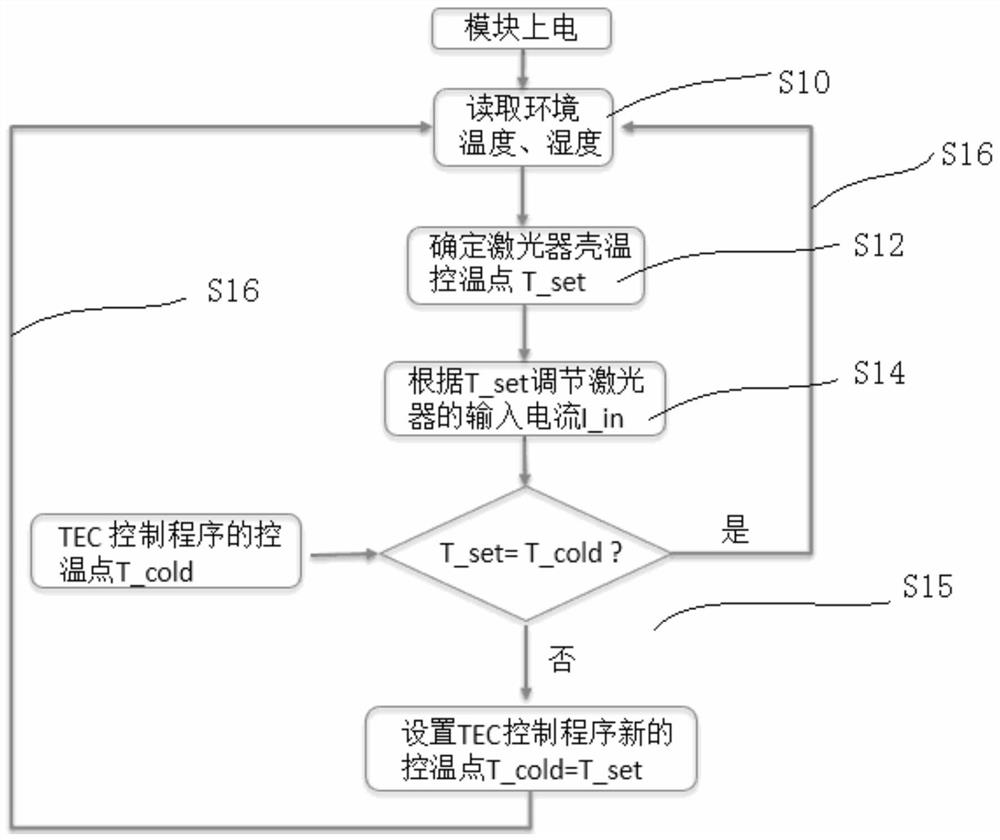

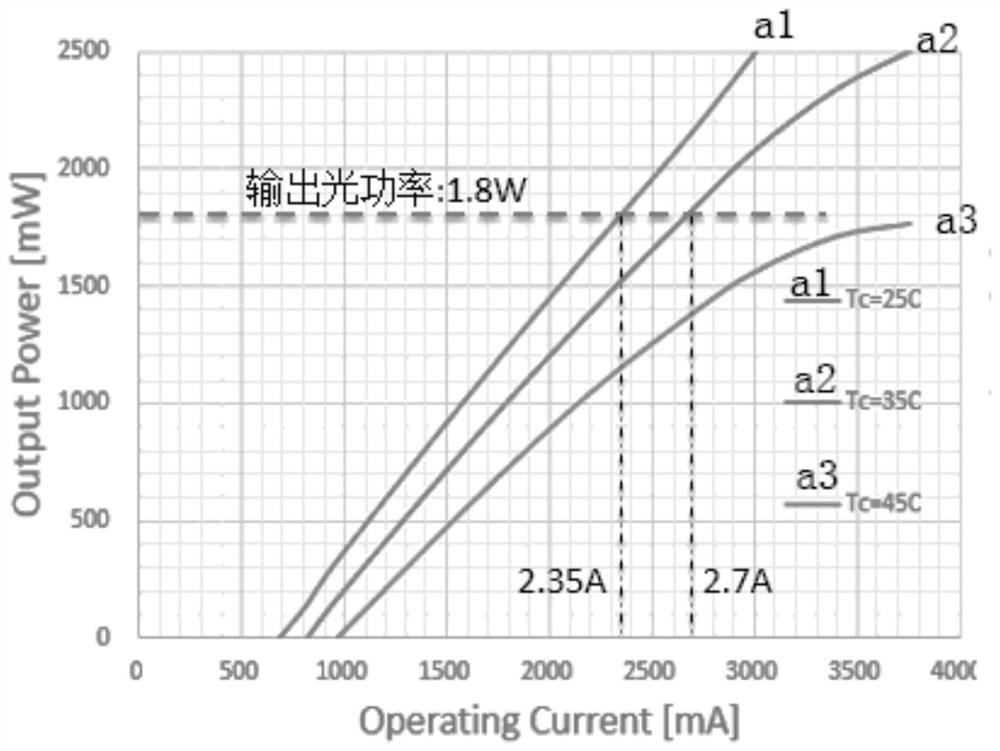

[0054] The method for controlling the temperature of a semiconductor laser provided in Embodiment 1 is based on a semiconductor laser. The semiconductor laser has an accommodating cavity, and a laser and a cooling mechanism for controlling the temperature of the laser are installed in the accommodating cavity.

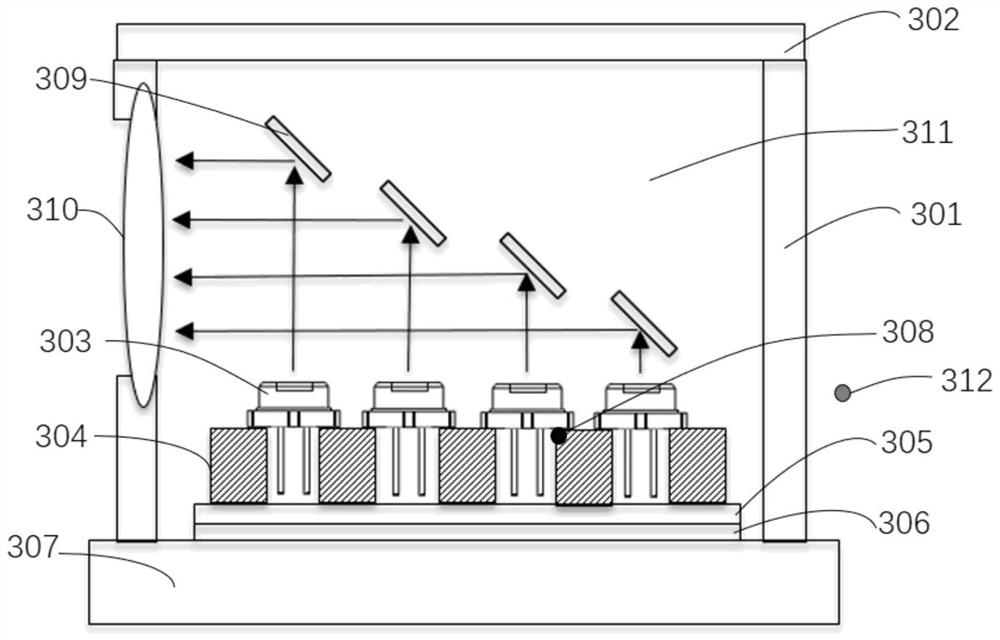

[0055] Specifically, please refer to figure 1 , figure 1 What is shown is a specific example of the above-mentioned semiconductor laser, and is not the only choice of the temperature control method shown in this embodiment.

[0056] Wherein, the red laser 303 is installed on the bottom plate 304 , and the bottom plate 304 is connected with the heat sink 307 through the heat soaking plate 305 and the cooling mechanism (TEC) 306 . The bottom plate 304 is fixed on the heat sink 307 by means of elastic connection (the fixing method is not shown in the figure), and the contact surfaces are tightly bonded by high thermal conductivity silicone grease or other low thermal re...

Embodiment 2

[0086] Please refer to Figure 5 The method for controlling the temperature of a semiconductor laser provided in Embodiment 2 is based on a semiconductor laser. The semiconductor laser has an accommodating cavity 311, and the accommodating cavity 311 is equipped with a laser 303 and a cooling mechanism 306 for controlling the temperature of the laser.

[0087] Specifically, Figure 5Shown is a specific example of the above-mentioned semiconductor laser, and its difference from the example structure of the first embodiment is that the temperature and humidity sensor 313 is defined as the second parameter detection mechanism, which is arranged in the accommodating cavity 311 and located in the laser 303 , used to collect the temperature T_air of the space around the laser 303 in the accommodating cavity 311 . In this way, as the temperature in the accommodating cavity 311 rises, the working shell temperature of the laser 303 is increased synchronously.

[0088] The temperatur...

Embodiment 3

[0109] Embodiment 3 provides another temperature control method of a semiconductor laser, which adopts the combination of Embodiment 1 and Embodiment 2.

[0110] The temperature control method includes a first temperature control mode and a second temperature control mode, and the first temperature control mode and the second temperature control mode can be selectively switched.

[0111] Wherein, the first temperature control mode is the temperature control method shown in the first embodiment, and the second temperature control mode is the temperature control method shown in the second embodiment. The first temperature control mode is mainly used to determine the working shell temperature of the laser according to the temperature and humidity of the application environment. In general, the change of the temperature and humidity of the environment is relatively slow, and this method can be used normally. However, in some cases, such as when the equipment is subjected to a temp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com