Bottom-argon-blowing LF furnace and auxiliary argon blowing apparatus thereof, and auxiliary argon blowing method

A technology of furnace bottom blowing and argon blowing gun, which is applied in the field of bottom blowing argon LF furnace and its auxiliary argon blowing device and auxiliary argon blowing. The implementation is simple and reliable, improving the quality of steel and the effect of improving the composition of molten steel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

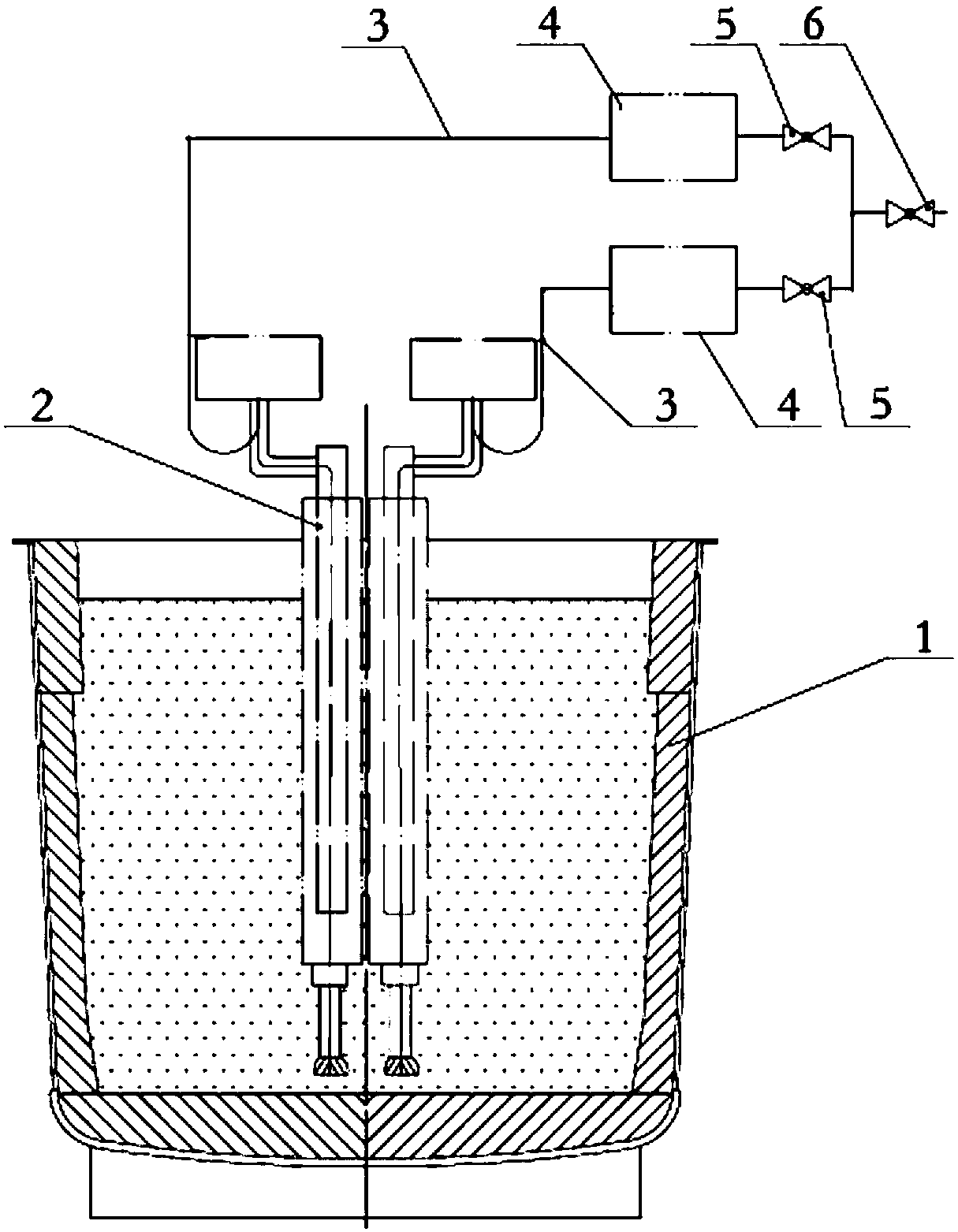

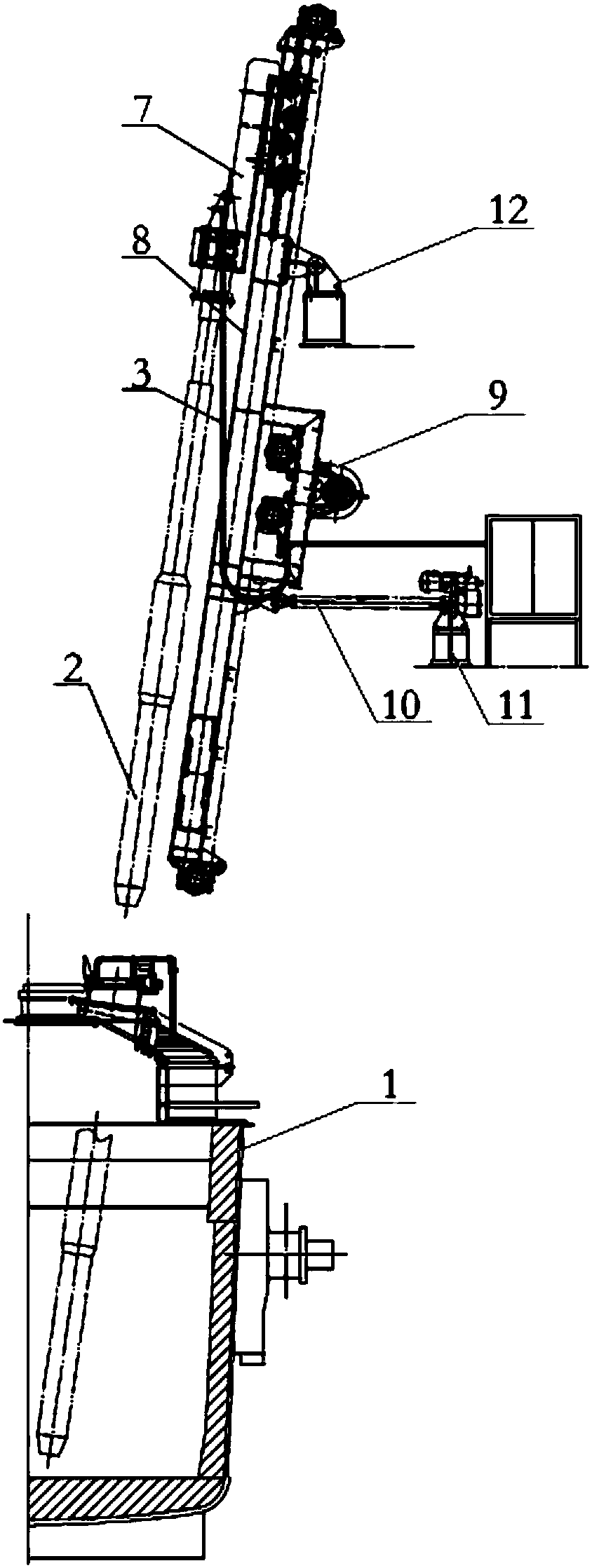

[0027] like figure 1 , the embodiment of the present invention provides an auxiliary argon blowing device based on argon blowing at the bottom of an LF furnace, including an argon blowing gun 2 for blowing argon into the furnace, and the argon blowing gun 2 is connected with an argon supply pipeline 3 and It is used to drive the driving mechanism for switching between the standby position outside the furnace and the working position inside the furnace. The argon gas supply pipeline 3 is provided with a flow control unit.

[0028] The auxiliary argon blowing device provided in this embodiment can timely carry out auxiliary argon blowing in the furnace when the argon blowing at the bottom of the LF furnace is insufficient or fails, so as to ensure the smooth progress of production and avoid the service life of the ladle due to excessively increasing the flow rate of argon blowing at the bottom. impact, and can avoid the operation of repacking or the downgrading of molten steel. ...

specific Embodiment

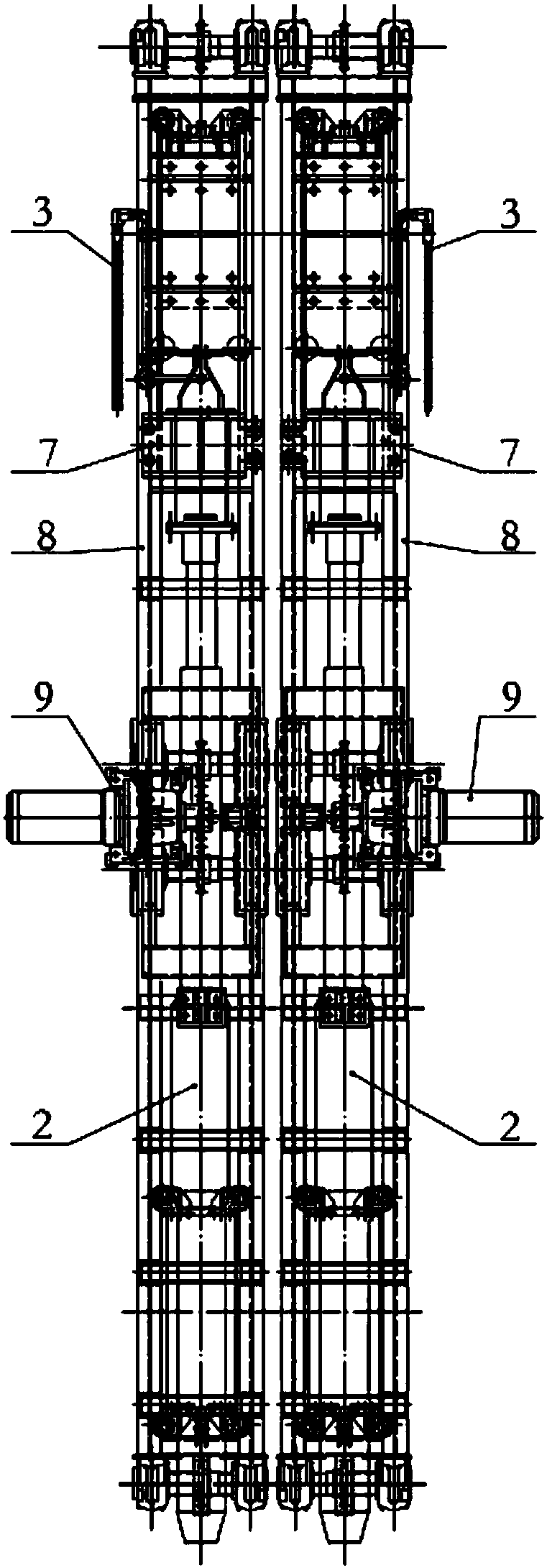

[0038]The lift drive structure includes a trolley track frame 8, a lift trolley 7, and a lift drive unit 9 that is connected to the lift trolley 7 and drives the lift trolley 7 to walk on the trolley track frame 8. The trolley track frame 8 Arranged above the furnace body 1, the argon blowing gun 2 is installed on the lifting trolley 7; the axis of the argon blowing gun 2 is parallel to the track length direction of the trolley track frame 8, and the lifting trolley 7 is driven on the corresponding Sliding on the dolly track frame 8 can drive the argon blowing gun 2 up and down. The above-mentioned lifting drive unit 9 can adopt a cylinder, a hydraulic cylinder or an electric push rod whose drive shaft is parallel to the axis of the argon blowing gun 2; in another embodiment, the lifting drive unit 9 includes a reduction motor, a transmission sprocket, a guide The sprocket and the transmission chain constitute a chain transmission structure. By connecting the lifting trolley 7...

Embodiment 2

[0042] like figure 1 , the embodiment of the present invention relates to a bottom blowing argon LF furnace, including a furnace body 1, the bottom of the furnace body 1 is equipped with a ventilating brick, and is also equipped with an auxiliary argon blowing device, and the auxiliary argon blowing device is preferably the above-mentioned embodiment one The specific structure of the provided auxiliary argon blowing device based on LF furnace bottom blowing argon will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com