Shaft-built-in rotary charging device

A discharge device, built-in technology, applied in the field of built-in shaft rotary discharge device, can solve problems such as prone to misoperation, increase production cost, reduce work efficiency, etc., to achieve less misoperation, high work efficiency, improved The effect of work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

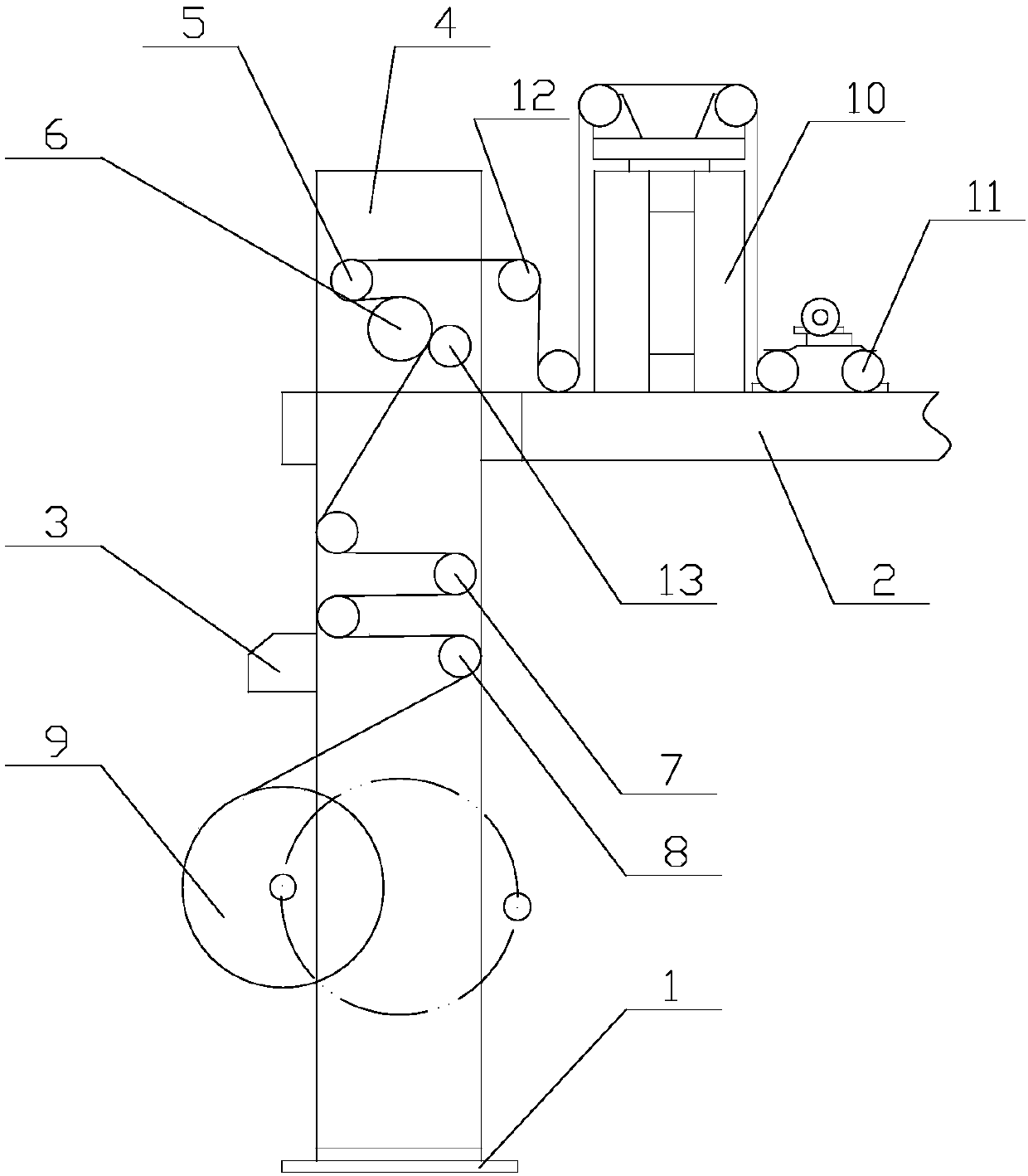

[0013] The present invention will be further described now in conjunction with accompanying drawing. These drawings are simplified schematic diagrams only to illustrate the basic structure of the present invention in a schematic way, so they only show the components relevant to the present invention.

[0014] Such as figure 1 The shown built-in shaft rotary discharge device has a frame 1, the upper end of the frame 1 is provided with a support 2, the middle part is provided with a cutting device 3, and the top of the frame 1 is equipped with a traction upper wall panel 4;

[0015] A pendulum roller device 5 and a discharge traction device 6 are installed on the traction upper wallboard 4, a second pendulum roller device 7 and a guide roller 8 are arranged on the upper side of the frame 1, and a discharge roller 8 is provided at the middle position of the frame 1. Material device 9;

[0016] A deviation correcting device 10 is installed on the support 2, a tension sensing ro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com