Centering device for steel tube welding

A centering device and steel pipe technology, applied in the field of steel pipes, can solve the problems of poor control of cutting angle, time-consuming and labor-intensive cutting, etc., and achieve the effects of manpower saving, convenient welding and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

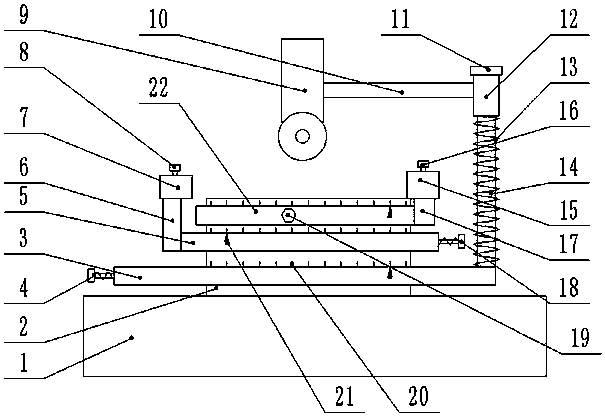

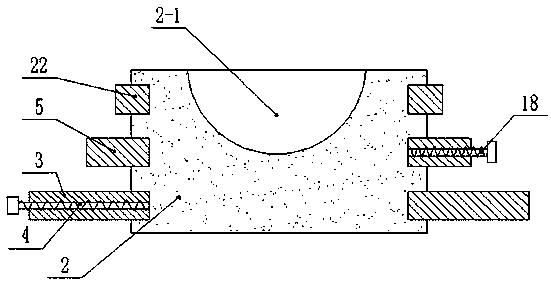

[0014] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

[0015] like Figure 1-2 As shown, a steel pipe welding centering device includes a bottom plate 1, a worktable 2 is fixed on the upper part of the bottom plate 1, an arc-shaped groove 2-1 is provided on the upper surface of the workbench 2, and the workbench 2 is a cylinder Shaped, the outer ring of the workbench 2 is provided with three grooves at intervals, and the three grooves of the workbench 2 from bottom to top are respectively rotatably connected with an annular ring A3, an annular ring B5 and an annular ring C22. The side ends of the ring A3, the annular ring B5 and the annular ring C22 are screwed with the set screw A4, the set screw B18, and the set screw C19 respectively, and the side end of the annular ring B5 is fixed with a vertical pole A6, and the pole A6 A sleeve A7 is fixed on the sleeve A7, and a locking screw A8 is screwed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com