Tillage-free sower

A seeder and seed box technology, applied to agricultural machinery and implements, shovels, plows, etc., can solve the problems of affecting seeding efficiency, poor land conditions, easy accumulation, etc., and achieve the effect of improving the efficiency of crushing soil and improving the seeding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

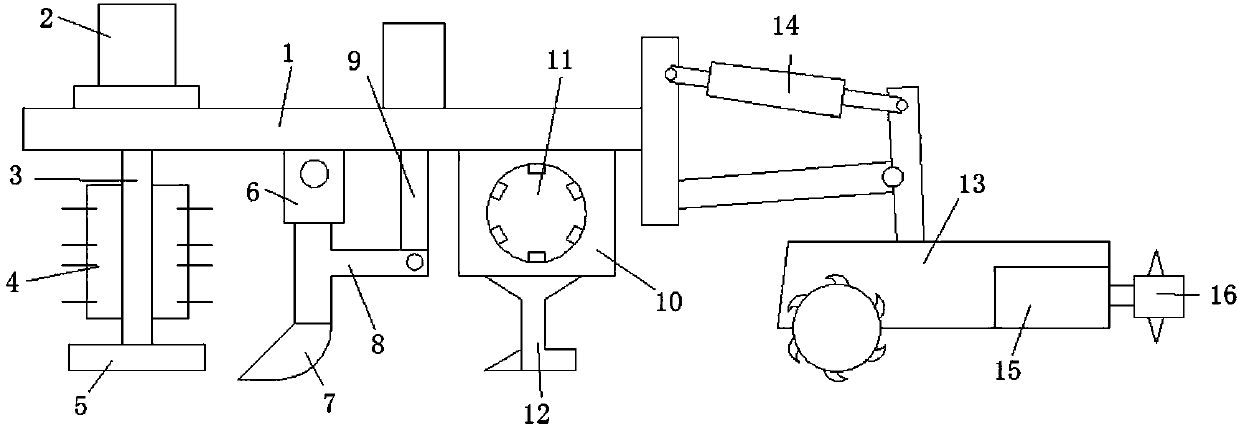

[0011] Referring to the accompanying drawings, a no-tillage seeder includes a beam plate 1, a motor 2 is fixedly mounted on the front end of the beam plate 1, a rotating shaft 3 is connected to the lower end of the motor 2, and a shaft 3 is provided on the side wall of the rotating shaft 3. Weed roller 4, the lower end of described weed roller 4 can be provided with cutting disk 5, one side of described motor 2 is provided with coulter frame 6, and the lower surface of described coulter frame 6 is hinged with coulter 7, so The side wall of the coulter 7 is provided with a connecting rod 8, the end of the connecting rod 8 is hinged to the piston rod, and the connecting rod can adjust the depth of cultivation under the control of the piston rod 9. One side is provided with seed box 10, and described seed box 10 is provided with roller 11, and the lower end of described seed box 10 is communicated with sowing pipeline 12, and the afterbody of described beam plate 1 is hinged with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com