Punching device

A technology of stamping device and stamping die, applied in the direction of feeding device, positioning device, storage device, etc., can solve the problems of blockage of stamping parts, affecting the dimensional accuracy of stamping, difficult operation, etc., and achieve the effect of high stamping efficiency and less power devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in further detail below by means of specific embodiments:

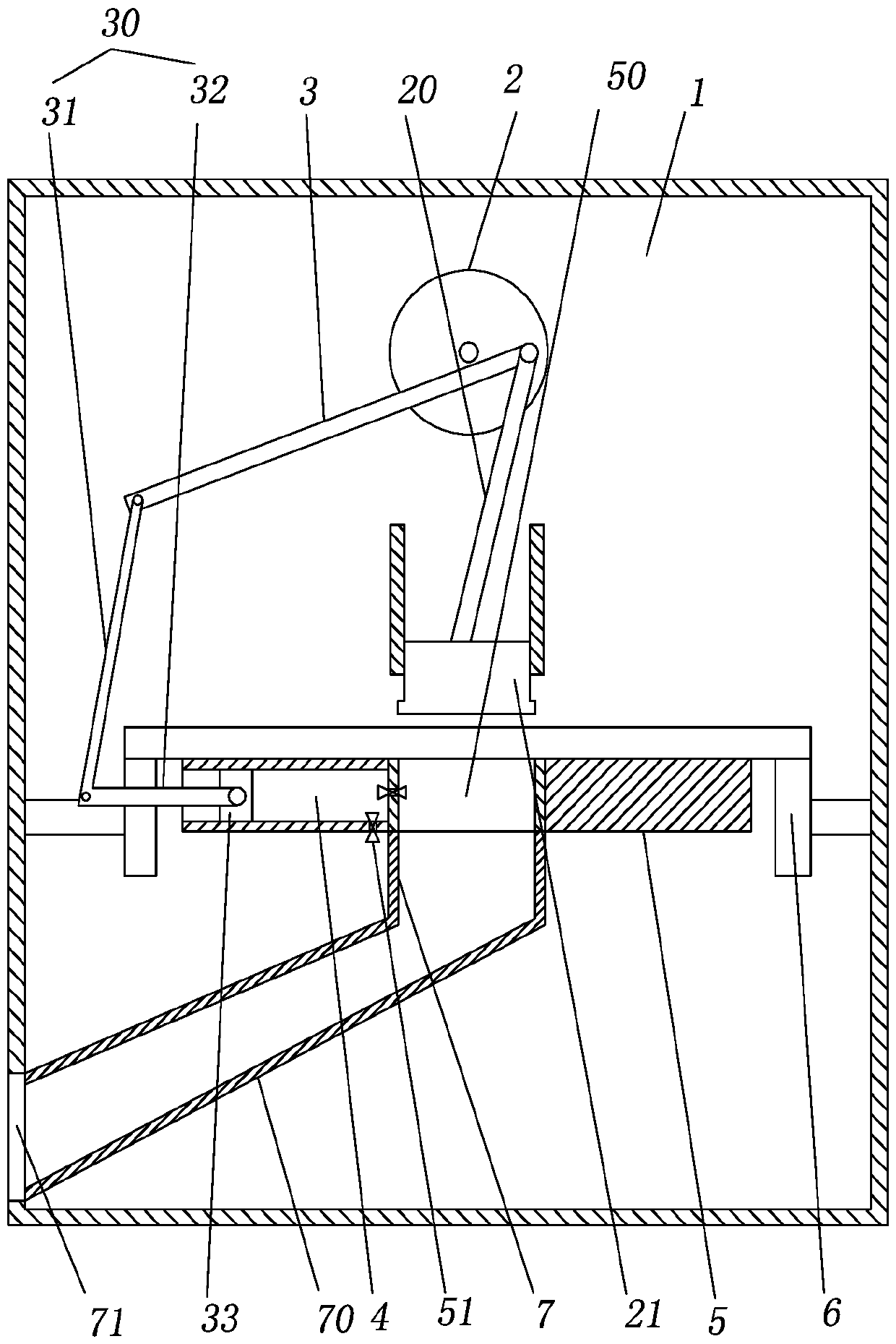

[0018] The reference signs in the drawings of the description include: stamping box 1, crank 2, stamping rod 20, stamping head 21, swing rod 3, blowing rod 30, first rod 31, second rod 32, piston 33, sliding cavity 4 , stamping die 5, stamping hole 50, one-way valve 51, conveying roller 6, straight pipe 7, inclined pipe 70, discharge port 71.

[0019] The embodiment is basically as attached figure 1 Shown: stamping device, including motor, stamping die 5, stamping box 1 and stamping head 21 located above stamping die 5, stamping die 5 is provided with punching hole 50, also includes power mechanism, blowing mechanism and for conveying steel plate The conveying mechanism; the power mechanism includes a crank 2 and a stamping rod 20, the output shaft of the motor is connected to the crank 2, one end of the stamping rod 20 is hinged to the crank 2, the other end of the stam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com