Laser drive circuit

A driving circuit and laser technology, applied in lasers, laser parts, semiconductor lasers, etc., can solve the problems of lack of access and mobility, and achieve the effects of high reliability, high integration and low noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

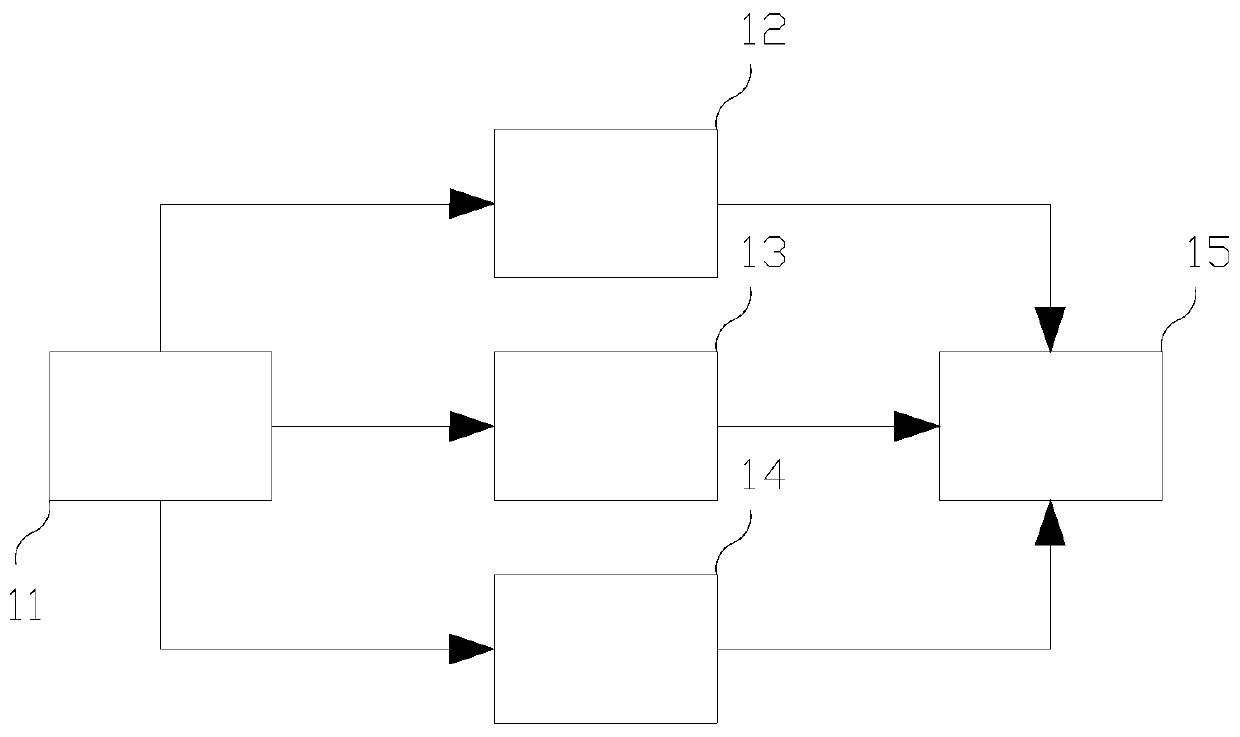

[0025] as the picture shows, figure 1 It is a circuit block diagram of the present invention, a laser drive circuit, including: a power supply circuit 11, the drive circuit is powered by a +5V single power supply circuit 11, which meets the power supply requirements of the drive circuit; wherein, the power supply circuit 11 is connected to a voltage conversion circuit 12 for The conversion from positive pressure to negative pressure also includes: a temperature control circuit 14 connected to the power circuit 11, used to control the thermoelectric cooler inside the laser according to the ambient temperature change; the power circuit 11 is also connected to an automatic power control circuit 13. The automatic power control circuit 13 is connected with the laser bias circuit 15, and is used for feedback control of the laser bias circuit 15 according to the output voltage of the monitoring detector integrated inside the laser.

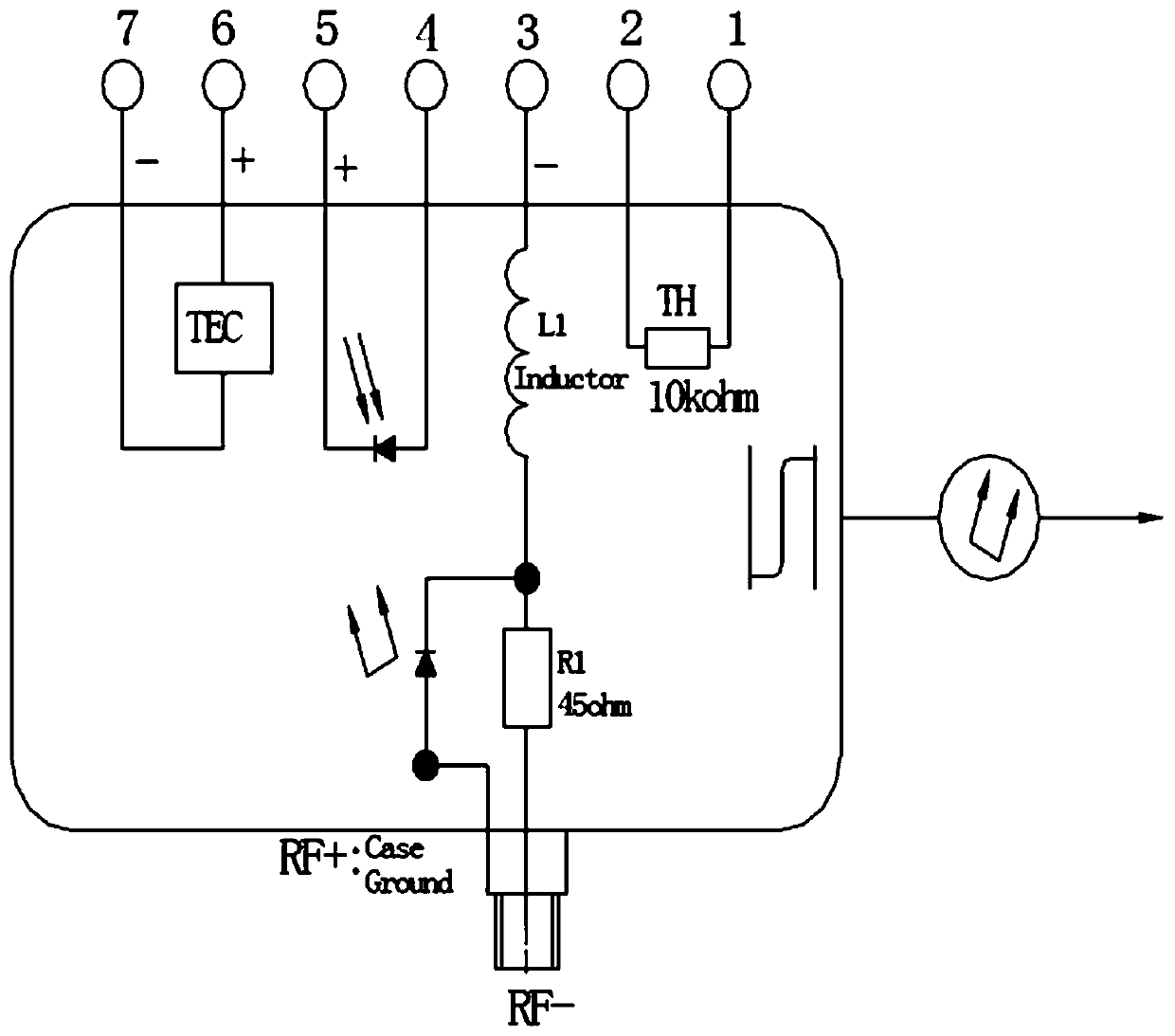

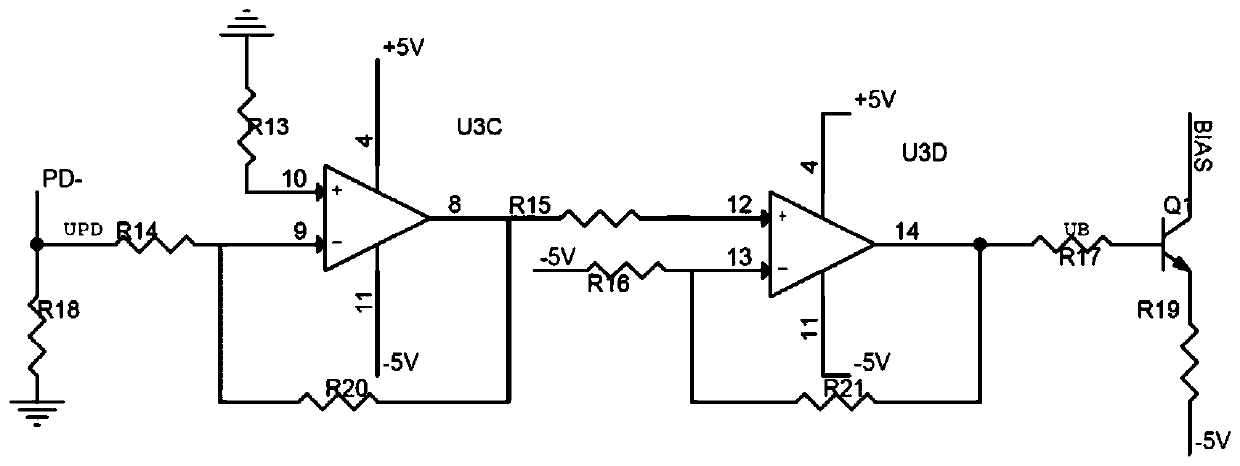

[0026] as the picture shows, figure 2 It is the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com