Permanent-magnet switch reluctance motor with axially-magnetized rotor

A permanent magnet switch, axial magnetization technology, applied in electrical components, electromechanical devices, magnetic circuit static parts, etc., can solve the problems of motor magnetic energy expansion limitation, difficulty in implementing magnetic isolation measures, affecting the structural strength of the motor, etc. Simple and reliable installation, wide electromagnetic energy conversion area and large number of magnetic poles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below with reference to the accompanying drawings and embodiments.

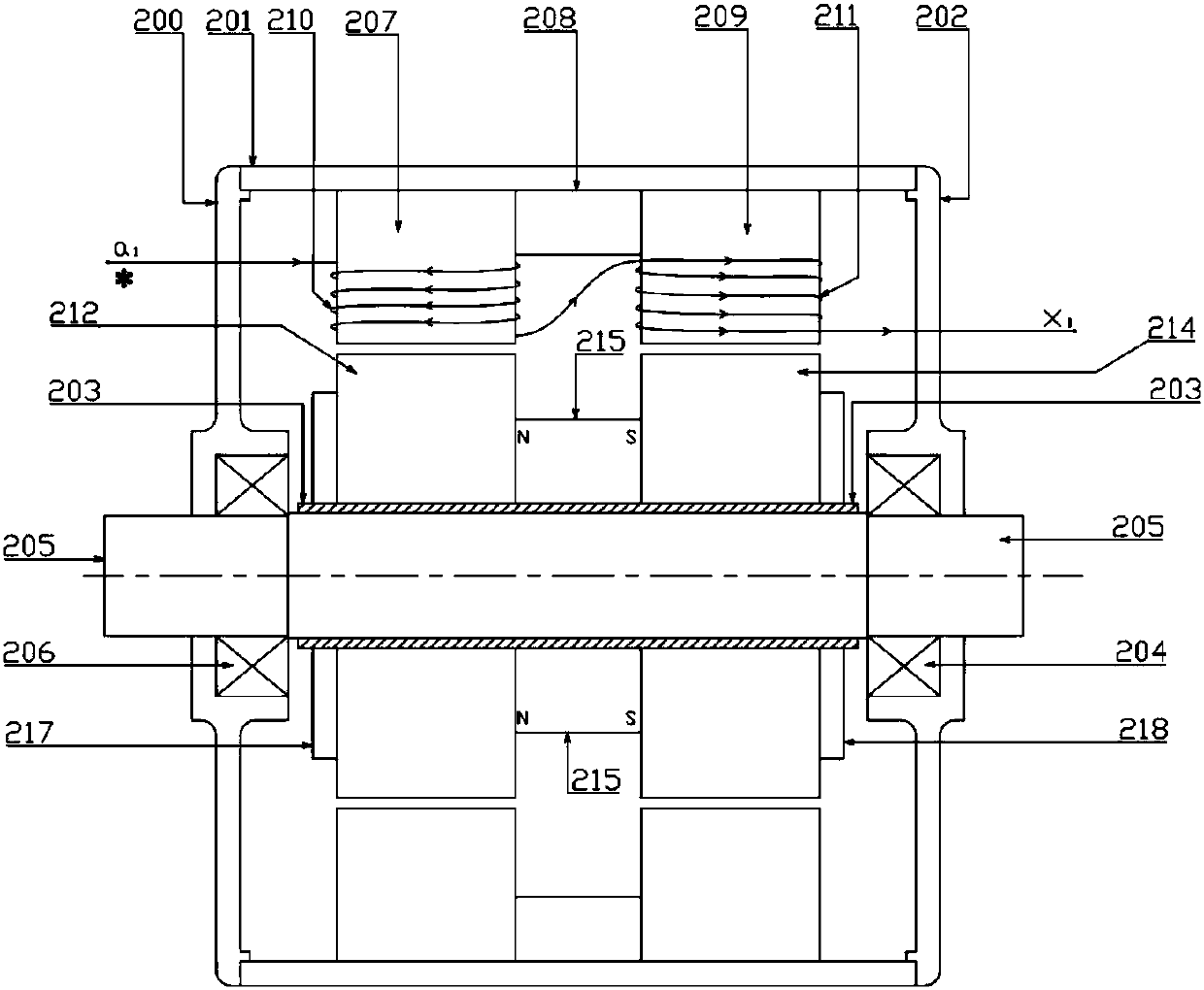

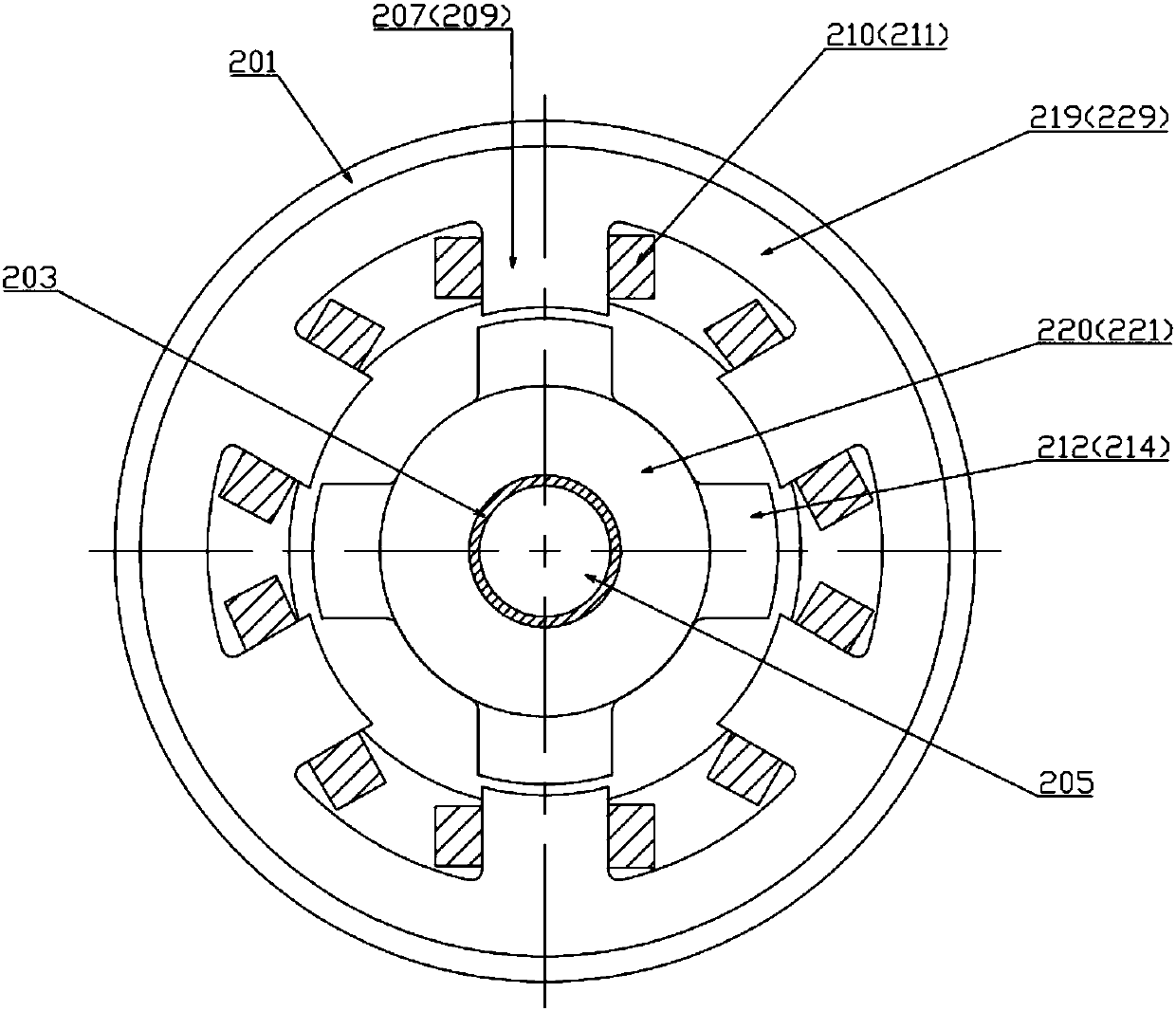

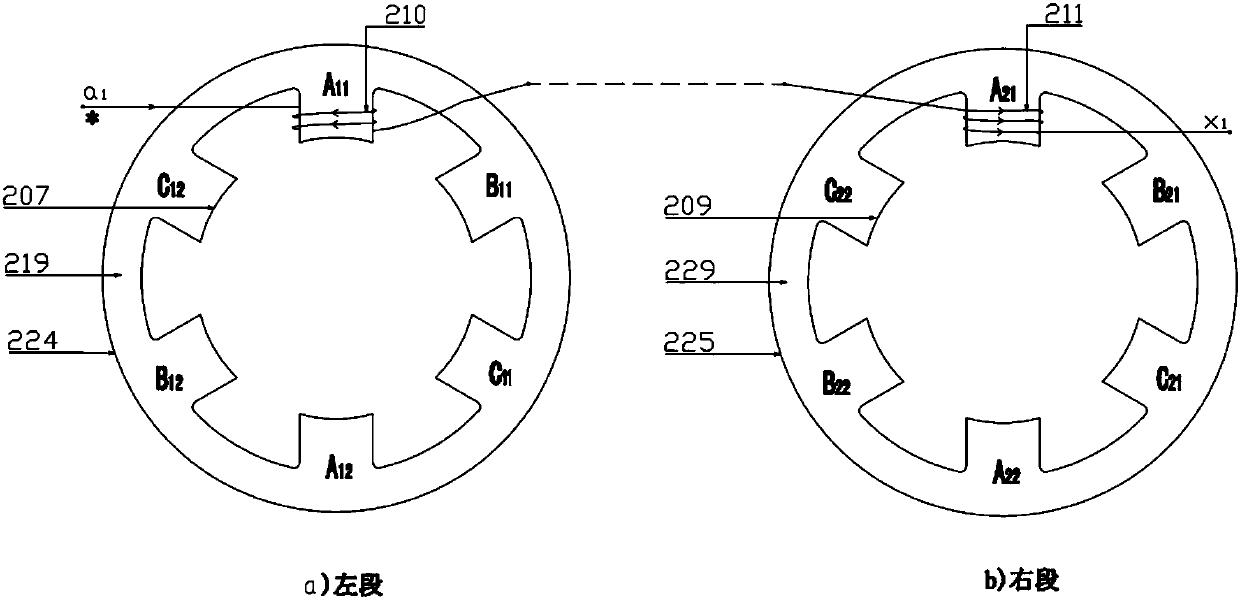

[0034] like Figure 1-Figure 4 As shown, the present invention includes a motor housing 201, a stator and a rotor. The motor housing 201 is fixed on the machine base by fixing screw holes and bolts. The motor housing 201 is provided with a left end cover 200 and a right end cover 202 at both ends, and the right end cover 202 is provided with a rotor. A position sensor is used to detect the position of the rotor; the stator includes a left-segment stator core 224, a right-segment stator core 225 and an inter-segment yoke 208 embedded between the left and right stator cores with the same structure. The yoke 208 connects the left and right stator cores to form a two-segment integral stator.

[0035] The left stator core 224 includes the left stator yoke 219 and the left stator magnetic poles 207 distributed on the inner ring of the stator left yoke 219, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com