Functionalized graphene modified air filter membrane and preparation method thereof

An air filtration and fossil technology, applied in chemical instruments and methods, filtration separation, separation methods, etc., can solve the problems of high air pressure drop, discomfort, single function, etc., to improve filtration efficiency, reduce air resistance, overcome pressure. drop effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Step A, prepare by the improved Hummer method Graphene oxide , Centrifugal washing and drying.

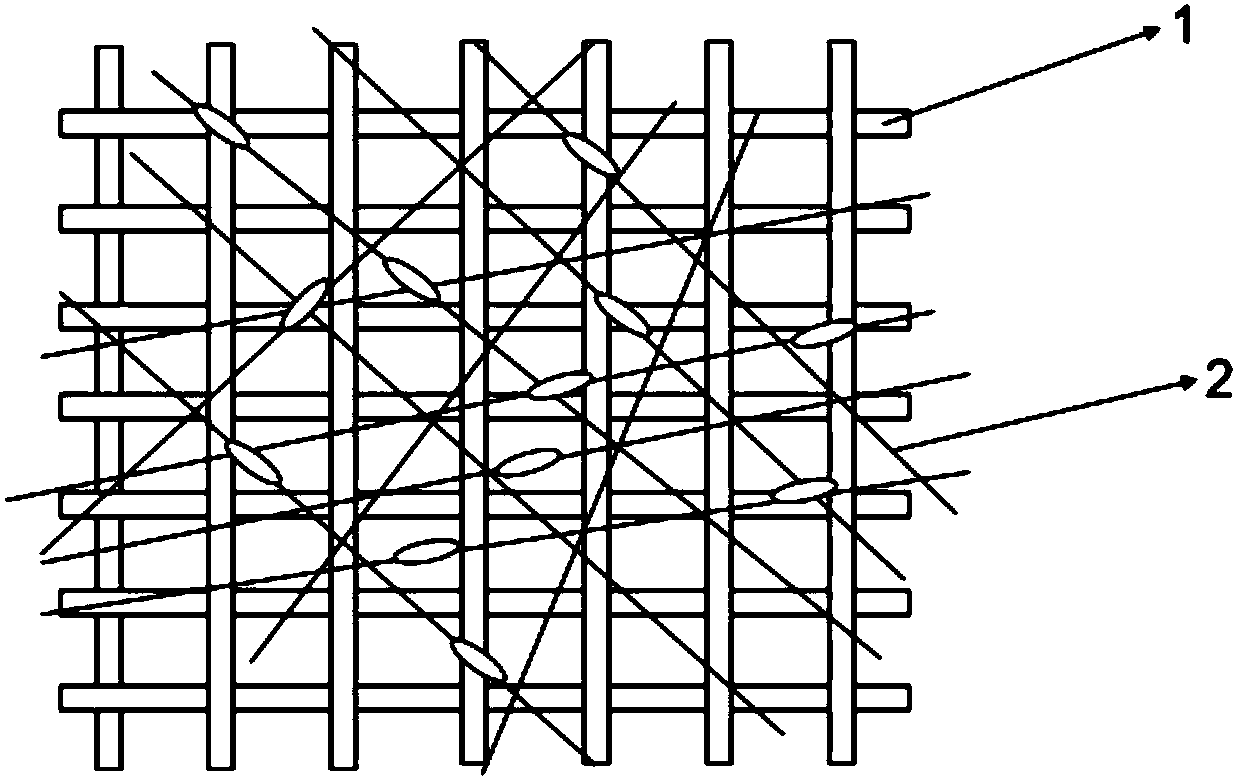

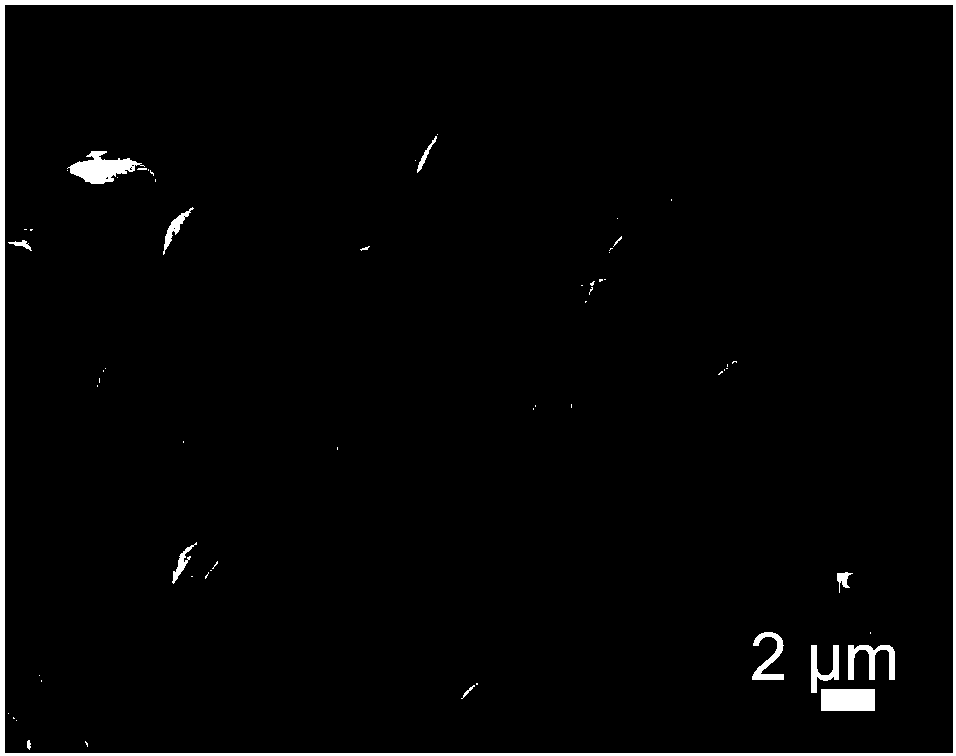

[0023] Step B, prepare 0.5mg graphene oxide / polyacrylonitrile N,N-dimethylformamide dispersion, weigh 1g polyacrylonitrile, then weigh 0.5mg graphene oxide, add 10mLN,N-dimethylformamide In the amide, stir and ultrasonic to disperse the precursor liquid evenly.

[0024] Step C. Place the aluminum foil on the electrospin receiver and place the non-woven fabric substrate on top of it.

[0025] Step D, place the prepared precursor solution on the electrospinning equipment with a syringe, the needle tip is 20.5cm away from the receiver, the voltage is 12.5kV, the advancing speed is 0.8mm / min, and 0.5mg graphene oxide The modified polyacrylonitrile composite polymer film is spun on the non-woven fabric to form a layer of dense nanofiber composite film.

Embodiment 2

[0027] Step A, prepare reduced graphene oxide, centrifuge, wash and freeze-dry.

[0028] Step B. Prepare 0.25 mg reduced graphene oxide / bisphenol A polysulfone xylene dispersion, weigh 1.5 g bisphenol A polysulfone, then weigh 0.25 mg reduced graphene oxide, add to 10 mL xylene, and stir Ultrasonic to disperse the precursor liquid evenly.

[0029] Step C, placing the aluminum foil on the electrospinning receiving substrate, and disposing the nonwoven on it.

[0030] Step D, place the prepared precursor solution on the electrospinning equipment with a syringe, the needle tip is 18cm away from the receiver, the voltage is 15kV, and the advancing speed is 1mm / min, and 0.25mg of reduced graphene oxide modified The bisphenol A polysulfone composite polymer membrane is spun on the non-woven fabric to form a dense nanofiber composite membrane.

Embodiment 3

[0032] Step A, preparation of hydroxylated graphene, centrifugal washing and drying.

[0033] Step B. Prepare 5 mg of hydroxylated graphene / polyvinyl alcohol ethylene glycol dispersion, weigh 2 g of polyvinyl alcohol, then weigh 5 mg of hydroxylated graphene, add it to 10 mL of ethylene glycol, and stir ultrasonically to make the precursor solution evenly dispersed .

[0034] Step C, placing the aluminum foil on the electrospinning receiving substrate, and disposing the nonwoven on it.

[0035] Step D, put the prepared precursor solution on the electrospinning equipment with a syringe, the needle tip is 20cm away from the receiver, the voltage is 8kV, and the advancing speed is 0.6mm / min, and 5mg of hydroxylated graphene modified The polyvinyl alcohol composite polymer film is spun on the non-woven fabric to form a dense nanofiber composite film.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap