High-safety cable bridge

A cable tray and high-safety technology, applied in the direction of electrical components, etc., can solve the problems of burning and carbonizing the insulating layer, accelerating the aging of the insulating layer, increasing the heat generation, etc., and achieve the effects of reducing heat generation, temperature reduction, and reducing relative sliding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

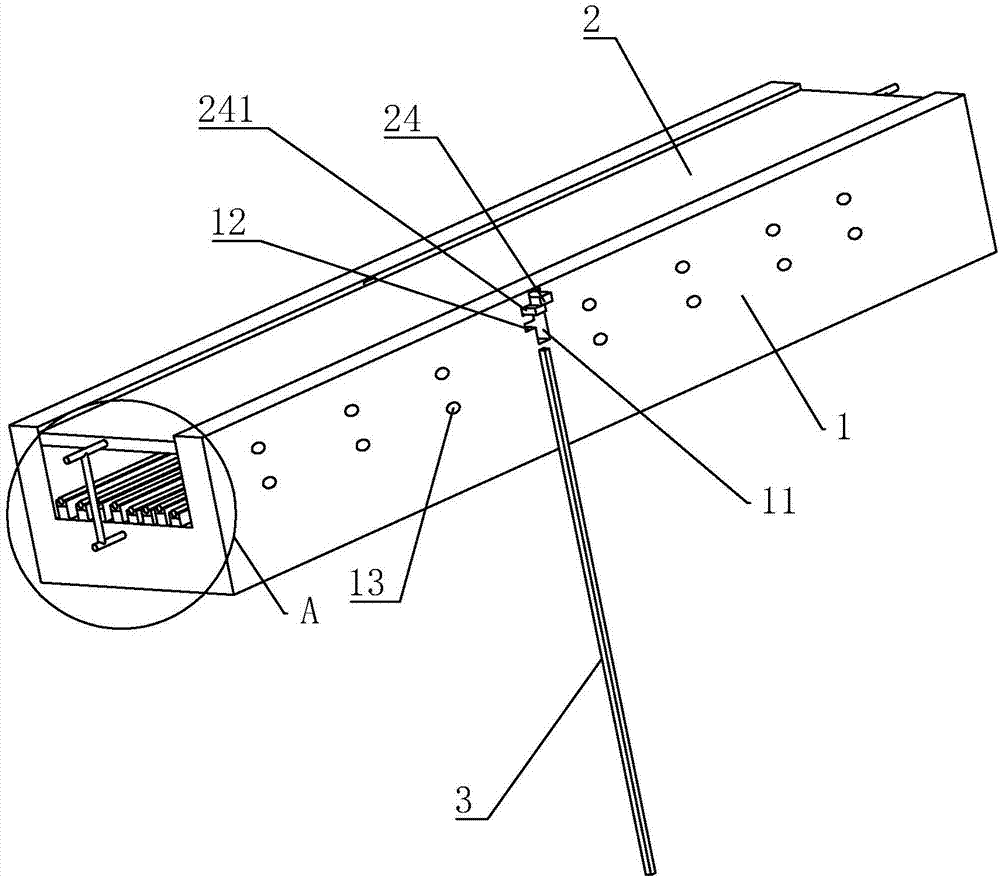

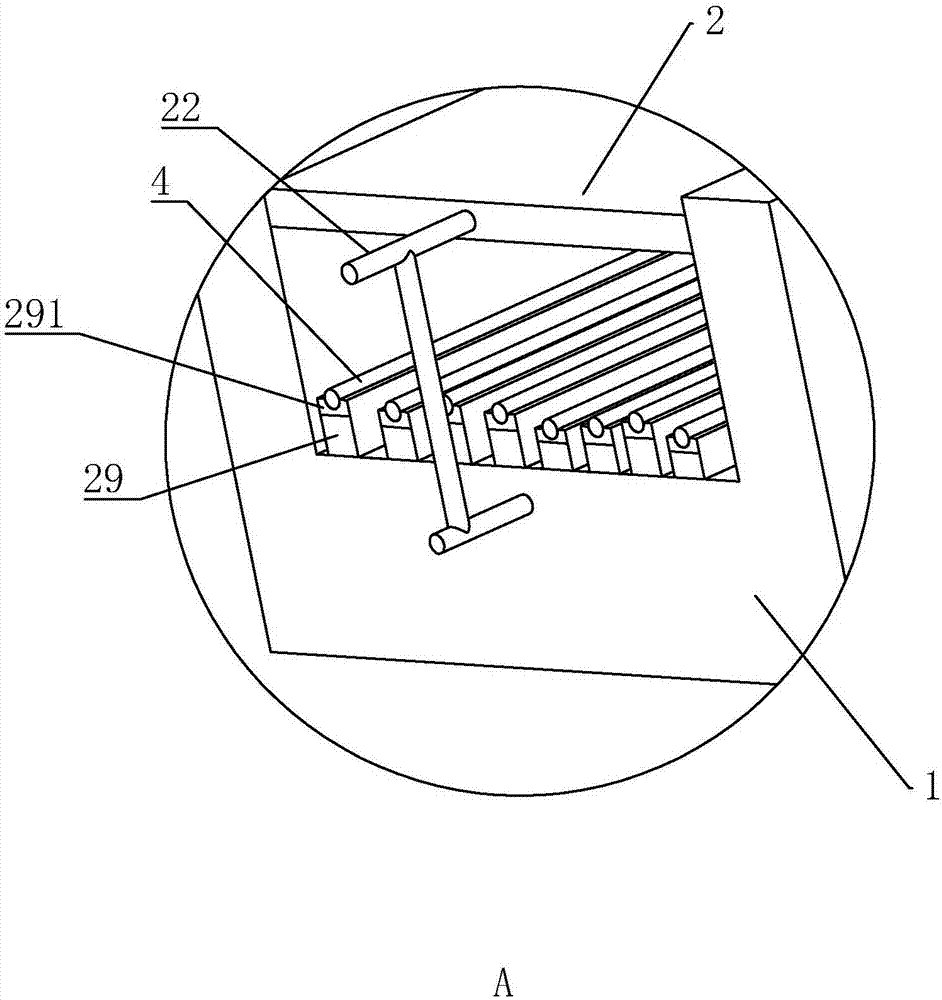

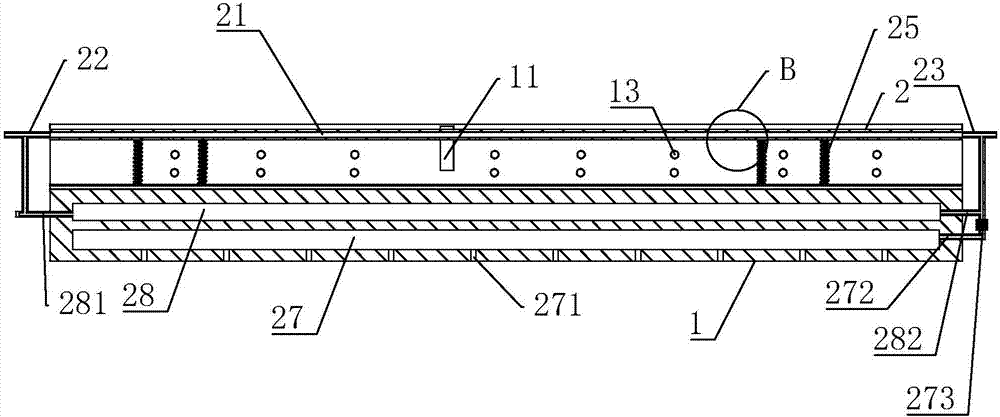

[0031] Embodiment: a kind of high security cable tray, such as figure 1 and figure 2 , including a tray 1 with a U-shaped cross-section and a cover plate 2 arranged on the upper end of the tray 1. The tray 1 is used to place the cable 4. The cover plate 2 covers the opening of the tray 1 to reduce impurities entering the tray 1. When the cable 4 When working, it generates heat by itself, and the tray 1 and cover plate 2 reduce the heat dissipation of the cable 4. At this time, there are several cooling water pipes 21 distributed in the cover plate 2, and the water inlets of each cooling water pipe 21 pass through a Water inlet pipe 22 enters water, and the water outlet of each cooling water pipe 21 is all communicated by a water outlet pipe 23 (as image 3 ), to facilitate the circulation of water in the cooling water pipe 21, when the cooling water circulates in the cooling water pipe 21, the air temperature in the tray 1 is reduced, thereby reducing the temperature of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com