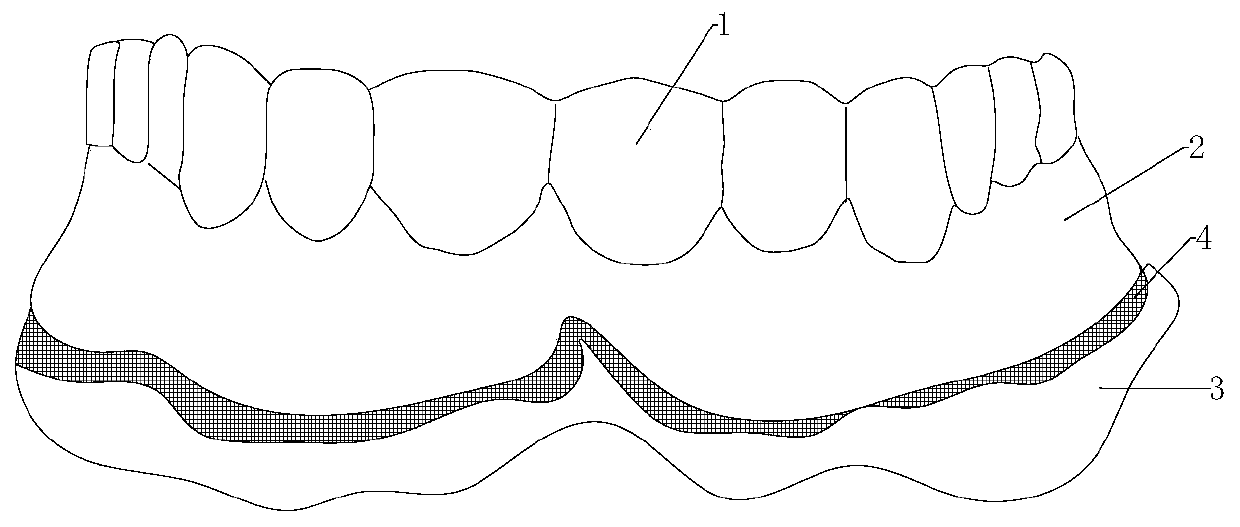

Composite denture with soft lining and preparation method thereof

A denture and soft lining technology, applied in the field of composite denture with soft lining and its preparation, can solve the problems of high price and limited application, and achieve the effects of low cost, improved retention and good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with the best embodiments.

[0031] A kind of preparation method of the artificial tooth that is compounded with soft liner, comprises the steps:

[0032] 1) Confirm the impression; according to the shape and size of the patient's dental arch, take the impression, and then produce the denture corresponding to the impression; the denture includes a hard base and artificial teeth set on the hard base;

[0033] 2) Infusion of gypsum: Inject gypsum into the denture impression obtained in step 1). After the gypsum hardens, modify the shape to obtain a plaster model containing dentures that is compatible with the shape of the patient's alveolar ridge; remove the dentures to obtain a plaster soft lining Model;

[0034] 3) Prepare the gypsum negative mold; put on the joint frame, use pl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com