A variable arc mechanism

A variable, arc technology, applied in the direction of metal processing mechanical parts, manufacturing tools, workpiece clamping devices, etc., can solve the problems of processing, profiling, and clamping cannot be carried out effectively and efficiently, and achieve high arc accuracy, Good stability and the effect of improving arc accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

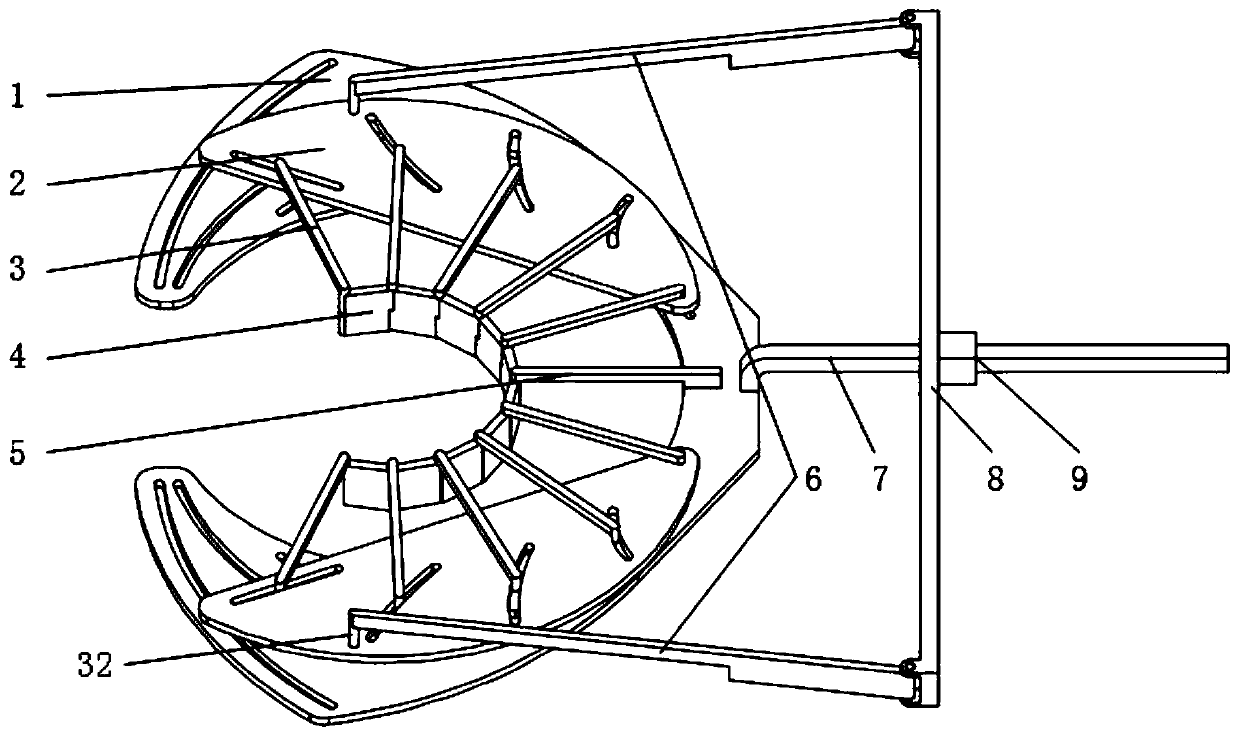

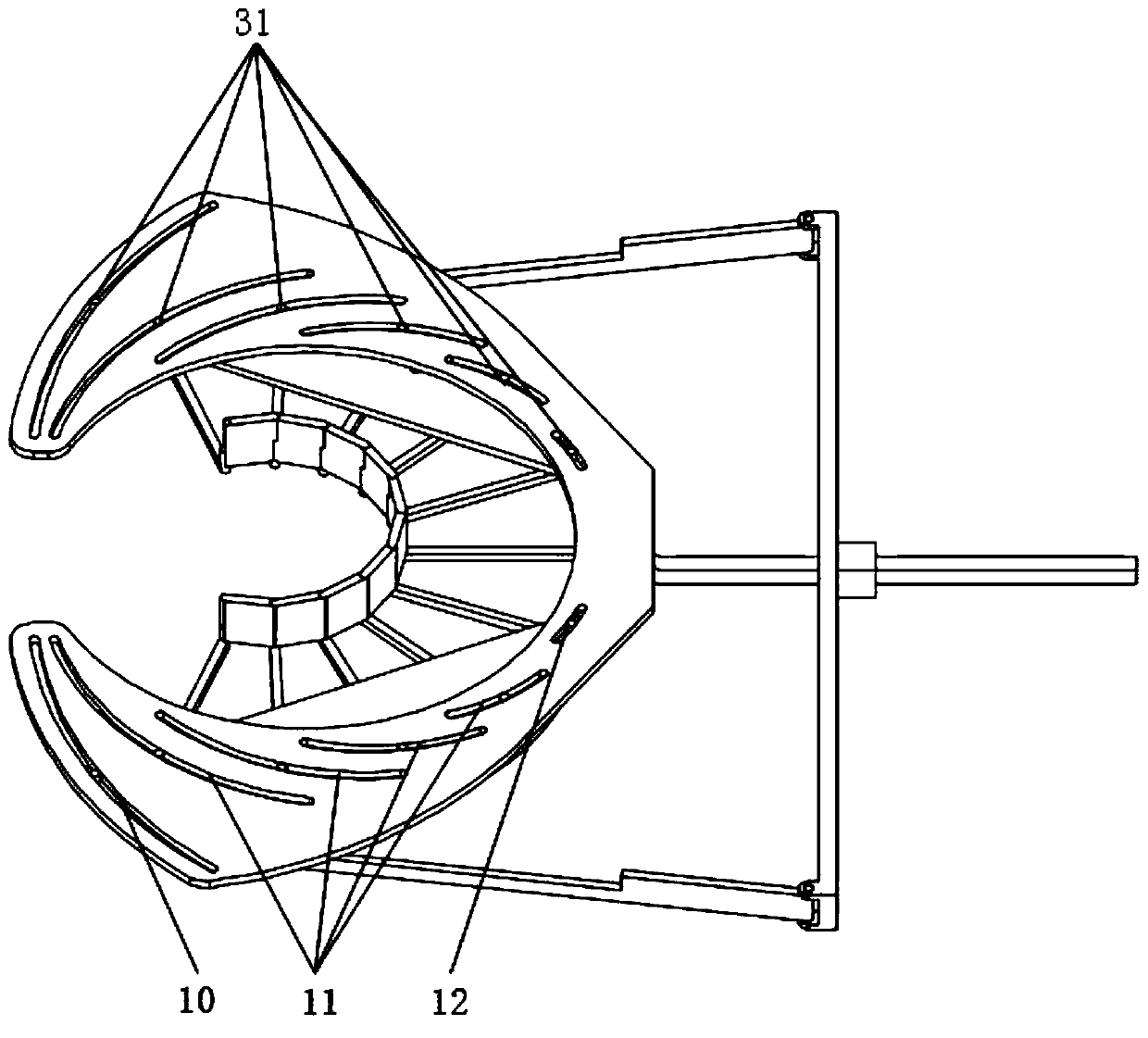

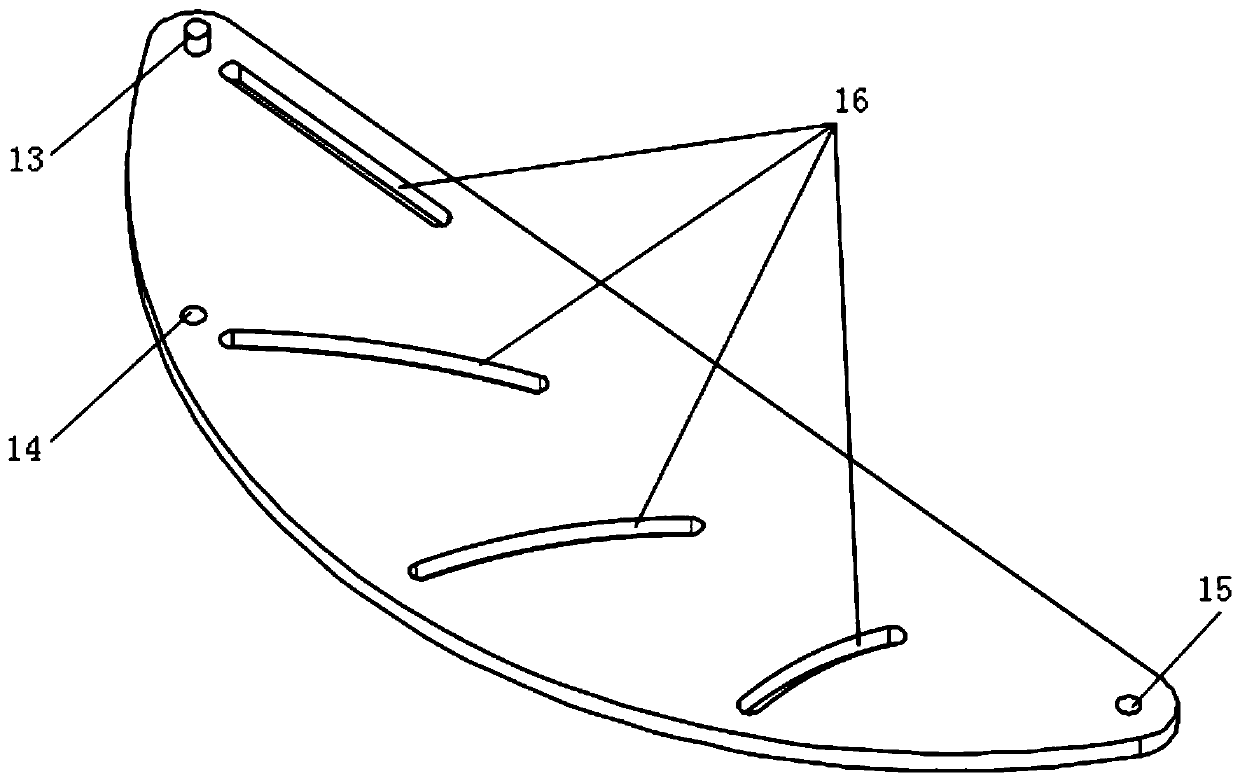

[0026] see Figure 1 to Figure 3As shown, the variable arc mechanism described in this embodiment includes an actuating part and a driving part, and the actuating part includes a fixed slide 1, a moving slide 2, a dynamic variable arc support rod 3, and a rigid arc 4 , fixed and variable arc support rod 5, the driving part includes a driving transmission rod 6, a moving pair guide rod 7, a driving push rod 8, and a moving pair slider 9; the fixed sliding plate 1 is designed as a jaw structure, and The left and right parts are mirror images, and each part is formed with a first chute (specifically an arc-shaped trough) distributed along its respective shape trajectory, and the length of the first chute gradually decreases from the opening of the jaw, that is, close to the The first chute at the opening of the jaw is the longest, which is 10 shown in the figure, and the first chute near the tail of the jaw is the shortest, which is 12 shown in the figure, and 11 shown in the fig...

Embodiment 2

[0029] The difference from Embodiment 1 is that in this embodiment, the fixed variable arc support rod 5 is replaced by a dynamic variable arc support rod (not shown in the figure), so that the variable arc can obtain a degree of freedom, that is, along the circle The degree of freedom of rotation in the direction of rotation of the arc center, so that high arc accuracy, high rotation radius accuracy, high stability and high adaptability can be performed within a small rotation range, so that the arc can change its radius statically and dynamically Movement along an arc is possible.

Embodiment 3

[0031] The difference from Embodiment 1 is that the support rod of this embodiment only retains the dynamic and variable arc support rod 3 that cooperates with the movable slide, instead of using the fixed and variable arc support rod 5, that is, at the tail of the fixed slide 1 Support rod (not shown in the figure) is installed no longer in the center.

[0032] To sum up, the whole mechanism of the present invention can complete the variable diameter adjustment of the circular arc formed by the rigid arcs during the movement of the moving sub-slider 9, realizing the possibility of taking the outside as an entity and the center as a hollow. The research and development of the variable arc mechanism has achieved the purpose of variable control of the arc. The movable secondary guide rod and the fixed sliding piece of the mechanism can be fixed together in many different ways, and can also be processed as a whole in the same piece of material, and the production cost is low. In...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com