A convenient mechanical parts processing equipment and using method

A technology for mechanical parts and processing equipment, applied in the field of mechanical parts processing, can solve the problems of generating a large amount of waste, damage to processing equipment, adverse effects on the working environment and users, and achieves improved cleaning quality, improved work efficiency, and achieved The effect of non-stop continuous operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

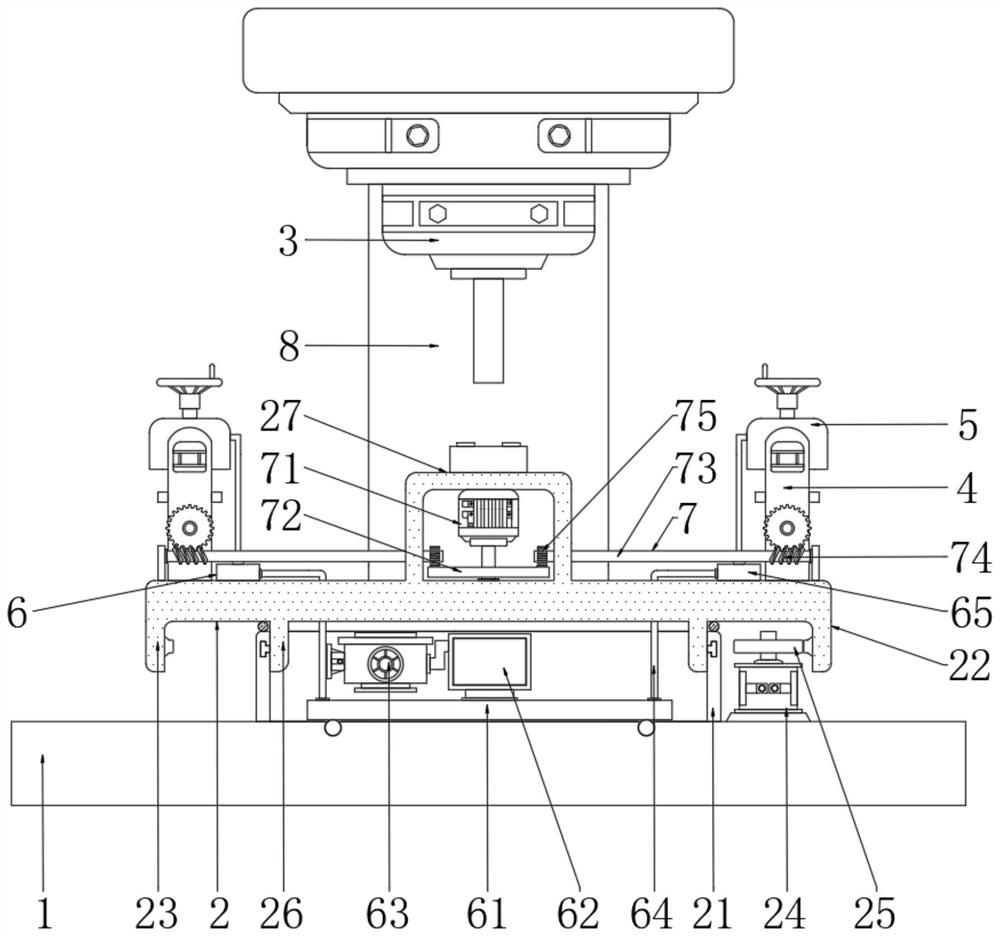

[0024] Embodiment 1: An easy-to-use mechanical parts processing equipment, please refer to 1, including base 1 and processing equipment main body 3, processing equipment main body 3 is widely used in this field, and its structure and principle are well known to those skilled in the art , those skilled in the art can choose flexibly, and will not be described in detail here. The electrical components appearing in the present invention are all connected to the external main controller and 220V mains, and the main controller can be controlled by a computer, etc. Conventional known equipment, specifically, a battery is fixed on the top of the installation shell 27, and the servo motor 71 and the servo motor 46 are both electrically connected to the battery, so that the rotation of the workbench 22 will not affect its use;

[0025] Please refer to 1. There is a continuous operation table 2 on the top of the base 1. The continuous operation table 2 is convenient for fixing multiple s...

Embodiment 2

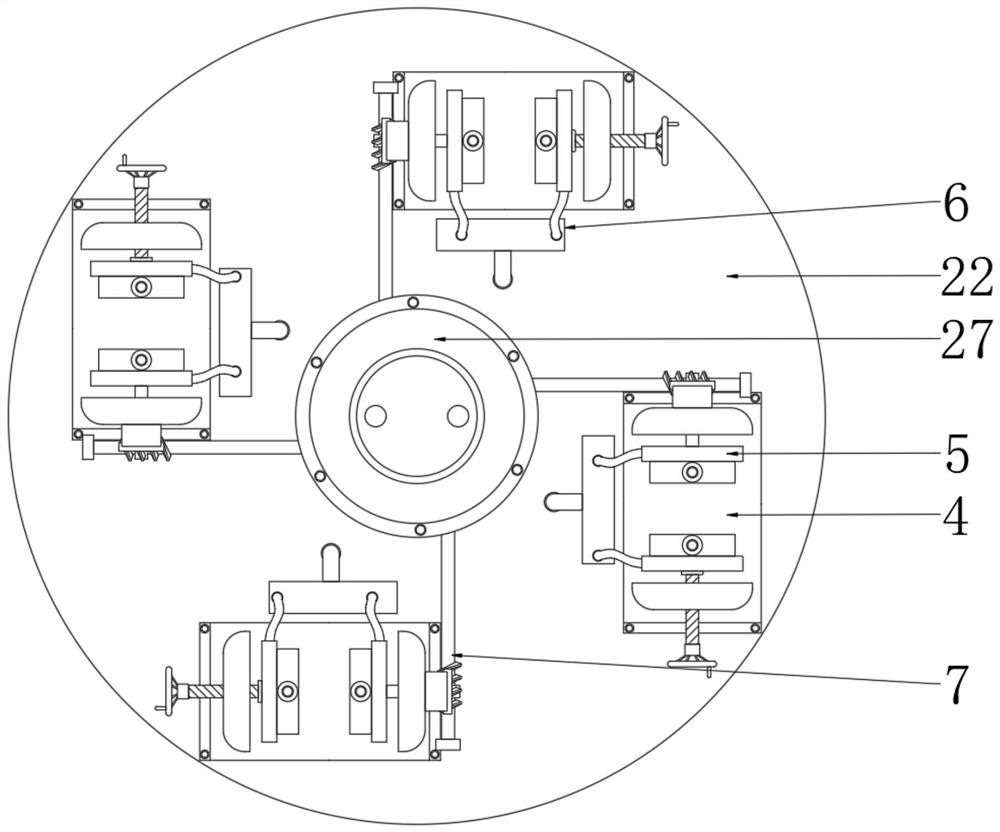

[0031] Embodiment 2: This embodiment is different from the above embodiment, please refer to figure 1 The continuous operation workbench 2 includes a receiving shell 21 fixed at the center of the top of the base 1. The receiving shell 21 is located in front of the mounting frame 8. The receiving shell 21 is cylindrical. The top and bottom of the receiving shell 21 are open. The front of the receiving shell 21 A shell cover (not shown) is provided on the side to facilitate maintenance of the structure in the receiving shell 21. A workbench 22 is arranged above the accepting shell 21. The workbench 22 plays the role of supporting and installing the structure. The bottom of the workbench 22 is from the outside to the outside. An annular flange 1 23 and an annular flange 2 26 are integrally formed inside in turn, the outer wall of the annular flange 2 26 fits the inner wall of the receiving shell 21, and the outer walls of the left and right sides of the annular flange 2 26 are sym...

Embodiment 3

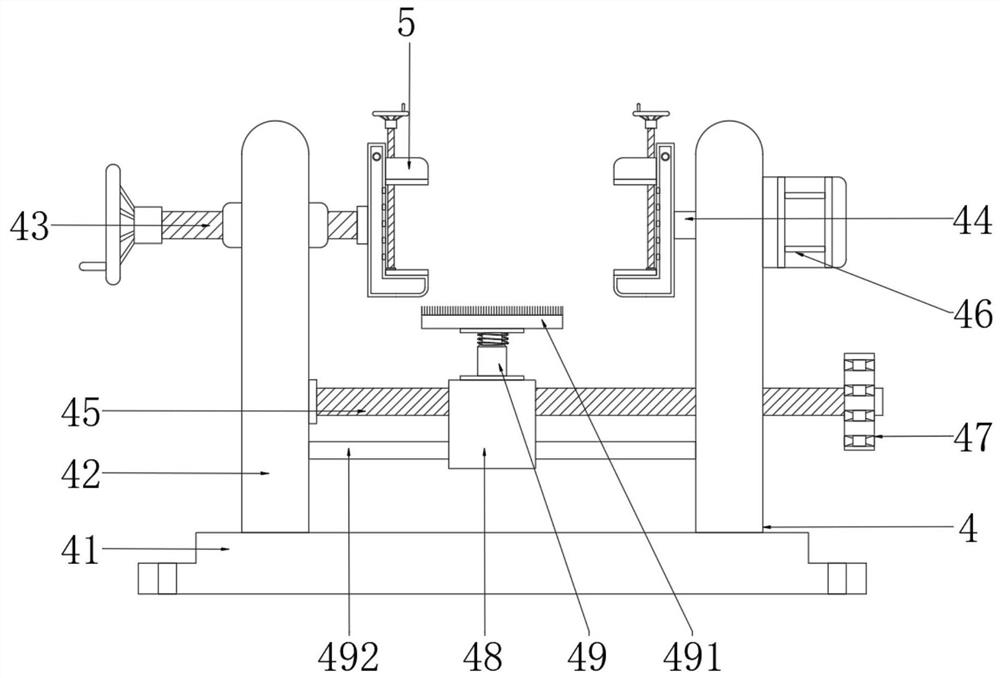

[0032] Embodiment 3: The difference between this embodiment and the above-mentioned embodiment is that please refer to Figure 1-Figure 3 , (Here, the frontmost part accepts the cleaning mechanism 4 as a supporting illustration, and the other three groups of parts accept the cleaning mechanism 4 with the same structure, but the corresponding changes in position will not be described in detail here) Four The parts receiving and cleaning mechanism 4 is arranged in an annular array on the top of the workbench 22. The parts receiving and cleaning mechanism 4 includes a fixed plate 41 fixed on the top of the workbench 22. The fixed plate 41 can be fixed on the workbench 22 by means of screws or bolts. The top, the left and right sides of the top of the fixed plate 41 are fixedly provided with a support plate 42, the support plate 42 plays the role of support and installation structure, the top left and right threads of the left support plate 42 are provided with an adjusting screw 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com