Foam dust suppression device applicable to operation point of industrial enterprise

A technology of operating point and foam, which is applied in the direction of using liquid separation agent, separation method, and separation of dispersed particles, can solve the problems of affecting the operation of working conditions, increasing energy consumption, and not suitable for dust suppression, etc., and achieves low cost and low moisture content , good dust suppression effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

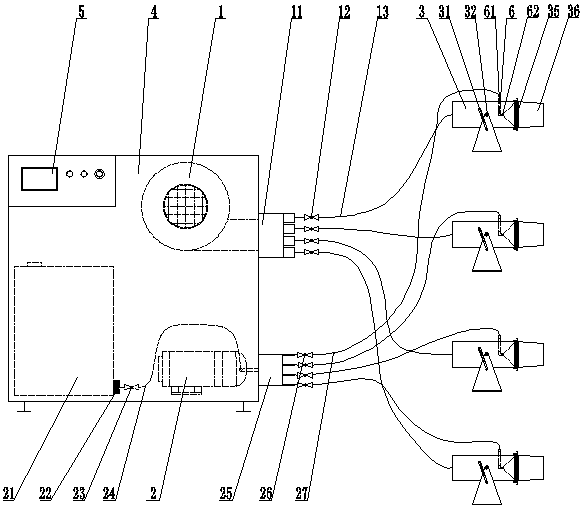

[0037] refer to figure 1 , the present embodiment includes a foam liquid pumping mechanism, an air supply mechanism, a foam generating mechanism group, a frame 4 and an electric control unit 5, and the electric control unit 5 is installed on the frame 4, and the foam liquid pumping mechanism is connected with a circuit , The air supply mechanism 1 is connected;

[0038] The foam liquid pumping mechanism is used to quantitatively send the foam liquid into the foam generating mechanism group from the foam liquid tank 21, including a liquid pump 2, a foam liquid tank 21 and a liquid distributor 25, the liquid pump 2, the foam liquid The liquid tank 21 is fixed in the frame 4, the liquid distributor 25 is installed on the frame 4, the suction port of the liquid pump 2 is connected with the liquid outlet of the foam liquid tank 21 through the pipeline I24, and the liquid The discharge port of the pump 2 is connected with the liquid inlet of the liquid distributor 25, and the liqui...

Embodiment 2

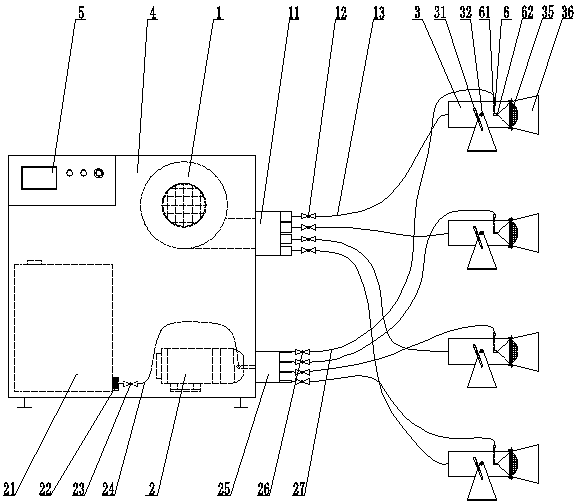

[0050] refer to figure 2 , the difference between this embodiment and embodiment 1 is:

[0051] The foam net 35 is spherical in shape;

[0052] The foam guide cylinder 36 is trumpet-shaped, with a small front end and a large rear end, and is used for guiding and controlling the sprayed foam, so that the sprayed foam is in a dispersed and close-shot state.

Embodiment 3

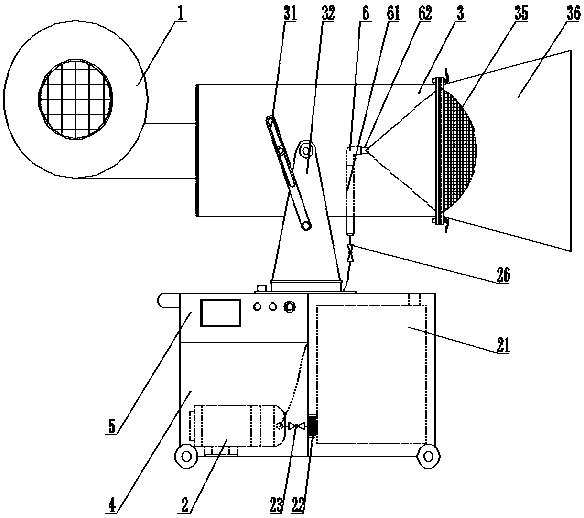

[0054] refer to image 3 , the present embodiment includes a foam liquid pumping mechanism, a blower fan 1, a foam generating mechanism, a frame 4 and an electric control unit 5; connected;

[0055] The foam liquid pumping mechanism is used to quantitatively send the foam liquid into the foam generating mechanism by the foam liquid tank 21, including a liquid pump 2 and a foam liquid tank 21, and the liquid pump 2 and the foam liquid tank 21 are fixed on the frame 4, the suction port of the liquid pump 2 is connected with the liquid outlet of the foam liquid tank 21 through a pipeline, the discharge port of the liquid pump 2 is connected with the foam generating mechanism through a pipeline, and the liquid pump 2 is output A liquid regulating valve 26 is provided at the liquid port for regulating the flow rate of the foam liquid;

[0056] The foam generating mechanism is used to generate a large number of independent foam particle groups to accurately capture the dust at the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com