Apparatus and method for on-line sampling and detecting of lifting type tobacco strip for threshing and redrying factory

A detection device, leaf threshing and re-roasting technology, applied in the direction of measuring device, optical device, cleaning device, etc., can solve the problems of complicated sampling inspection process, high labor intensity, poor timeliness, etc., achieve online automatic detection, reduce work Strength, work efficiency improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

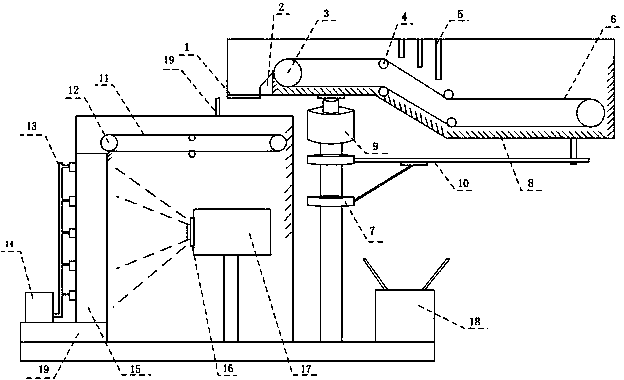

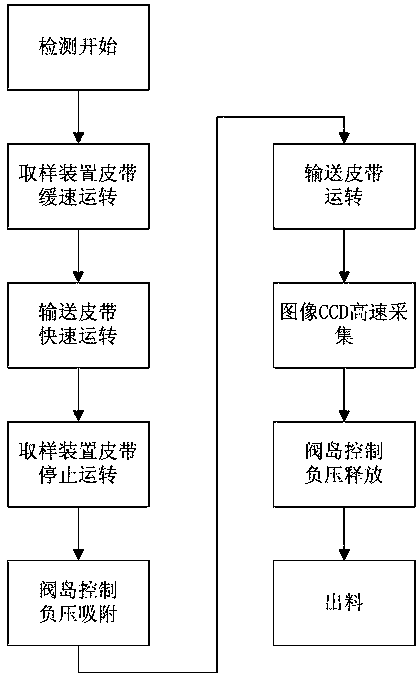

[0027] Such as figure 1 and 2 As shown, the present invention includes a lift-type tobacco on-line sampling and detection device for threshing and redrying plants, including a sampling device, a tobacco transmission device, a tobacco detection device and a controller for controlling the above-mentioned various devices. The discharge port of the sampling device is arranged directly above the laminar tobacco conveying device, the discharge port of the laminar tobacco conveying device is arranged above the feed port of the laminar tobacco detection device, and the discharge port of the laminar tobacco detection device is provided with an outlet material belt 19;

[0028] The sampling device includes a sampling chamber and a first DC motor 3 arranged inside the sampling chamber, a first conveying belt 6, a stepper motor 9 arranged at the bottom of the sampling chamber, and a material-taking chamber arranged at the top of the sampling chamber. The container, the material retrievi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com