A kind of preparation method of high-purity n-hexane and high-purity n-heptane

A technology of n-hexane and heptane, which is applied in the field of preparation of high-purity n-hexane and high-purity n-heptane, can solve the problems of being unsuitable for large-scale industrial production, high production cost, and high raw material requirements, and achieves low production cost and smooth production process. Easy to achieve, high product purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

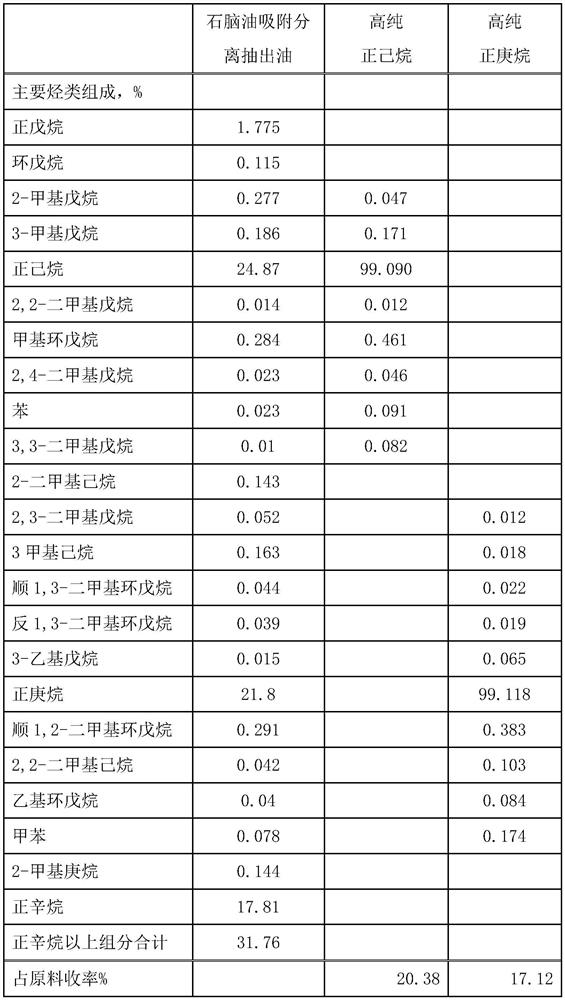

[0026] As an example in Table 1, on the rectification experimental device (10 liters still, packing plate number 30), control the reflux ratio 5-15, the naphtha adsorption separation extraction oil is carried out rectification separation, obtains high-purity n-hexane and high-purity The pure n-heptane product, hydrocarbons and yields of raw materials and products are shown in Table 1, and each composition is measured by gas chromatography.

[0027] Table 1 The hydrocarbon composition and yield of high-purity n-hexane and high-purity n-heptane products produced by rectification

[0028]

[0029]

[0030]

Embodiment 2

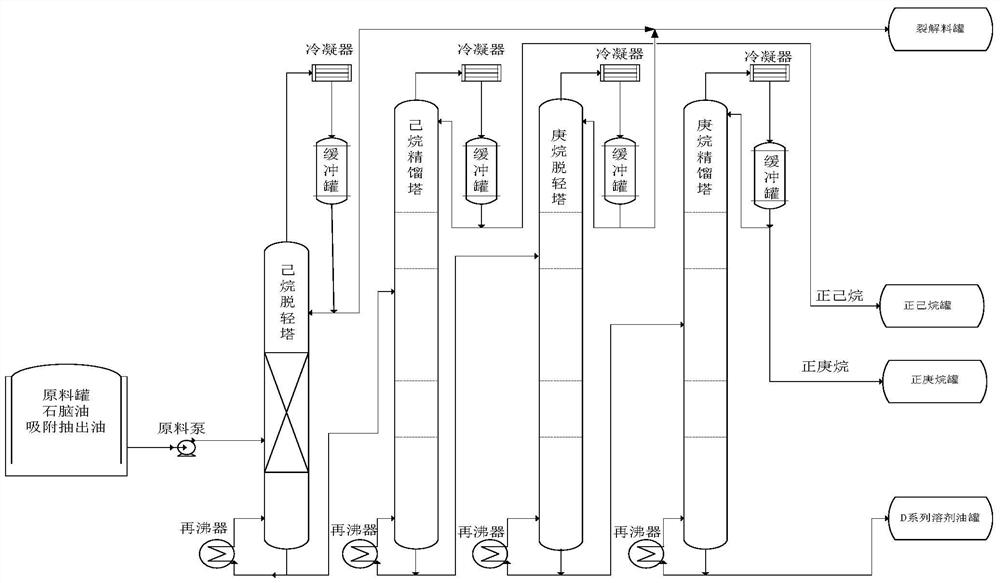

[0032] exist figure 1 On the device of the actual four-tower sequential rectification shown, according to the change in the properties of the oil raw material A and raw material B extracted from the naphtha adsorption separation, as shown in Table 2, the process parameters are adjusted. 99% high-purity n-hexane and 99% high-purity n-heptane were obtained respectively.

[0033] Table 2 Process parameters for producing high-purity n-hexane and high-purity n-heptane by four-tower sequential distillation

[0034]

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com