A kind of processing method of anti-fouling advertising inkjet material

A technology of inkjet materials and processing methods, which is applied in the field of fabrics, can solve the problems of no processing methods and no antifouling performance of advertising inkjet materials, and achieve the effect of convenient processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

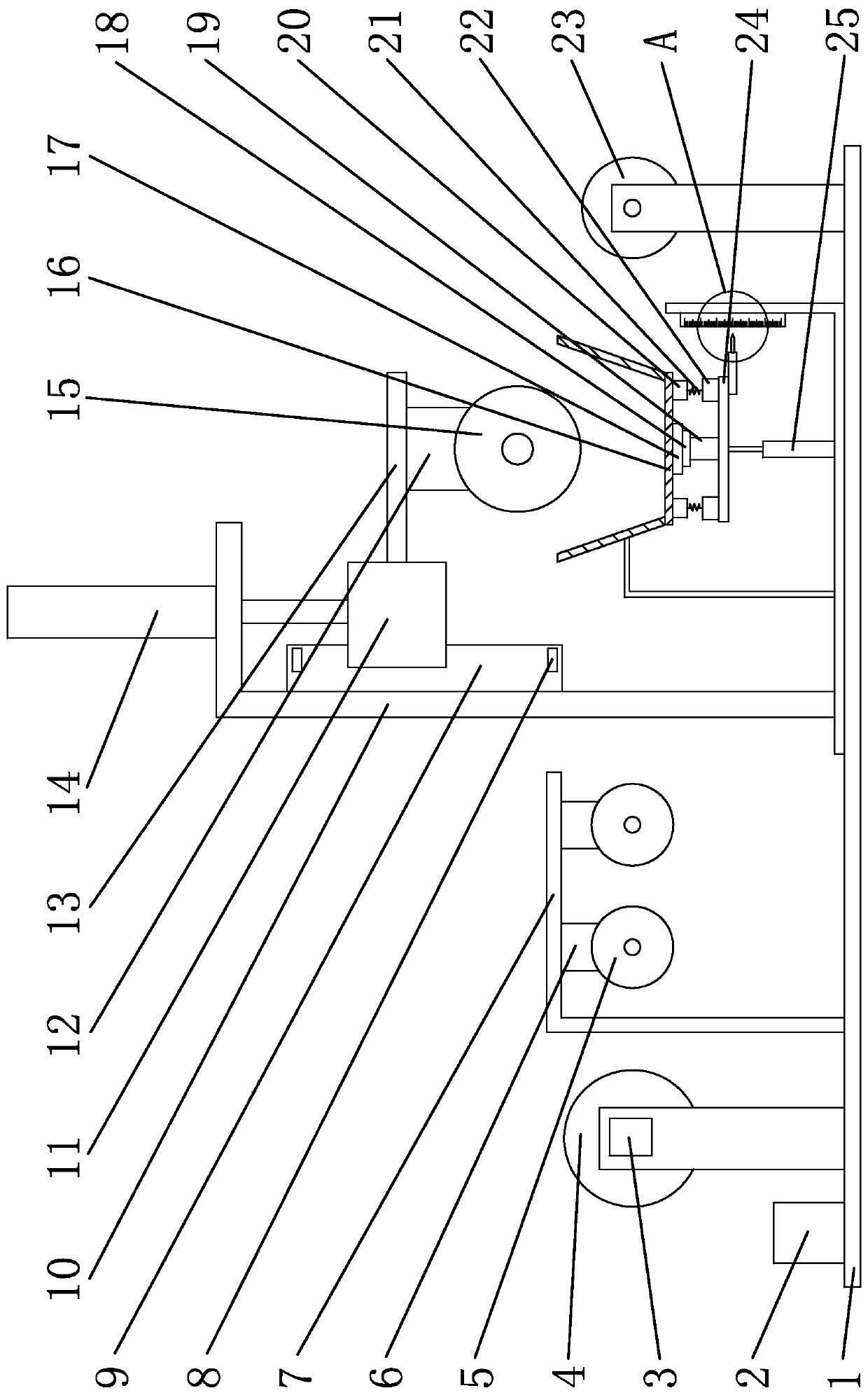

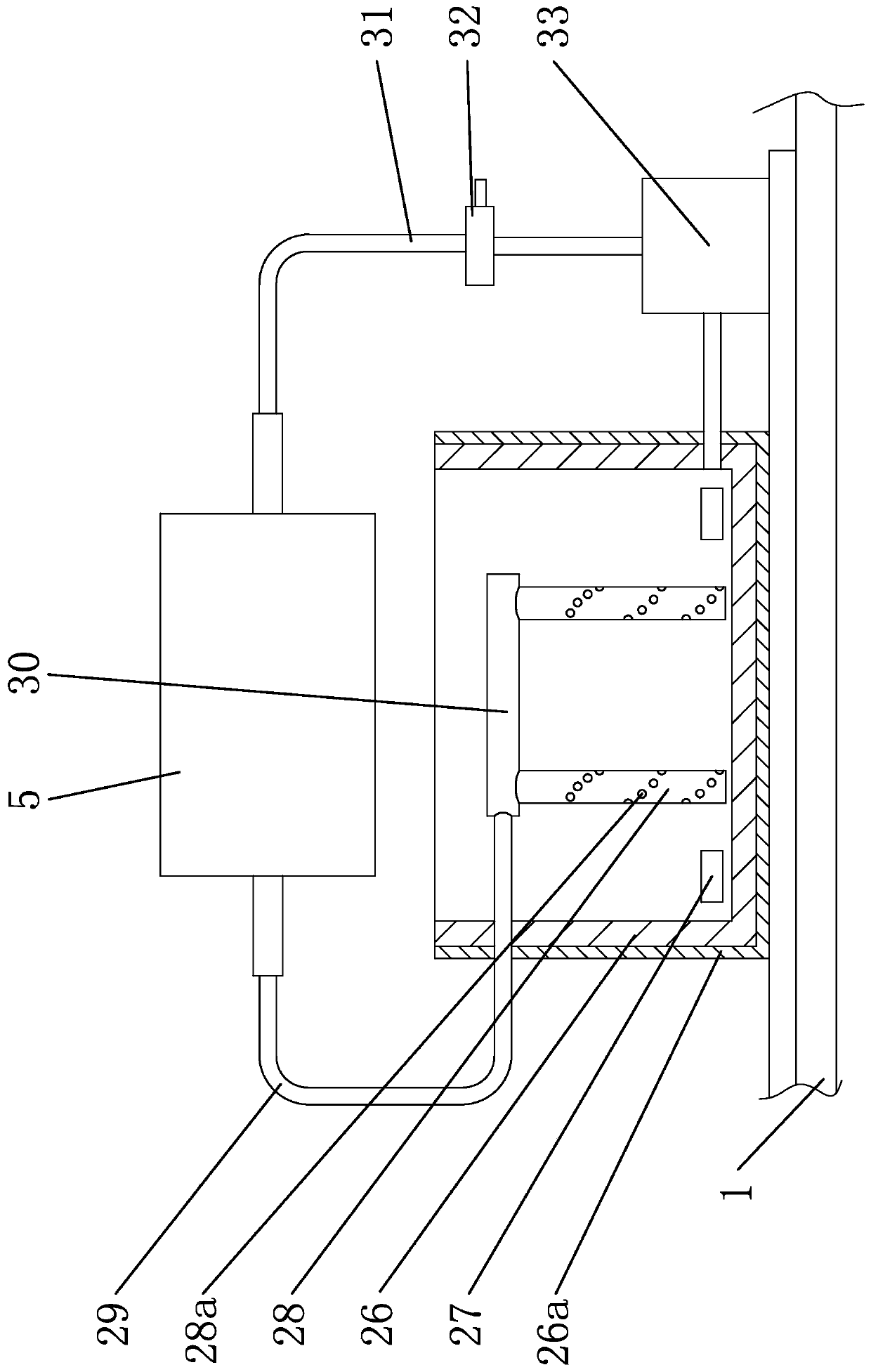

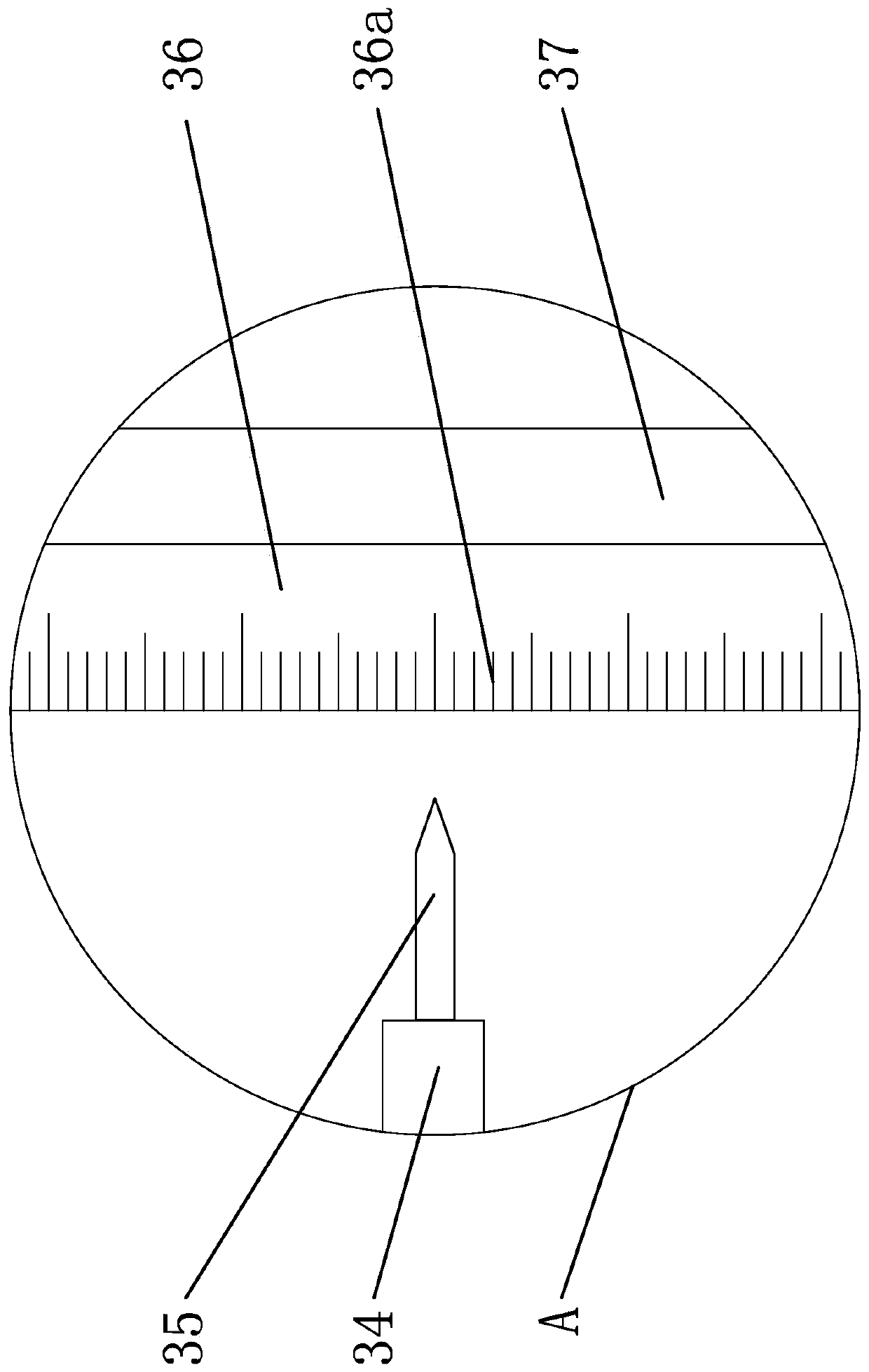

[0042] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

[0043] The processing method of this anti-fouling advertisement inkjet material comprises the following steps:

[0044] a. Outsourcing: purchase existing polyester fabrics and PVC films on the market, and conduct appearance inspections on them;

[0045] b. Ingredients: by weight, weigh 25-35 parts of polyacrylic resin, 5-10 parts of epoxy resin, 7-11 parts of silicon dioxide, 10-16 parts of titanium white paste, and 2-5 parts of plasticizer , 0.4-0.8 parts of dispersant, 0.1-0.4 parts of fungicide, 0.6-1.2 parts of colorant, 20-40 parts of ethanol and 12-24 parts of ethyl acetate are put into the mixer and stirred for 40-60 minutes. Prepared coating; In the present embodiment, weigh 28 parts of polyacrylic resins, 6 parts...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com