Patents

Literature

136results about How to "Less prone to misuse" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Multiparty call display controlling method, device and mobile terminal

ActiveCN103067585AEasy to operateImprove experienceCalling susbscriber number recording/indicationThird partyCommunication interface

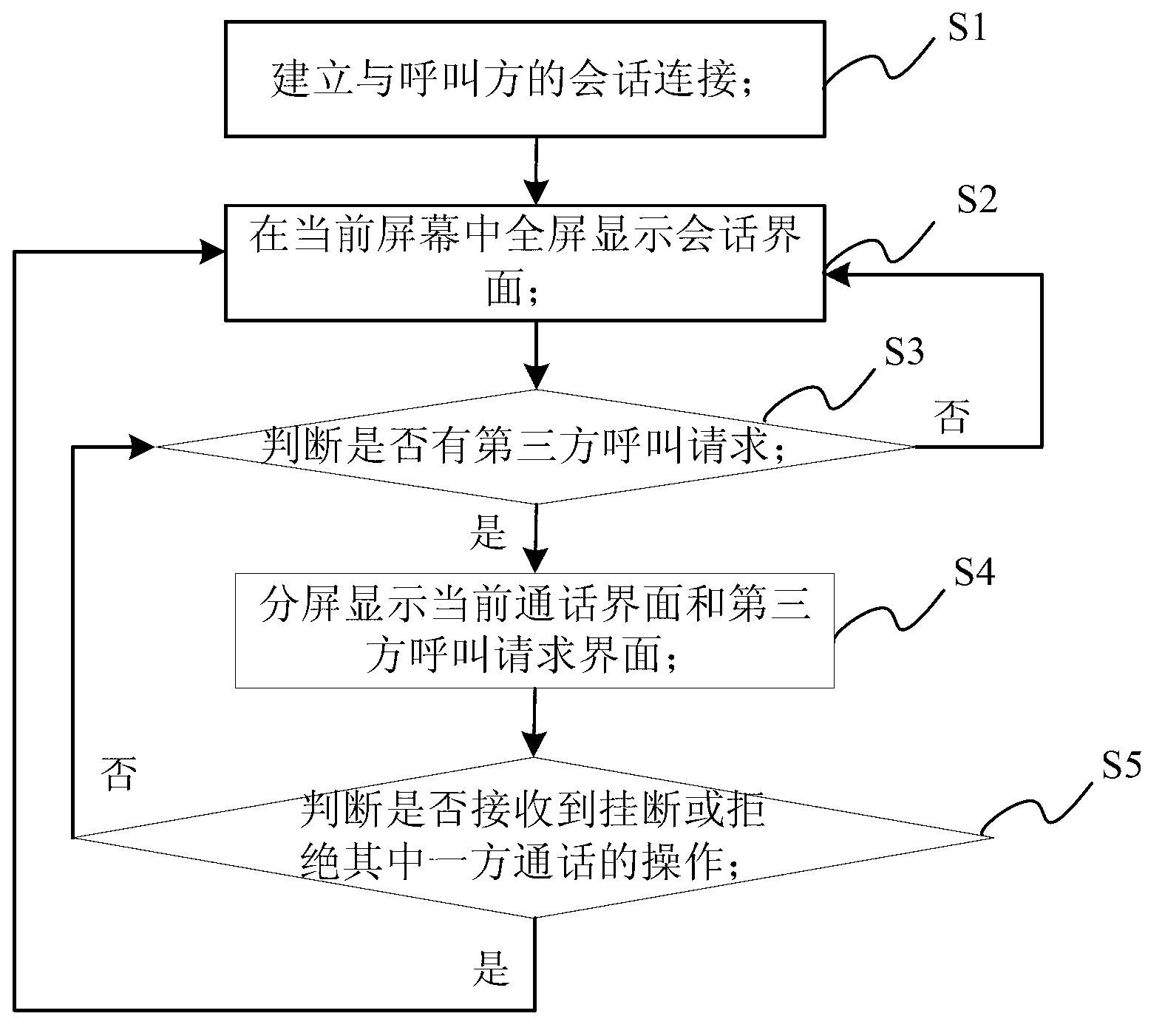

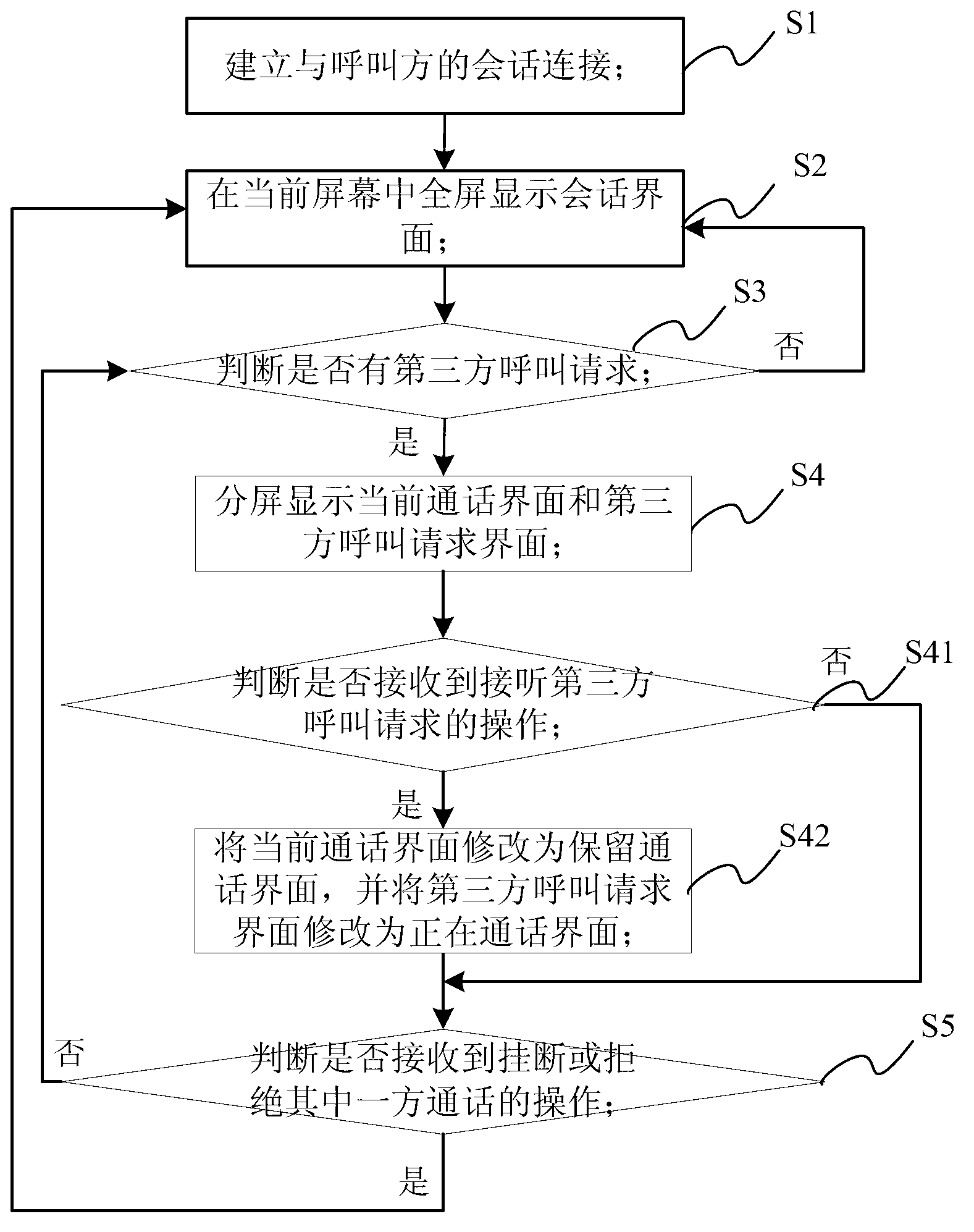

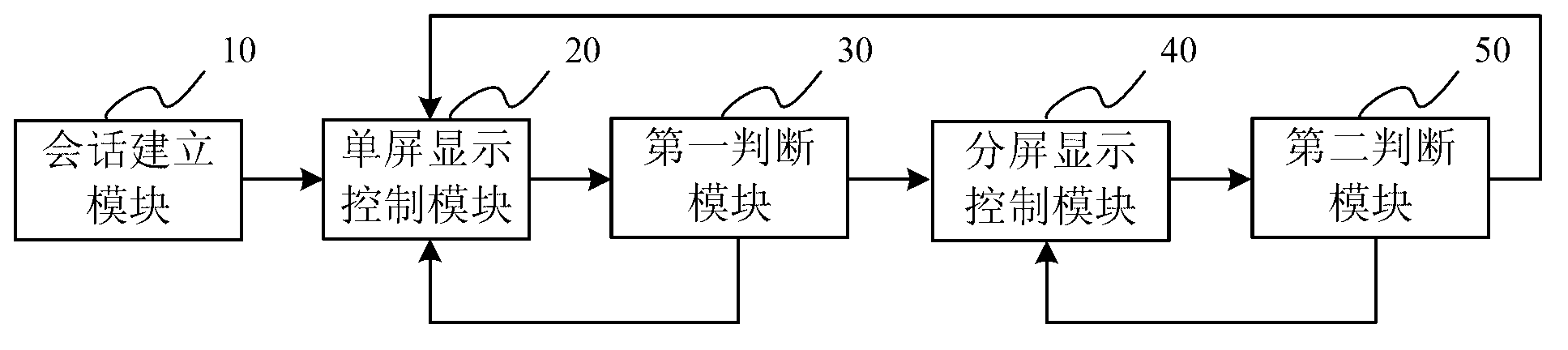

The invention relates to a multiparty call display controlling method, a device and a mobile terminal. The method includes the following steps: (A) establishing conversation connection with calling parties; (B) displaying a conversation interface on a full present screen, then carrying out a step C; (C) judging whether the device has a call request from a third party or not, if yes, carrying out a step D, or, carrying out the step B; (D) diving the present screen into two parts to respectively display an communication interface with conversation established and an interface of the call request of the third party, then carrying out a step E; (E) judging whether operation which requires to hang up or refuse communication with one party is received or not, if yes, returning to the step B, and if no, returning to the step D. Through split-screen display, a three-party communication interface is enabled to be attractive and fast, operation by users is convenient, misoperation is not easy to produce, three-party communication can be easily achieved, even three-party video communication can be achieved, and user experience is improved.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

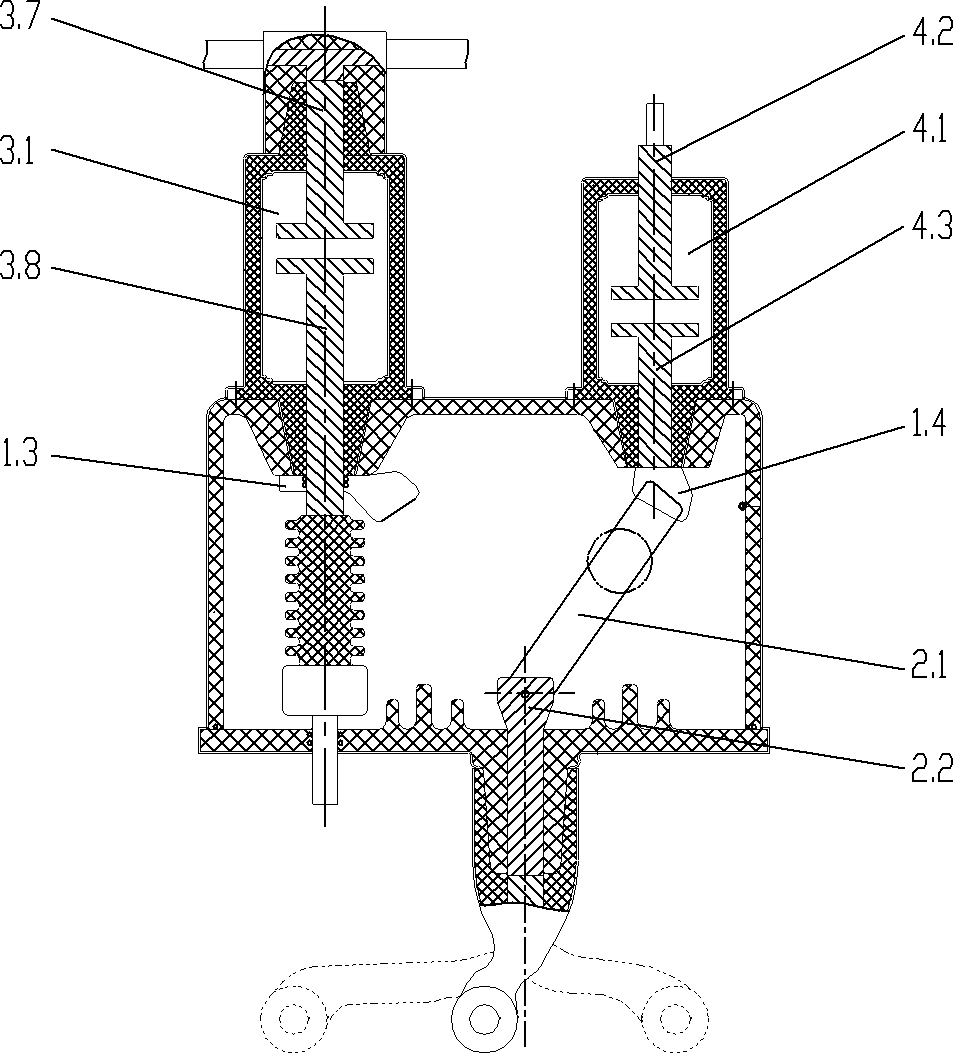

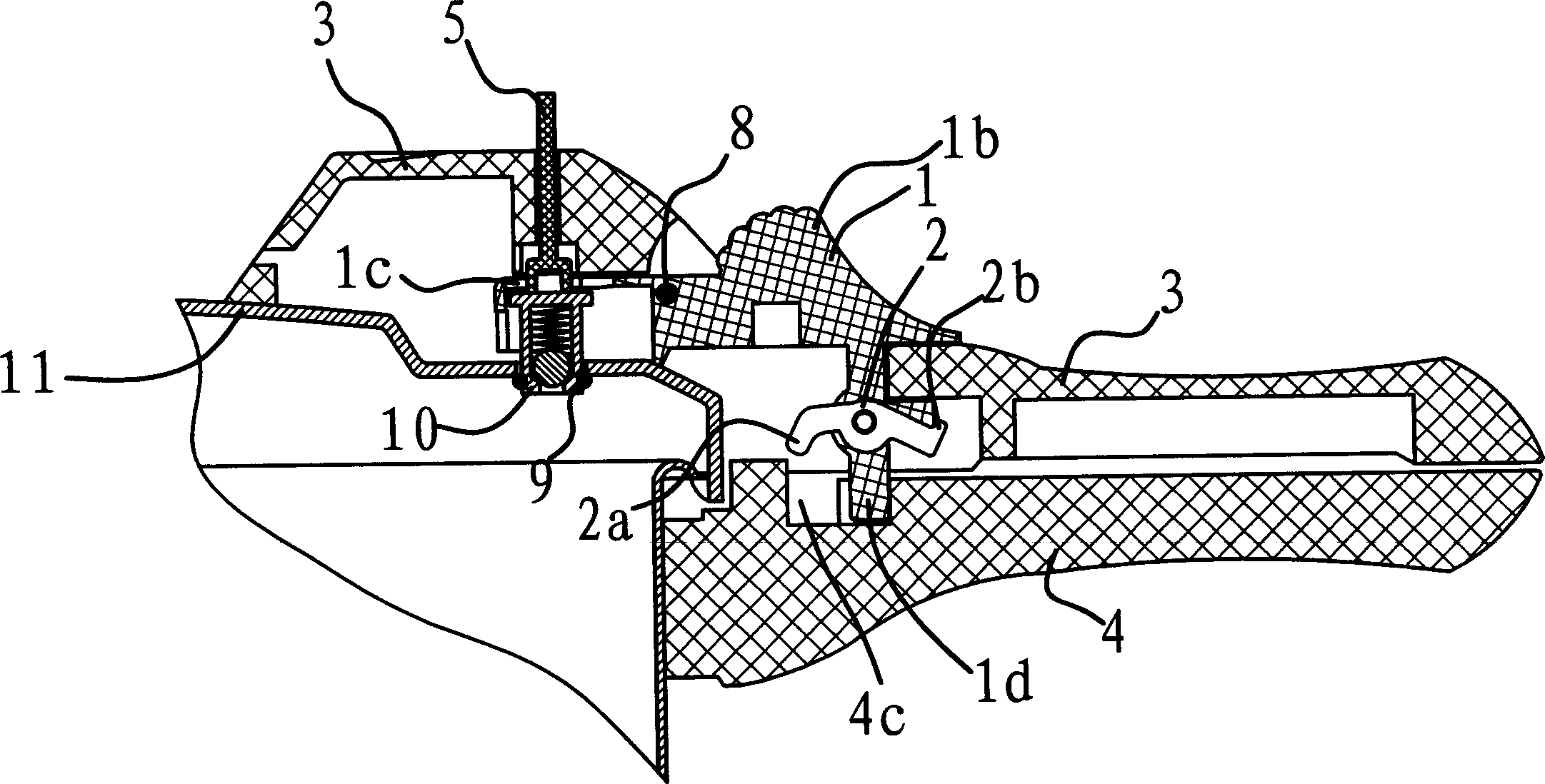

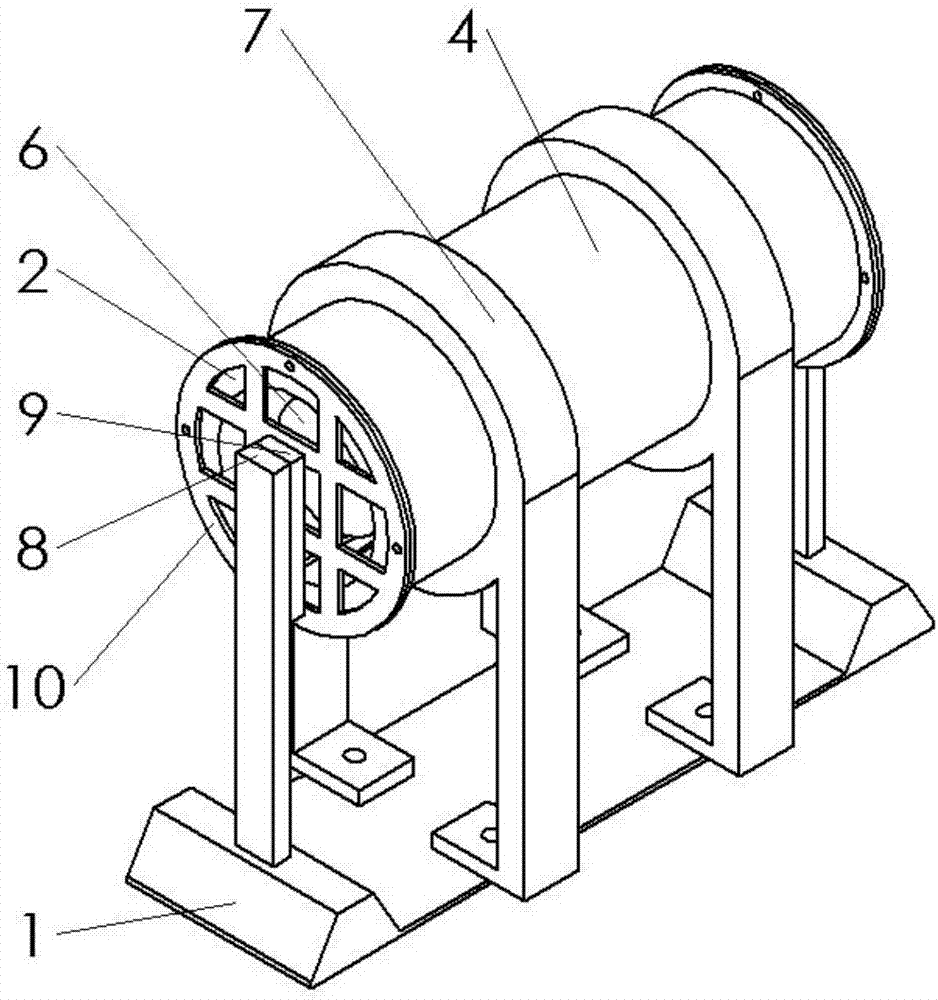

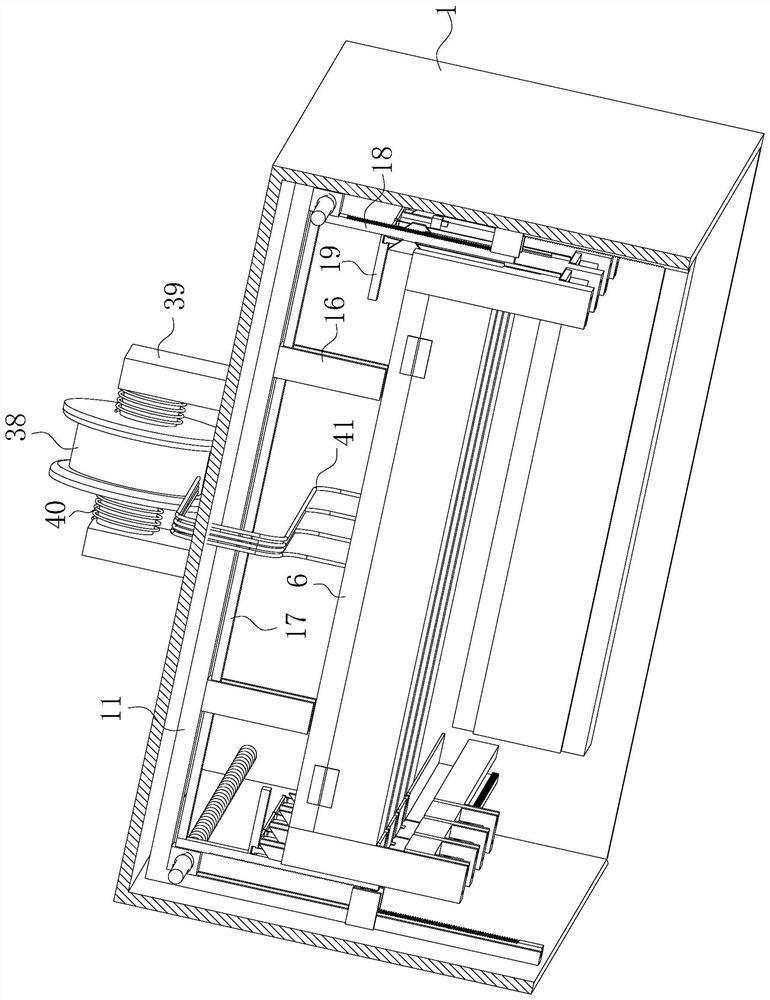

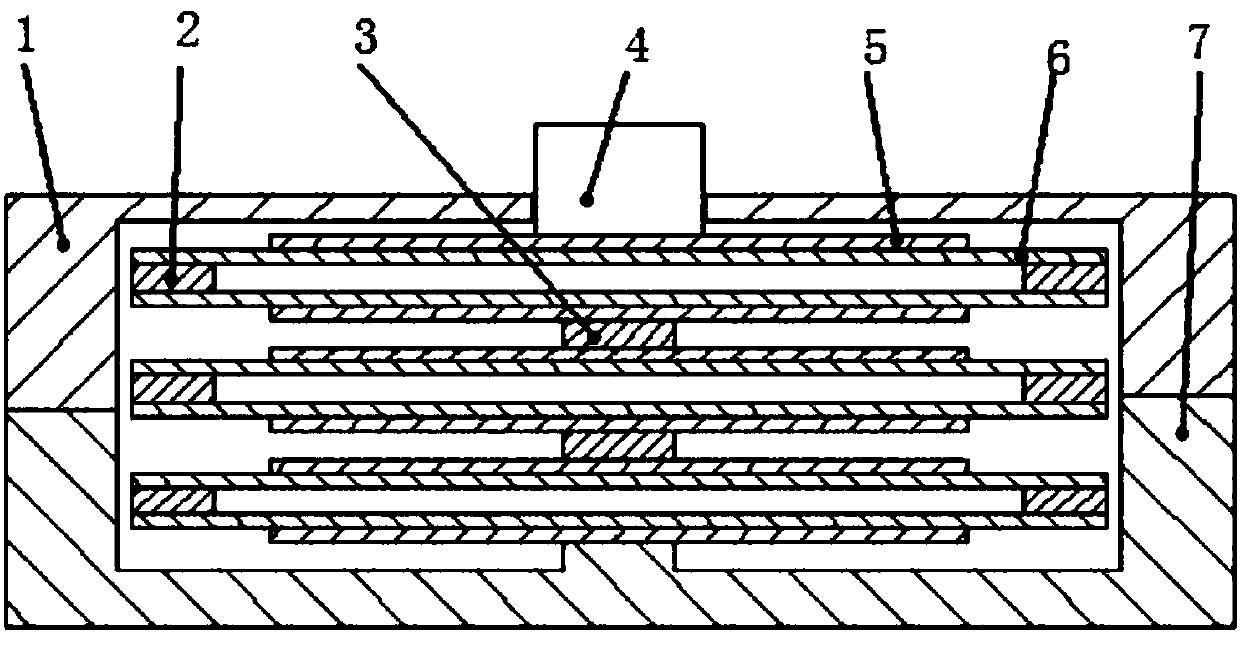

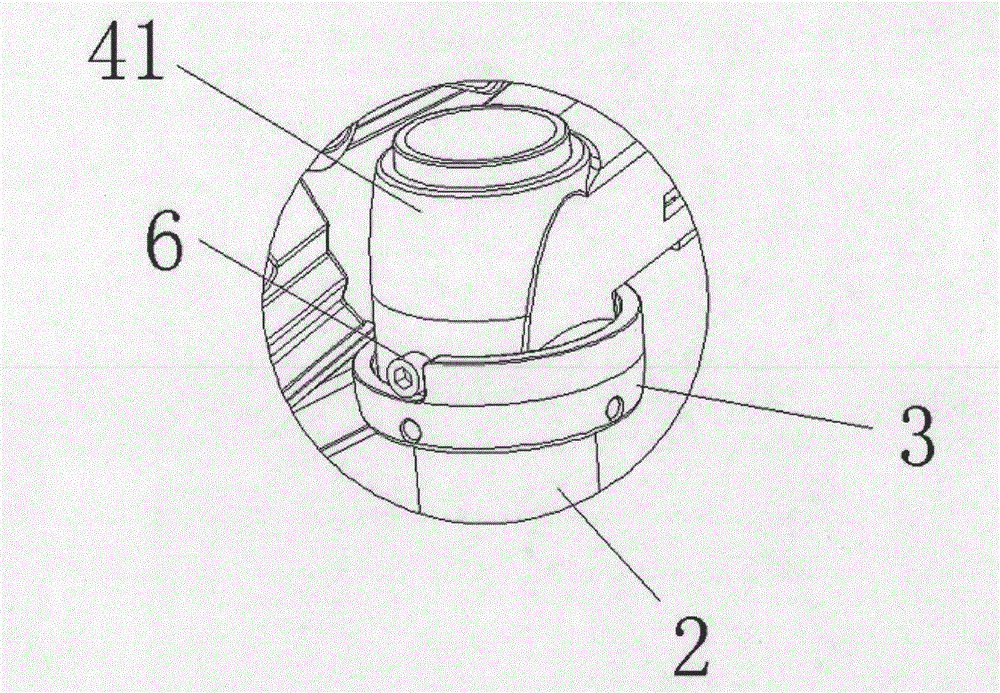

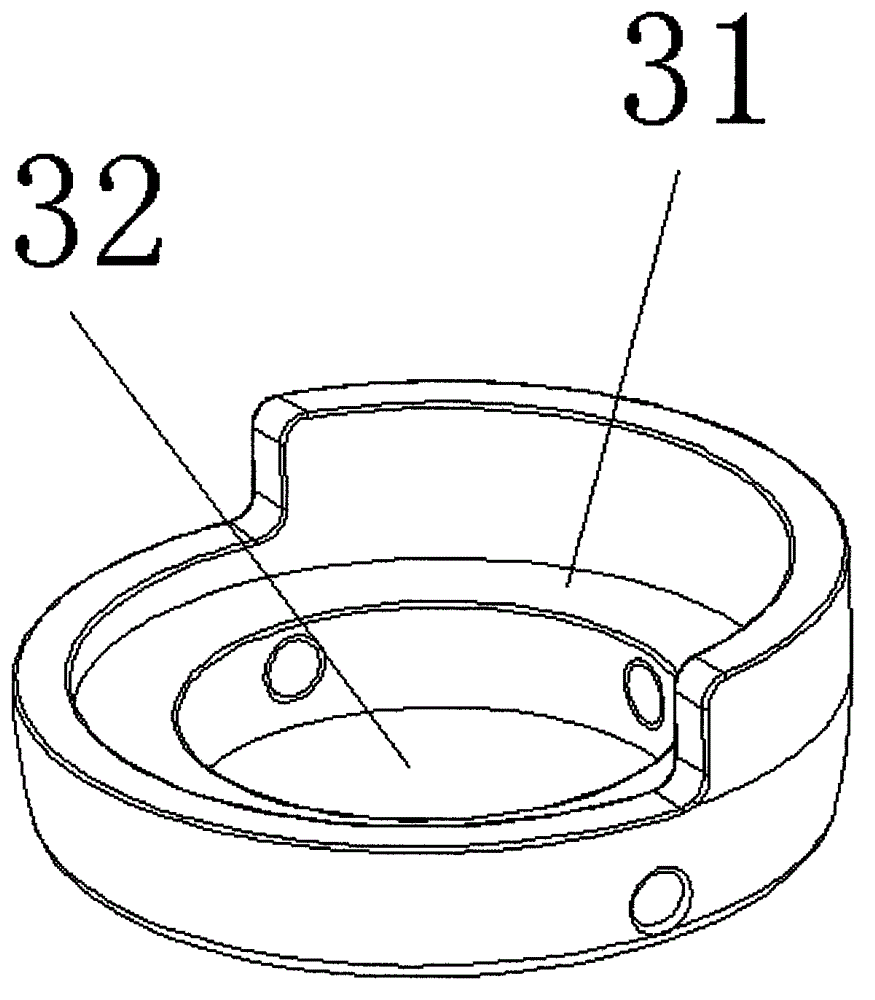

Solid insulation ring main unit

ActiveCN103368096AReduce control precision requirementsGuaranteed to workSwitchgear arrangementsHigh-tension/heavy-dress switchesEngineeringVacuum switch

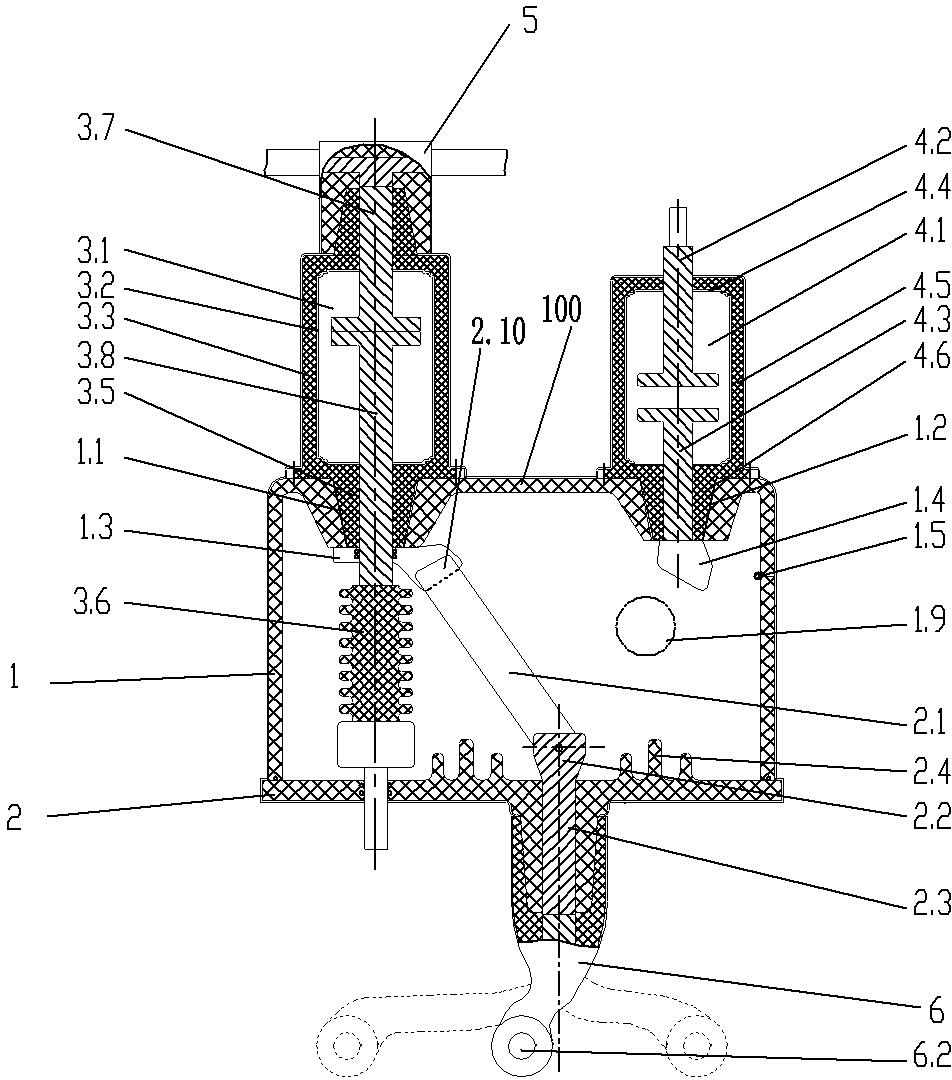

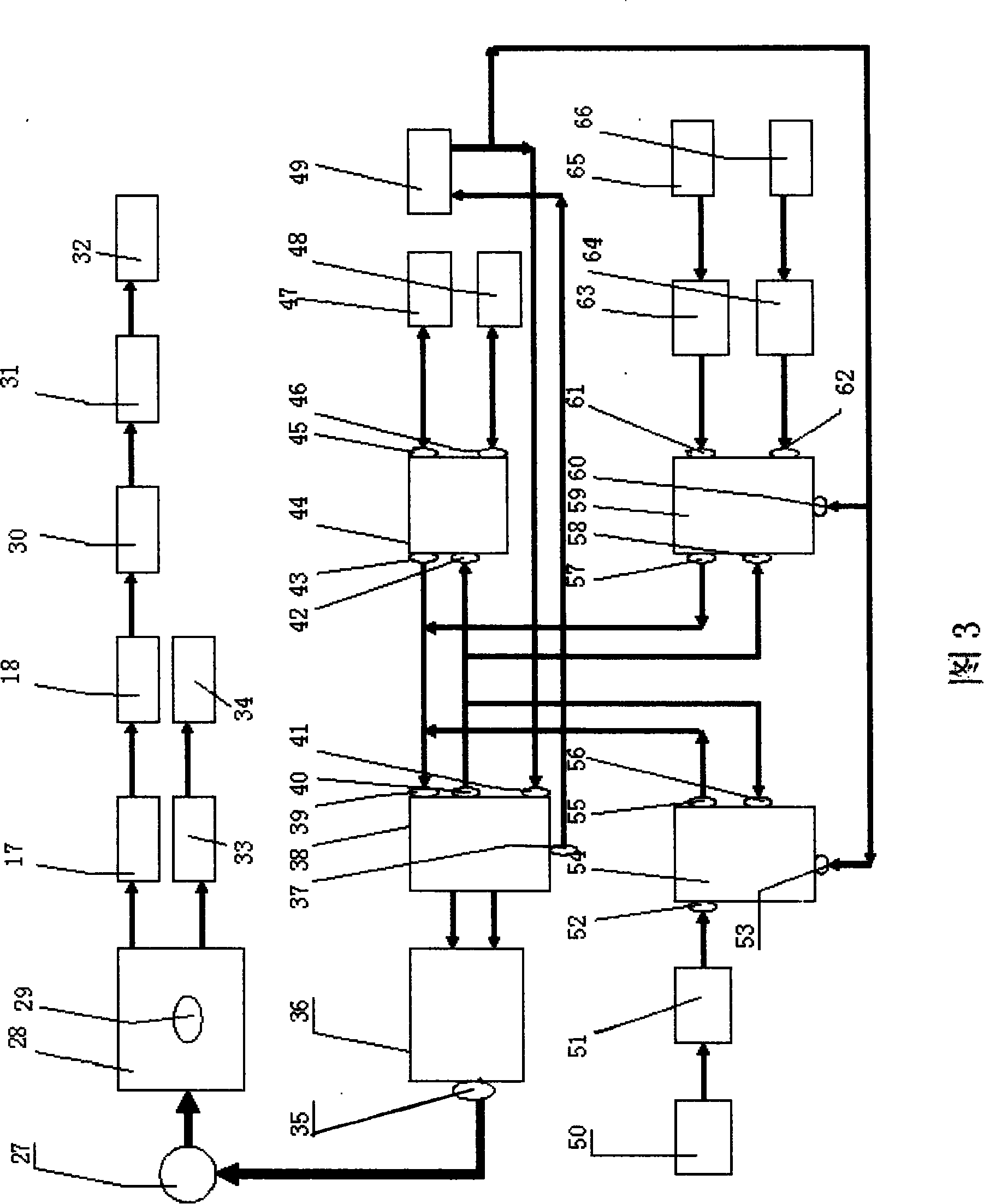

The invention discloses a solid insulation ring main unit, comprising a high-voltage switch unit; the high-voltage switch unit comprises a vacuum arc-extinguishing chamber and an isolation grounding switch device comprising an insulation cavity body; a line outlet end, a grounding end and a line inlet end electrically connected with a conductive rod are arranged on the insulation cavity body; a vacuum switch tube for grounding is fixedly arranged inside or outside the insulation cavity body; the static contact of the vacuum switch tube for grounding is electrically connected with the grounding end while the movable contact is provided with a grounding wiring part; the movable contact of the vacuum switch tube for grounding is in transmission connection with a grounding operative mechanism; an isolation disconnecting link is arranged in the insulation cavity body; one end of the isolation disconnecting link is a hinging end hinged to the line outlet end while the other end is a contact end; and a driving mechanism is connected onto the isolation disconnecting link in a transmission way. The isolation grounding switch is positioned in different work conditions by controlling the swinging of the isolation disconnecting link and the connecting / disconnecting states of the static and movable contacts in the vacuum switch tube.

Owner:STATE GRID CORP OF CHINA +2

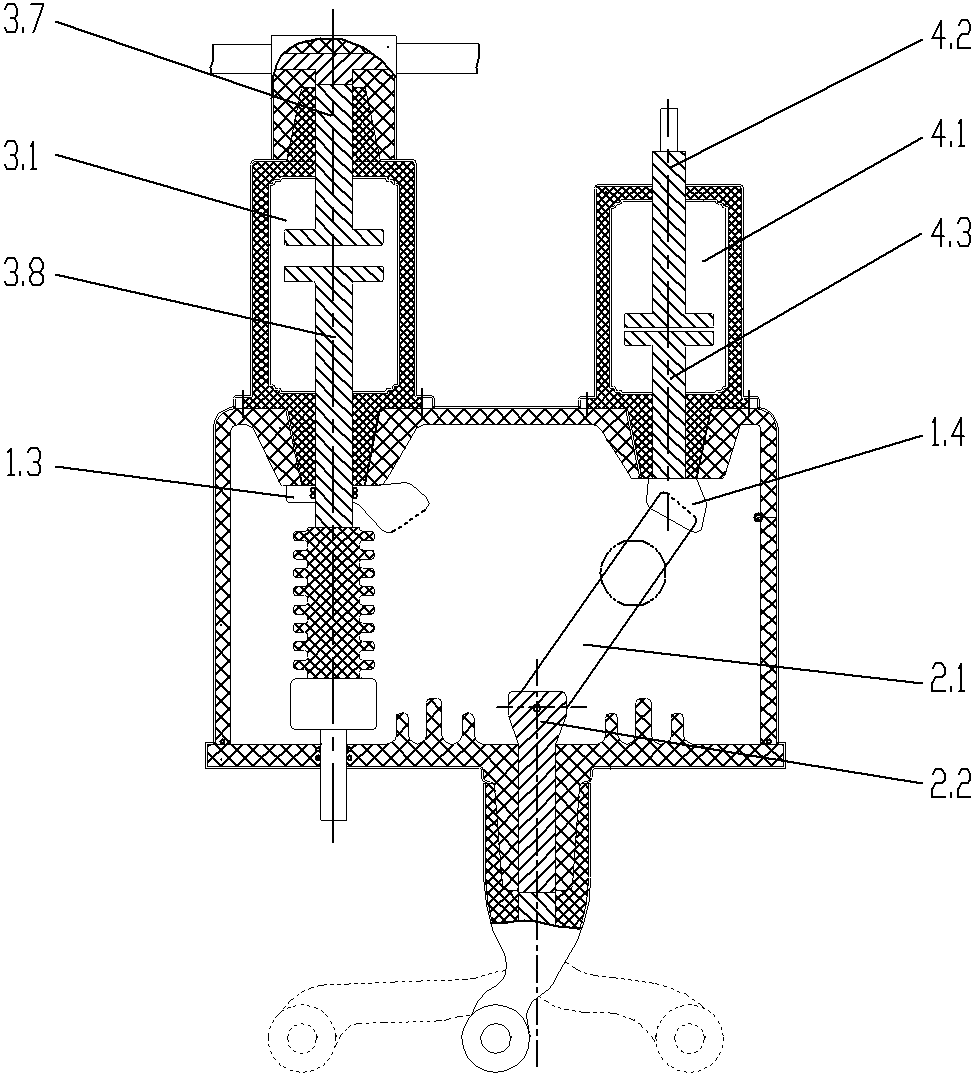

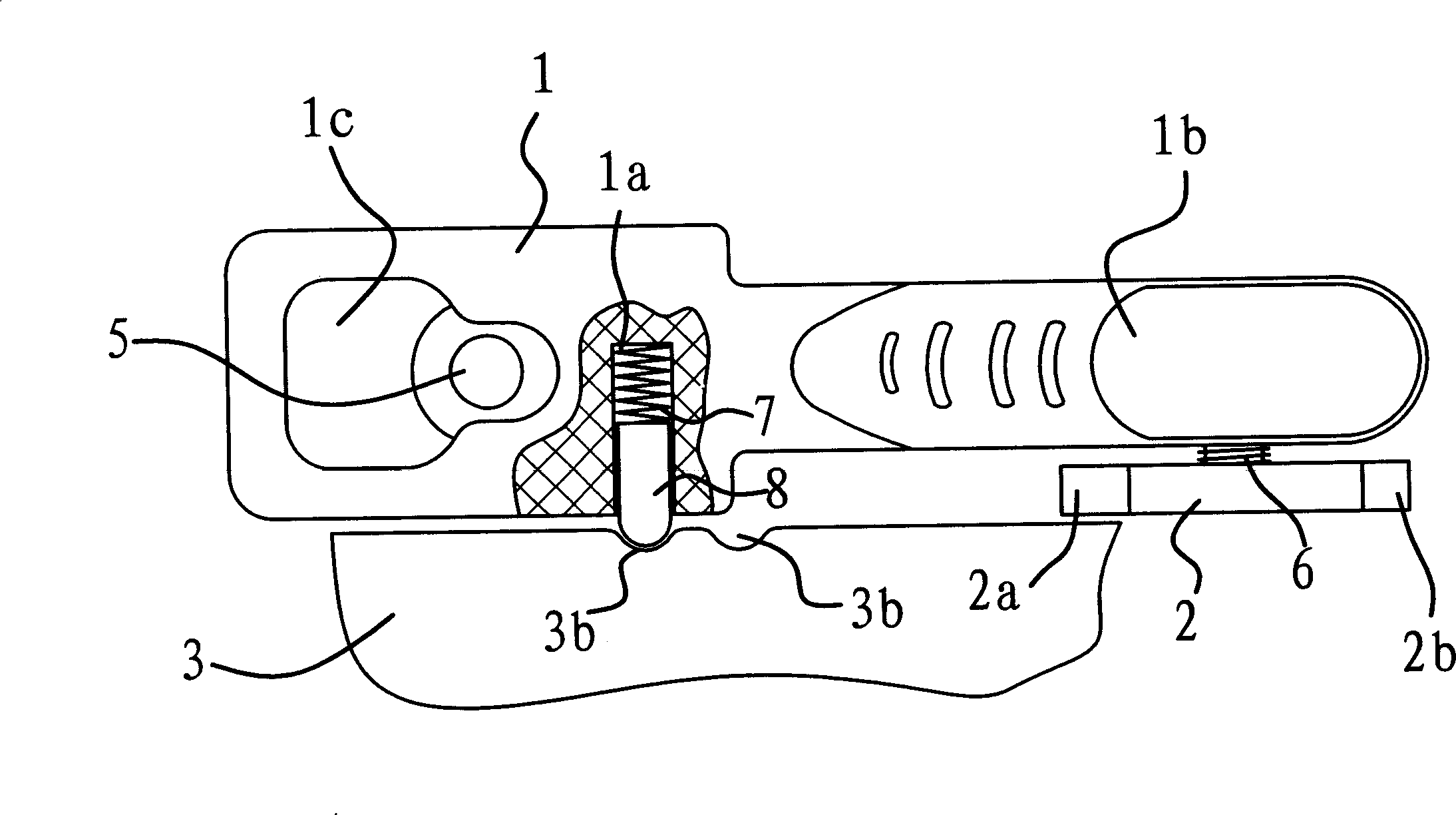

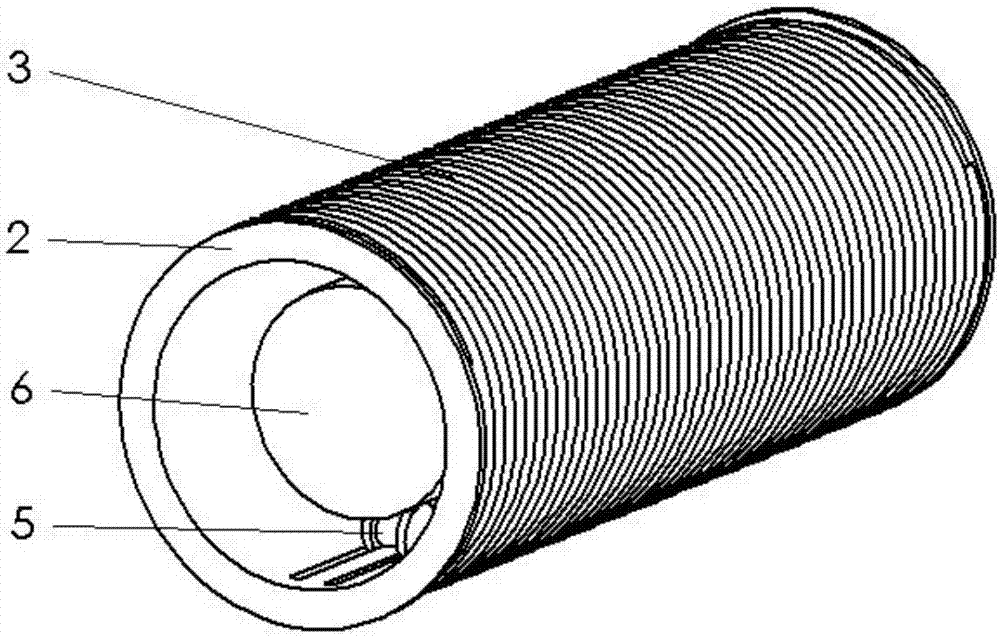

Down-hole instrument high-speed single-core cable transmission device

The invention relates to a downhole instrument high-speed single-core cable transmission device used for well logging of a flowing well and a water injection well, wherein, a high-speed cable telemetry pipe nipple is connected with a releaser through a single-core plug on the upper end and connected with various parameter measurement pipe nipples through a slip ring four-core plug on the lower end; a telemetry pipe nipple circuit and a parameter pipe nipple circuit comprise singlechips which are connected with industrial buses; a telemetry pipe nipple industrial bus and a parameter measurement pipe nipple industrial bus are communicated with each other through a signal core 2 and a signal core 3 of the slip ring four-core plug; each singlechip comprises 8 address bits, 16 data bits and 255 test channels, controls a data output port to transmit serial data and a data input port to receive the serial data, and controls transmission and receipt of industrial bus data; after address comparison and coding of the received data and controlled transmission and receipt of the industrial bus data, the data is transmitted to the ground through a single-core cable; transmission rate of the cable reaches 20 K, and transmission rate of a downhole instrument reaches 40K, thereby well-logging aging is greatly improved.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

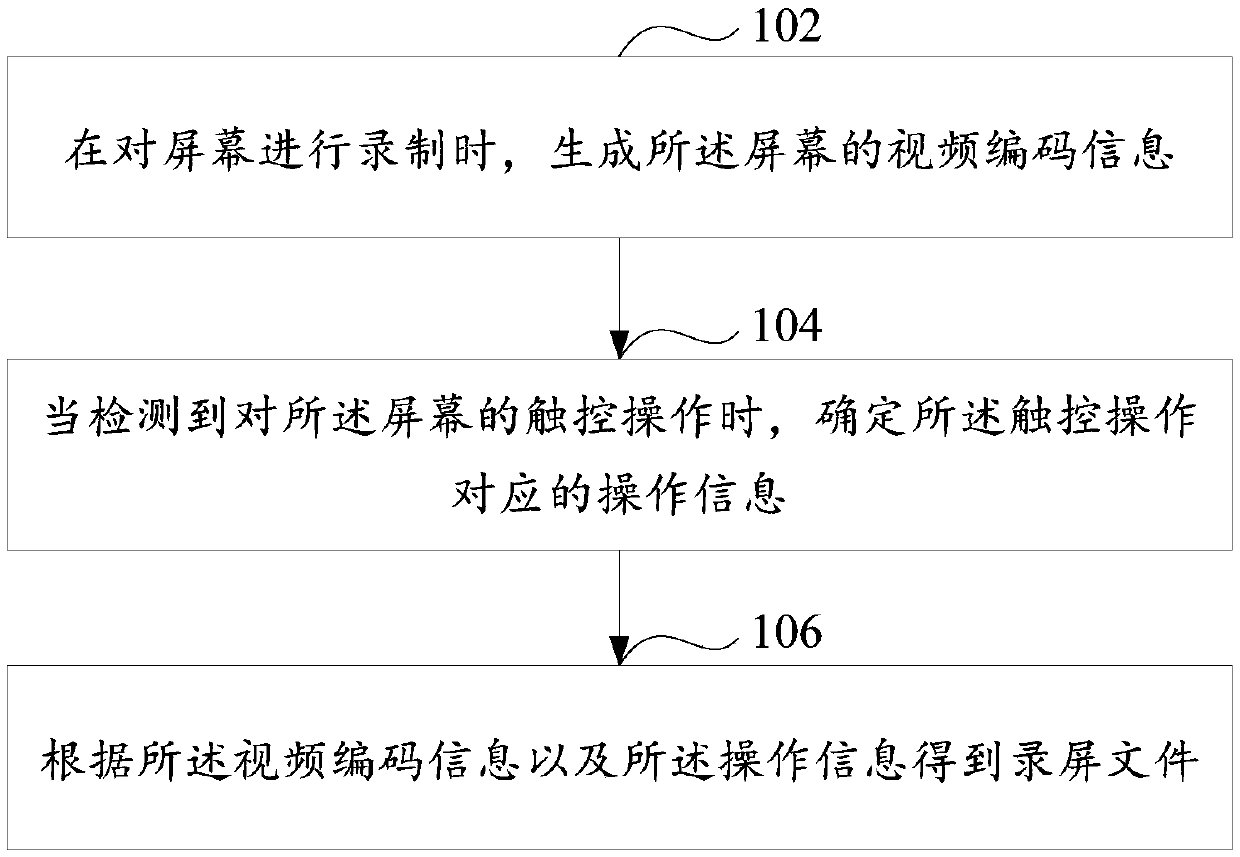

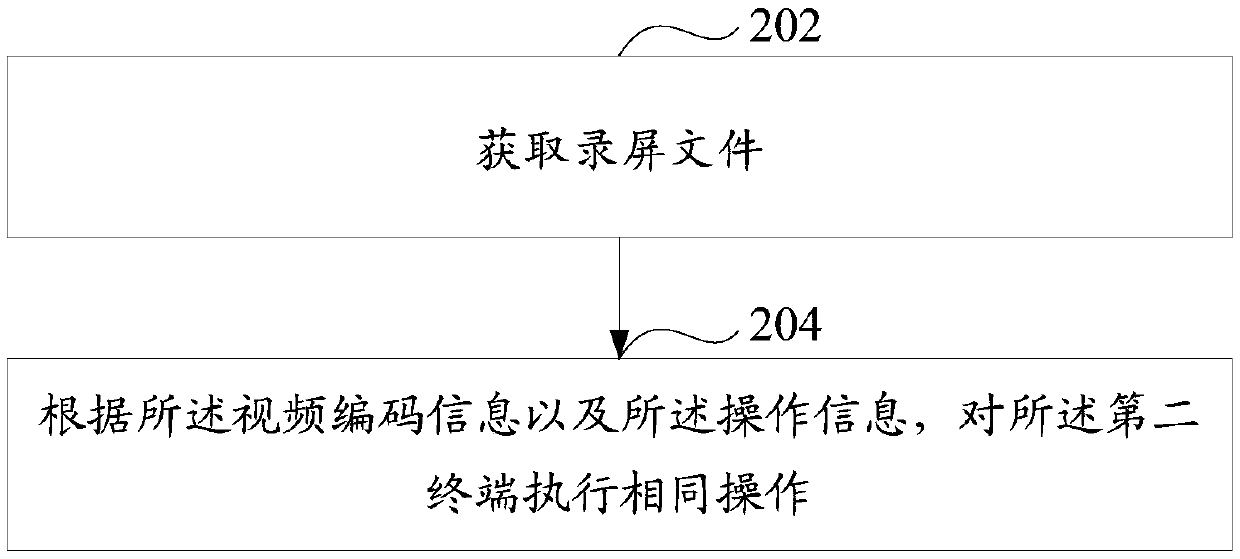

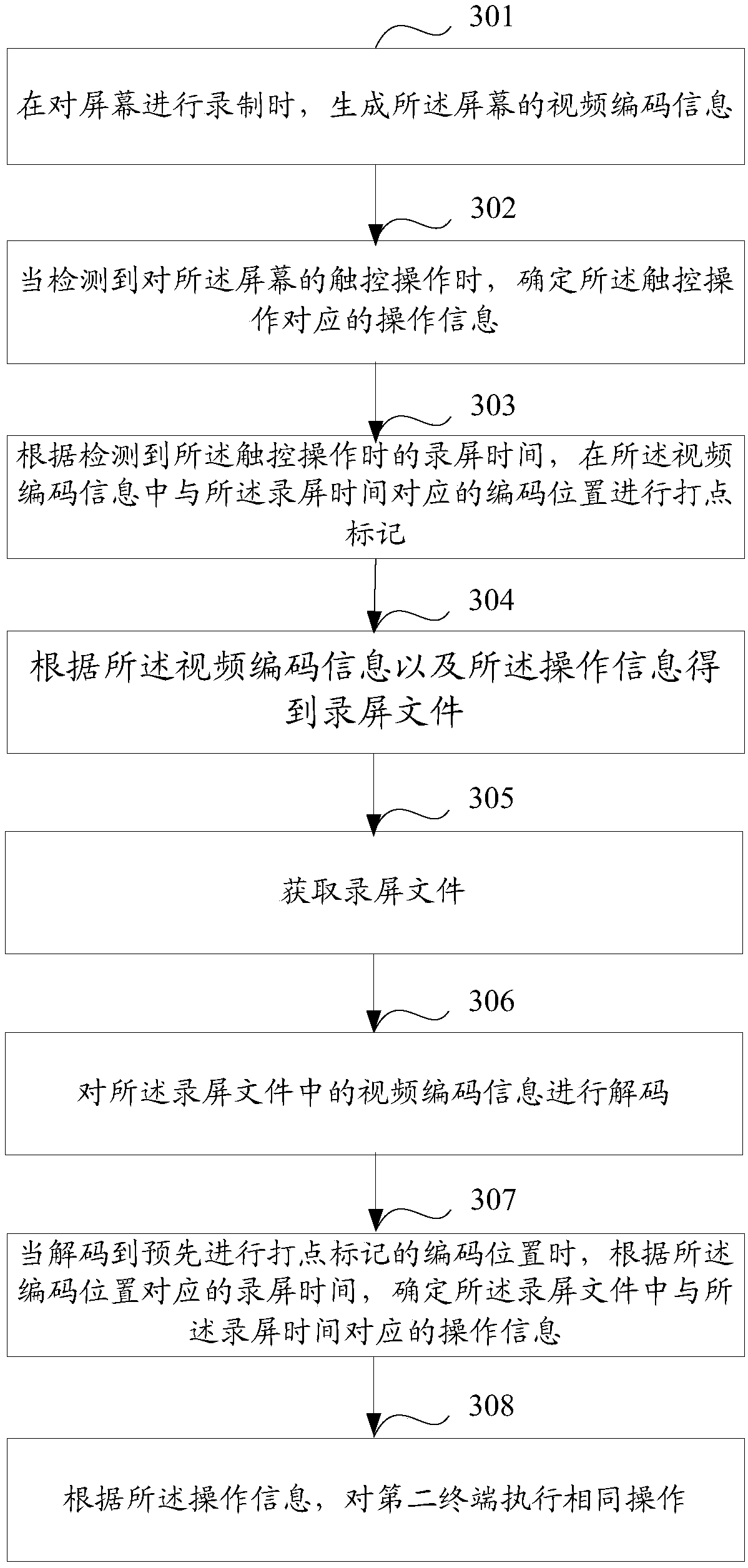

Screen recording, screen-based reproduction method, terminal

InactiveCN109521935AReduce stepsImprove experienceDigital video signal modificationSelective content distributionVideo encodingComputer terminal

The invention discloses a recording screen, a reproduction method based on the recording screen and a terminal. The recording screen method comprises the following steps: when recording the screen, generating the video coding information of the screen; Determining operation information corresponding to the touch operation when a touch operation to the screen is detected; According to the video encoding information and operation information, acquiring a recording screen file, and the recording screen file contains the video encoding information and the operation information. At that time of record the screen, while generating video encoded information, recording the operation information corresponding to the touch operation received during the recording process, obtaining a recording screenfile containing video encoding information and operation information, Thus, when the second terminal acquires the screen recording file and performs scene reproduction, intelligently recognizing theoperation information contained in the screen recording file, and automatically performing the scene reproduction according to the operation information, and the user does not need to repeatedly viewthe screen recording file and perform manual reproduction, so that the user operation can be reduced, and the user experience can be improved.

Owner:VIVO MOBILE COMM CO LTD

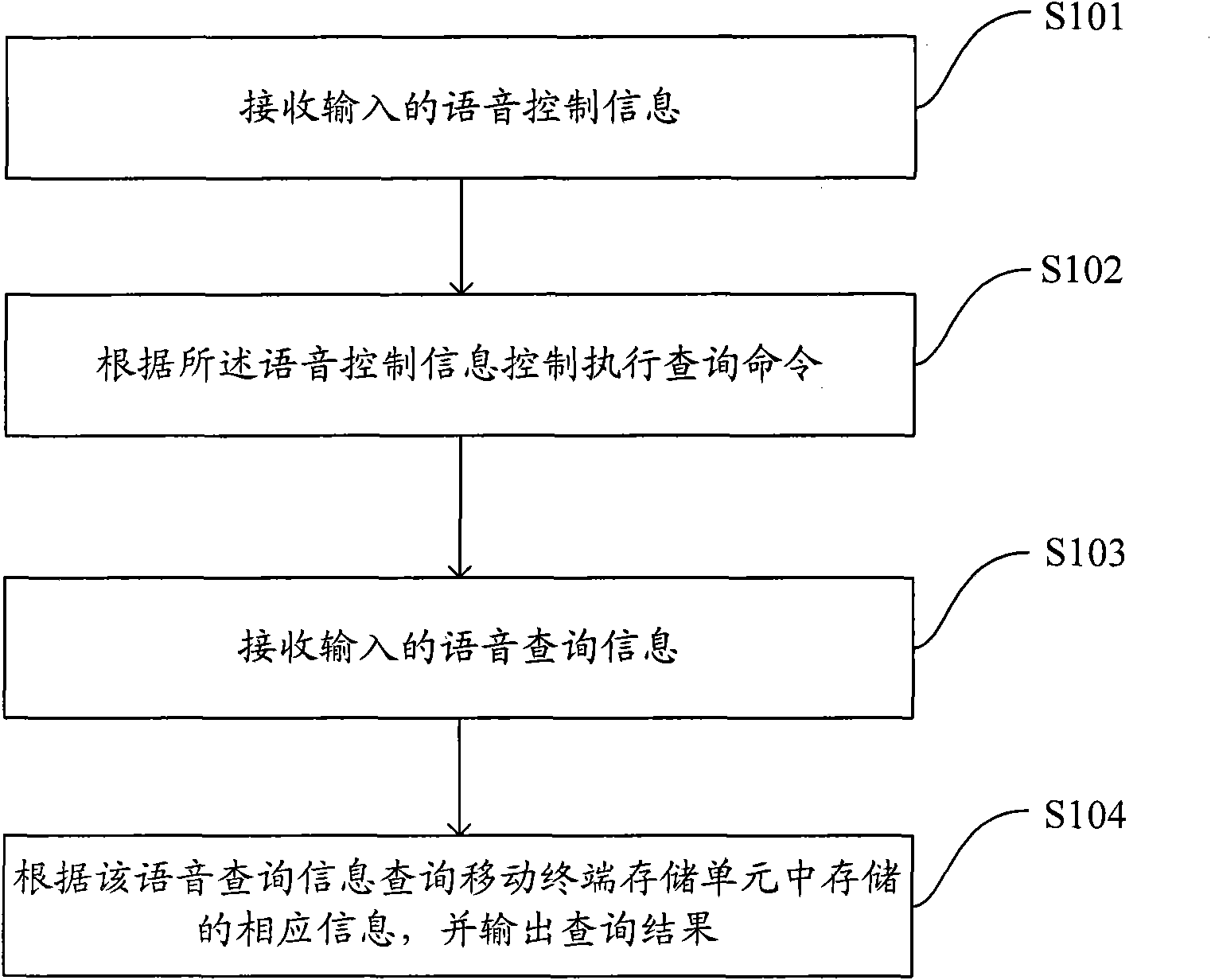

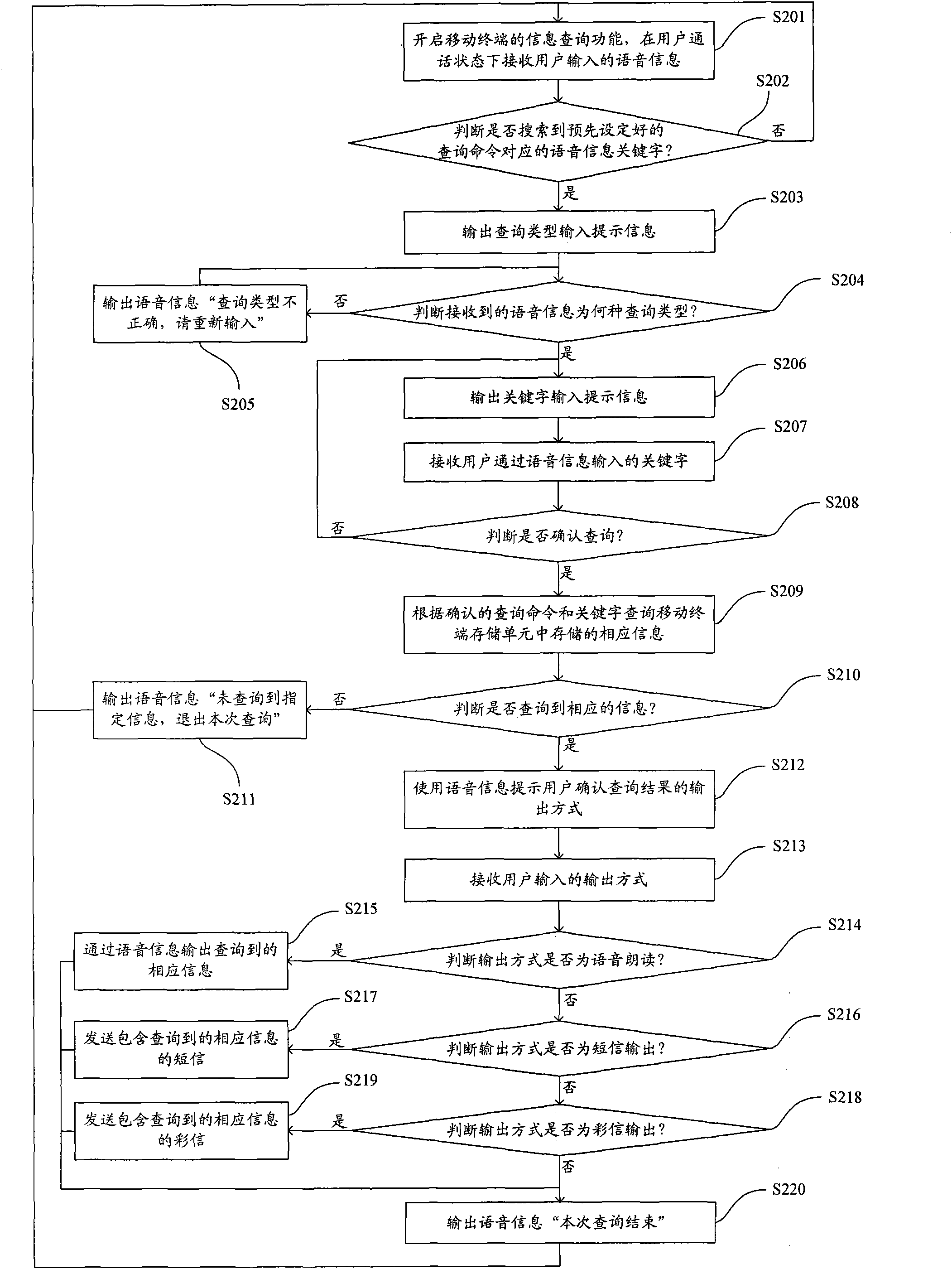

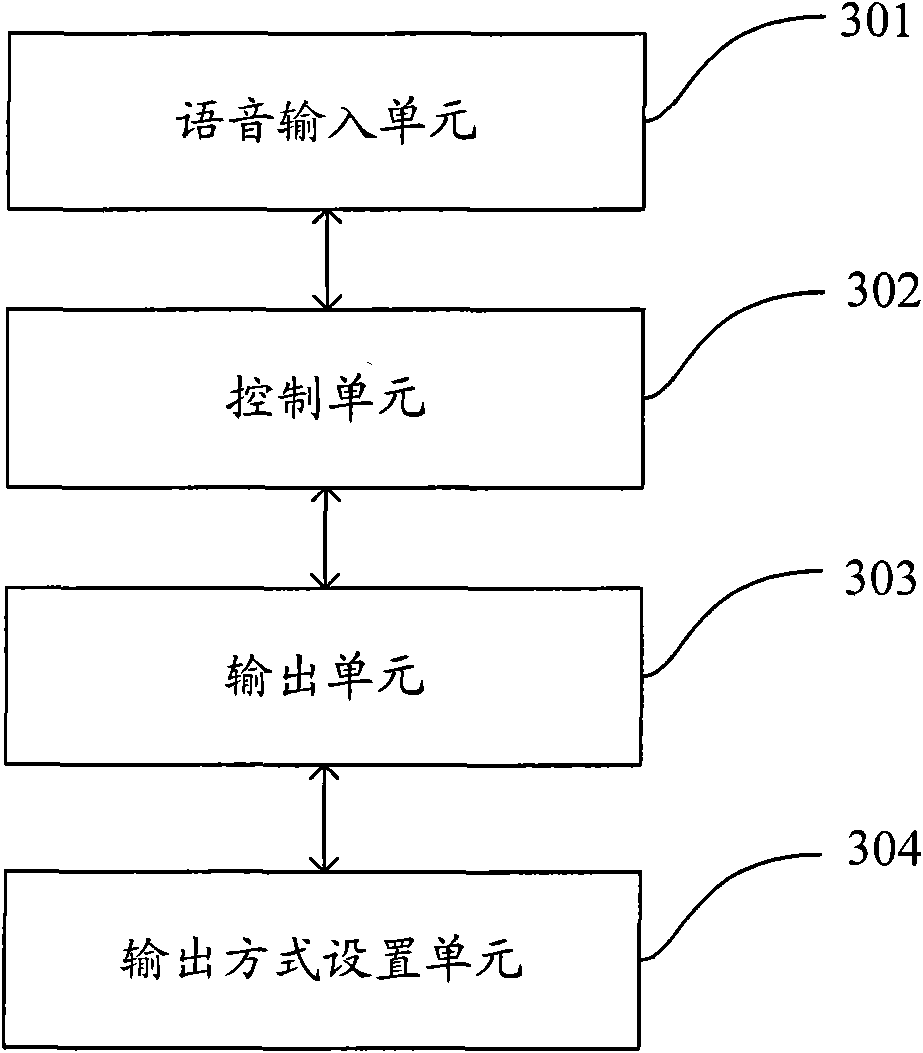

Method and device for querying information in call process and mobile terminal

ActiveCN102111483AEasy to find informationNot easy to misuseSubstation equipmentSpeech soundComputer science

Owner:BYD CO LTD

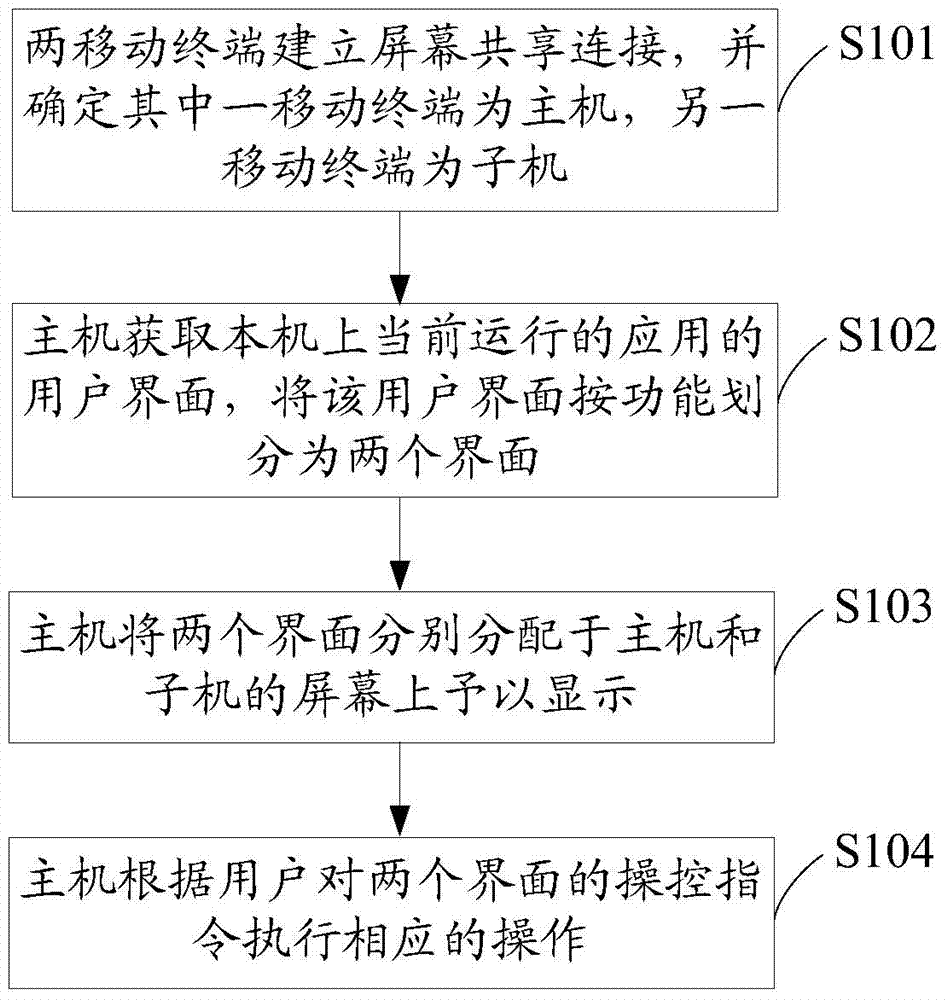

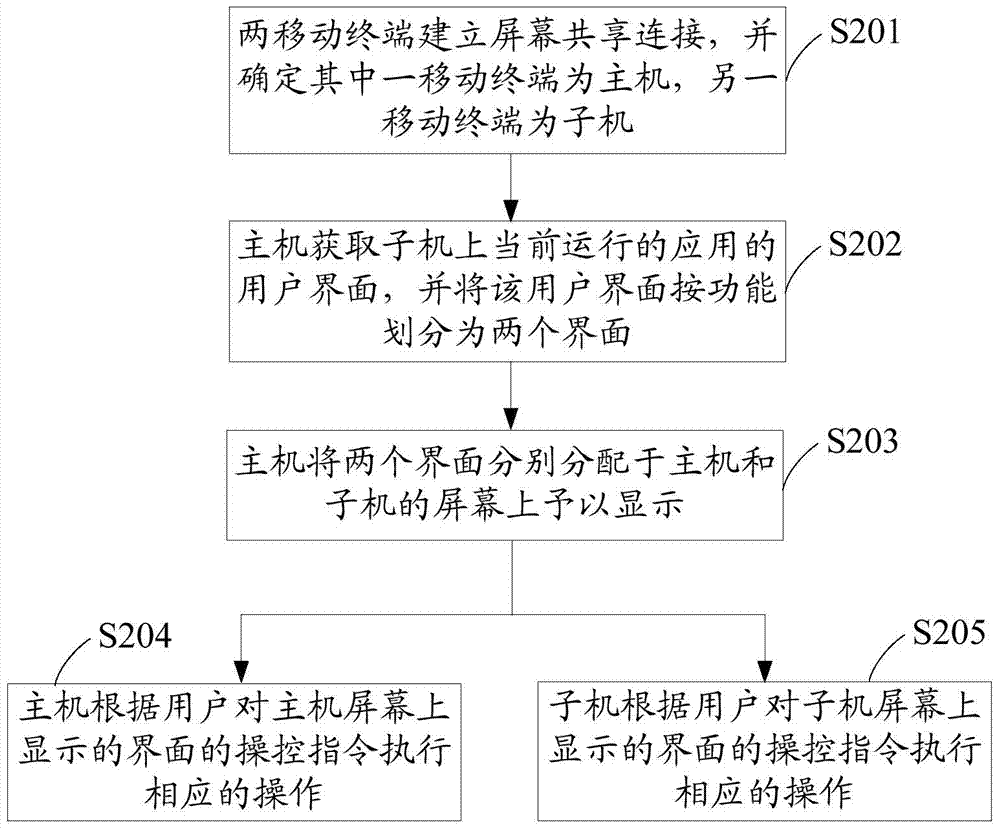

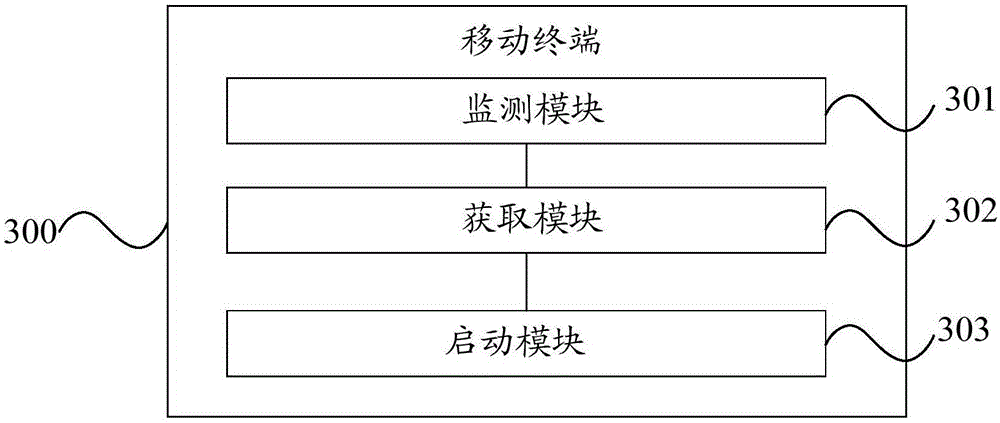

Screen sharing method, system and mobile terminal

InactiveCN104333650AImprove experienceLess prone to misuseSubstation equipmentScreen sharingComputer terminal

The invention discloses a screen sharing method, a system and a mobile terminal. The screen sharing method comprises the following steps that a screen sharing connection is established between two mobile terminals, wherein one mobile terminal is a host and the other mobile terminal is a sub-machine; the host divides a user interface of a current running application on the host or the sub-machine into two interfaces according to functions; and the host respectively distributes the two interfaces to screens of the host and the sub-machine to display. According to the screen sharing method, the system and the mobile terminal, the user interface, especially an operation interface, such as an input box and a virtual keyboard therein, is expanded, so that a user edits or inputs a content more conveniently and quickly through the expanded operation interface, the wrong operation is unlikely to generate, the accuracy for operation is higher, and the user experience is improved.

Owner:NUBIA TECHNOLOGY CO LTD

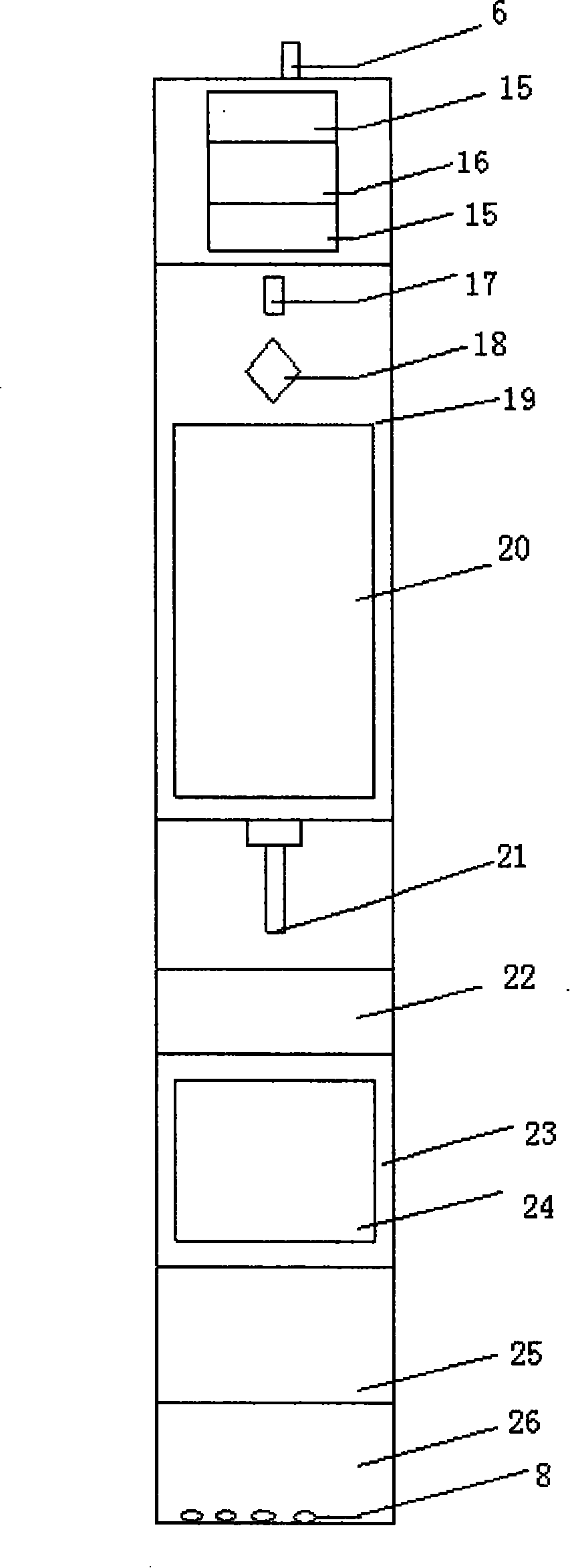

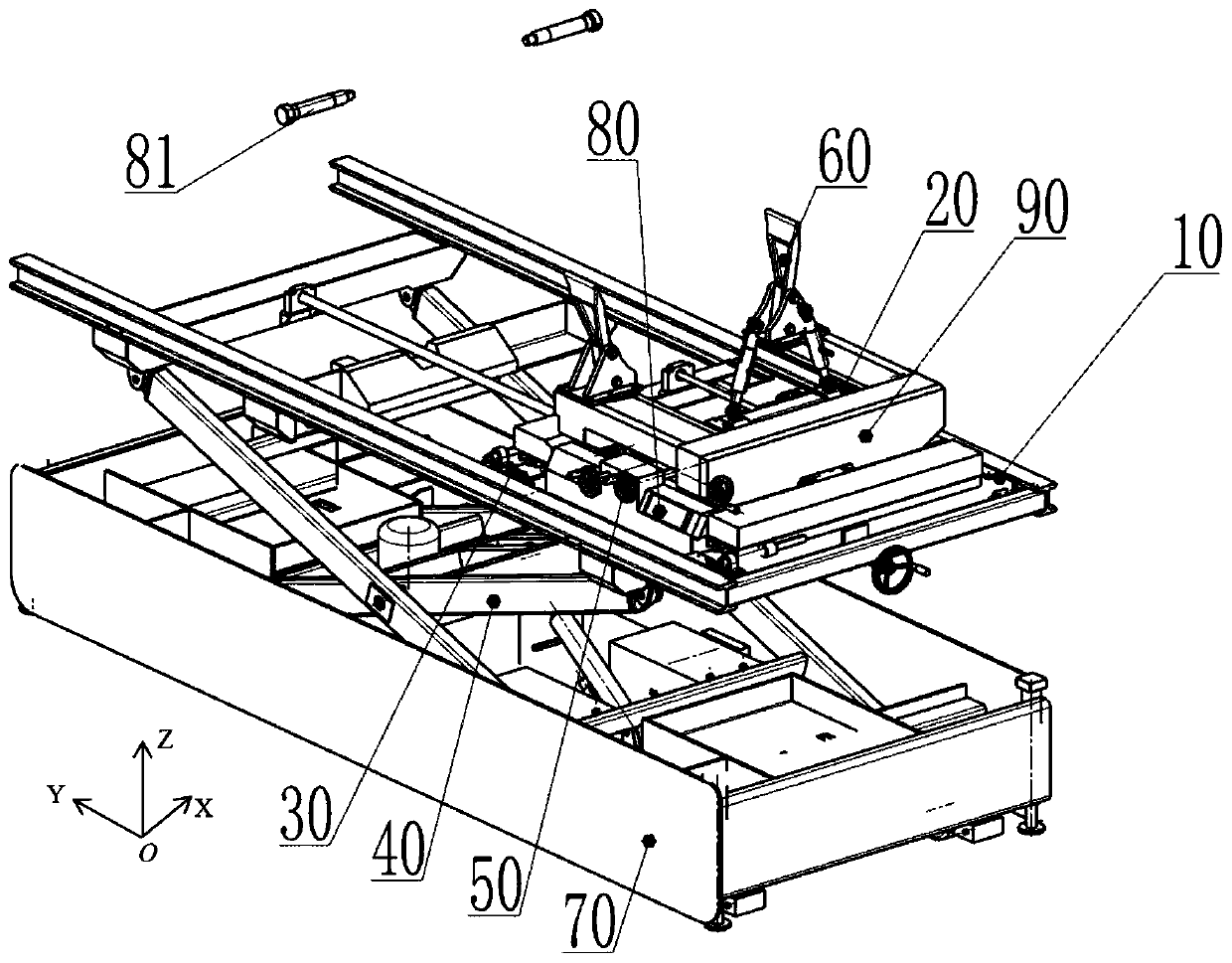

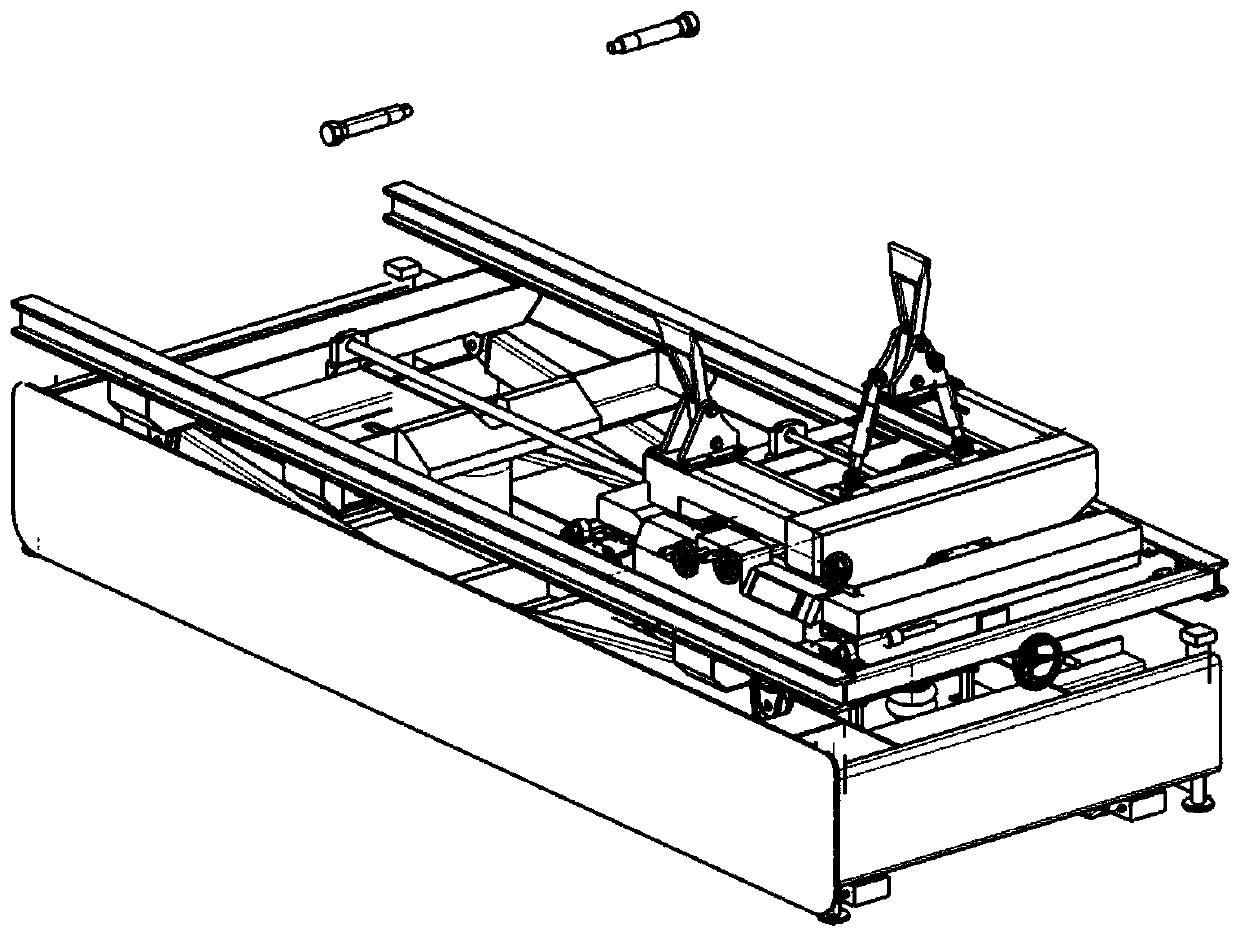

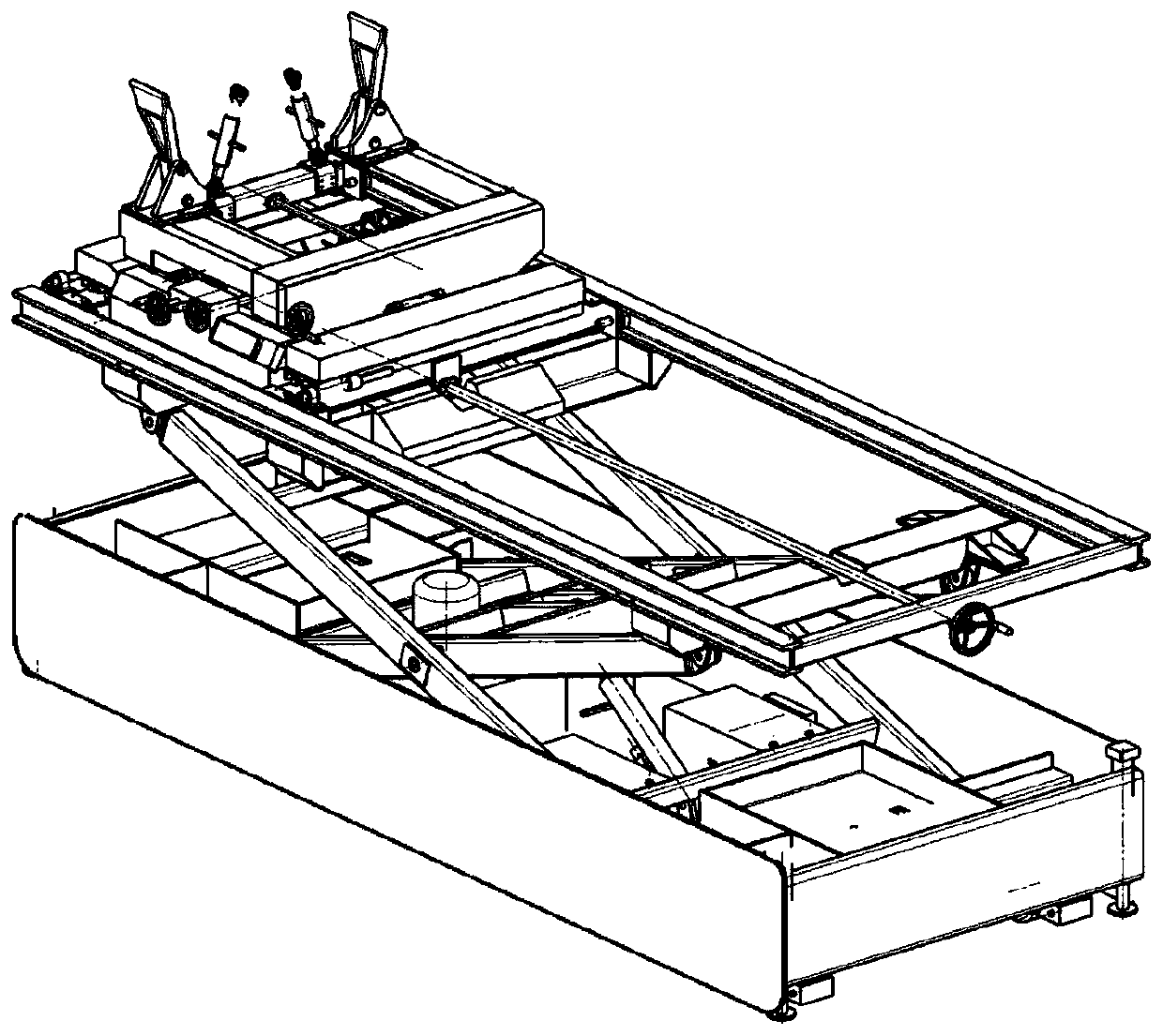

Multi-dimensional posture adjusting platform for airplane ground loading maintenance

ActiveCN110901947AShrink volume is smallCompact structureAircraft maintainanceControl theorySupport point

The invention discloses a multi-dimensional posture adjusting platform for airplane ground loading maintenance, and aims to provide a posture adjusting platform which is convenient to operate, high inworking efficiency and capable of guiding mounting parts to be fed accurately. The method is realized through the following technical scheme: the front fixed supporting point and the rear movable supporting point of the multi-dimensional adjusting platform are hinged through a fork frame rear supporting point and a fork frame front supporting point; the cross lifting adjusting mechanism translates along the Z direction; y-direction translation of first-stage longitudinal movement adjustment is achieved along a first-stage sliding rail of a first-stage longitudinal adjustment mechanism througha screw rod connected with a wide-side first-stage adjustment hand wheel, and Y-direction translation of second-stage longitudinal movement adjustment is achieved by a pulley assembly along a second-stage longitudinal adjustment mechanism installation guide rail; the transverse adjusting mechanism moves along the assembled inner slide rail to realize X-direction translation of transverse and heading adjustment; the direction fine adjustment mechanism changes the heights of the front bearing fulcrum and the rear bearing fulcrum of the second-stage bearing frame through the proportional connecting rod supporting mechanism to achieve pitching adjustment, transverse rolling adjustment and Z-direction height fine adjustment.

Owner:CHENGDU KAITIAN ELECTRONICS

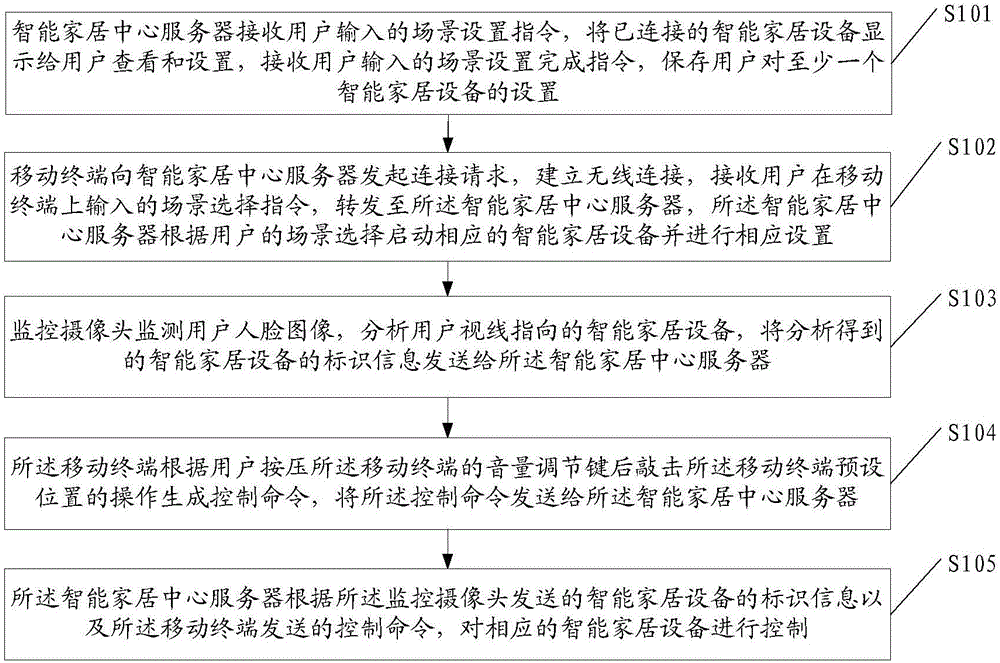

Method for selecting scene based on mobile terminal and system

InactiveCN106569467ASimple and convenient controlImprove user experienceComputer controlProgramme total factory controlSurveillance cameraComputer terminal

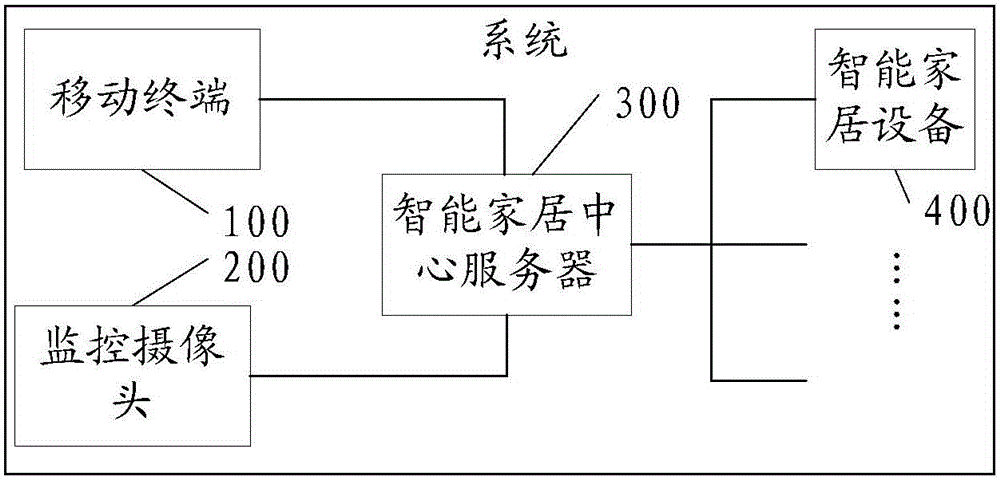

The embodiment of the invention discloses a method for selecting a scene based on a mobile terminal and a system. The method comprises the steps that a smart home central server stores a plurality of scenes according to setting of a user; the mobile terminal establishes wireless connection with the smart home central server, and forwards scene selection of the user to the smart home central server so as to start corresponding smart home equipment and perform corresponding setting; a monitoring camera monitors a face image of the user, analyzes smart home equipment to which the sight of the user points, and sends identification information of the smart home equipment acquired by analysis to the smart home central server; the mobile terminal generates a control command according to an operation that the user presses a volume adjustment key of the mobile terminal and then knocks on a preset position of the mobile terminal, and sends the control command to the smart home central server; and the smart home central server performs control on the corresponding smart home equipment according to the identification information and the control command. The convenience in controlling the smart home equipment can be improved by adopting the method and the system disclosed by the embodiment of the invention.

Owner:SHENZHEN ZHILE TECH LTD CO

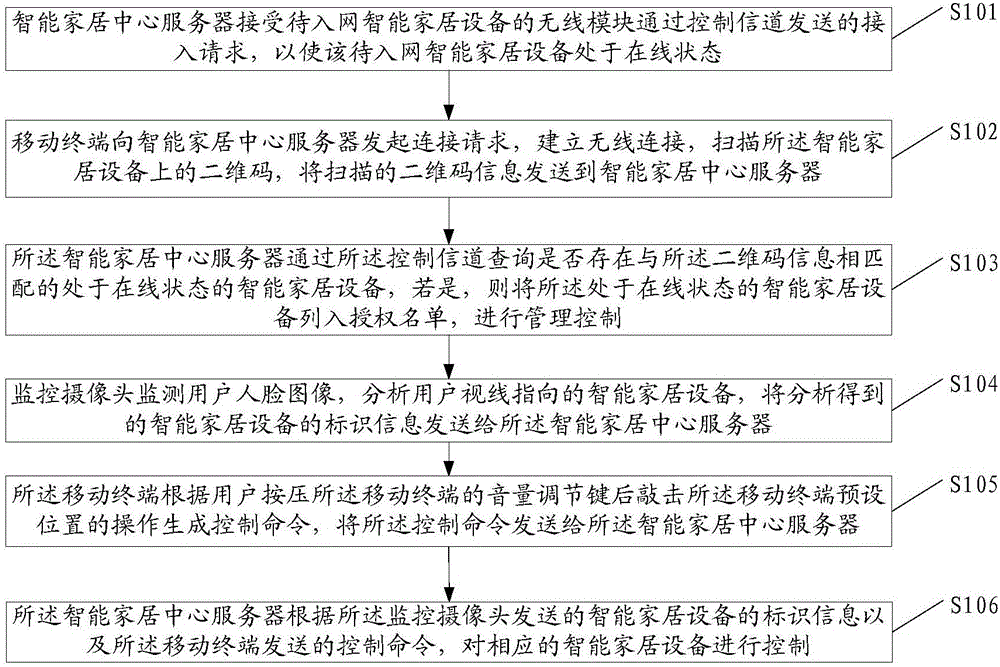

Method and system for managing smart home based on mobile terminal

InactiveCN106549838AImprove user experienceEasy to useComputer controlCo-operative working arrangementsSurveillance cameraComputer terminal

Embodiments of the invention disclose a method and a system for managing smart home based on a mobile terminal. The method comprises the following steps that a smart home center server establishes a connection with the mobile terminal, the mobile terminal scans two-dimensional code information on smart home equipment, sends the two-dimensional code information to the smart home center server to verify and allows network access of the smart home equipment after authentication; a monitor camera monitors a facial image of a user, analyzes the smart home equipment pointed by the line of sight of the user and sends identification information of the smart home equipment, which is obtained by analysis, to the smart home center server; the mobile terminal generates a control command according to the operations of the user of tapping a preset position of the mobile terminal after the user presses a volume adjustment key of the mobile terminal and sends the control command to the smart home center server; and the smart home center server controls the corresponding smart home equipment according to the identification information and the control command. Through adoption of the method and the system, the convenience for controlling the smart home equipment can be improved.

Owner:SHENZHEN ZHILE TECH LTD CO

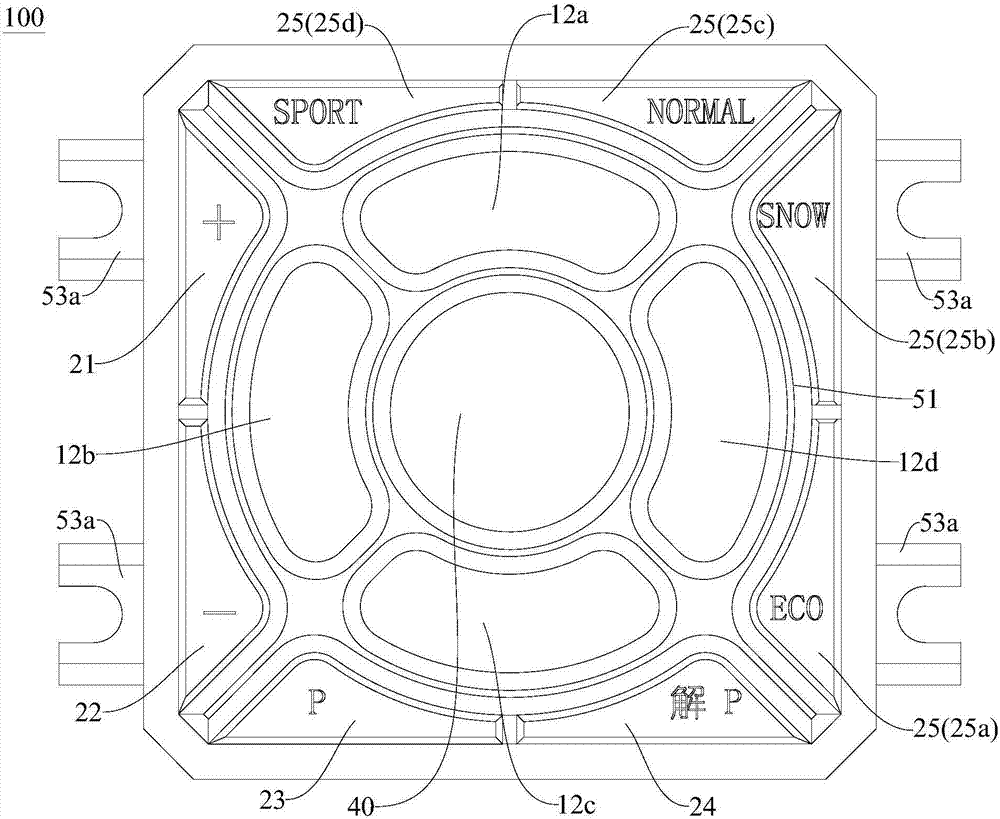

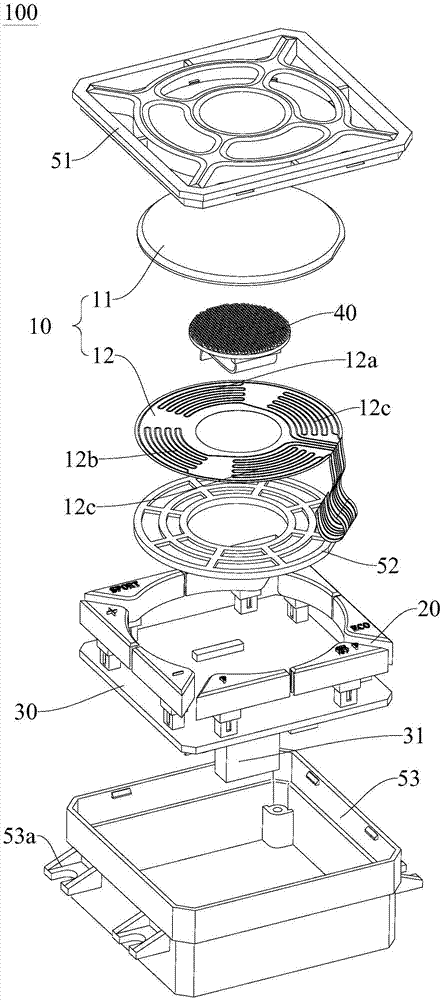

Electronic shifter

ActiveCN108006213AConvenient touch operationImprove operating experienceGearing controlComputer moduleOperation mode

The invention discloses an electronic shifter. The electronic shifter comprises a control module, a touch assembly and a key assembly, wherein the control module is suitable for being connected with aspeed changer; the touch assembly is provided with a plurality of gear sensing regions for receiving touch commands and is connected with the control module; the key assembly is connected with the control module; and the control module controls the speed changer according to signals transmitted by the touch assembly and / or the key assembly. According to the electronic shifter of an embodiment ofthe invention, by an operation mode of combining touch and keys, the electronic shifter simultaneously has the characteristics of simplicity and reliability of a key mode and the characteristics of speediness in touch operation, the operation experience of the electronic shifter is good, and meanwhile, misoperation of the electronic shifter can be avoided easily.

Owner:GREAT WALL MOTOR CO LTD

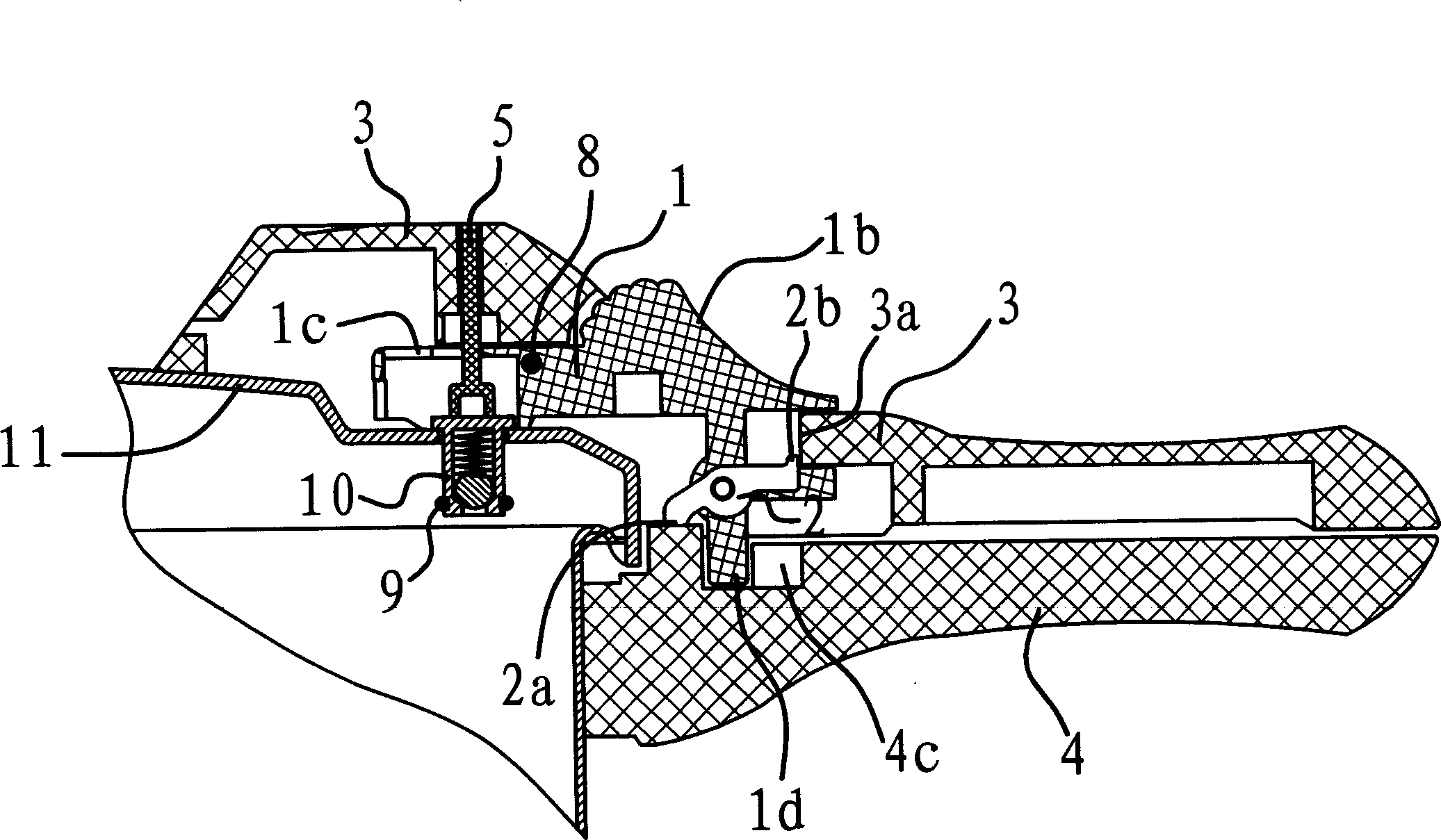

Cover closing and opening safety device for pressure cooker

Disclosed a pressure-cooker on-off lid safety device belongs to commodity technique, solving the complexity and insecurity of prior device. This pressure-cooker on-off lid safety device is mounted between upper handgrip and lower handgrip, the upper handgrip is equipped a push-plate whose fore has a display panel, a safety valve is mounted on the pan lid which is opposite the display panel, in the upper handgrip a slide shoes mounted besides the push-plate is hinged with push-plate and a spring between them operates the boarder of slide shoes top to push one flat surface of upper handgrip, and an inclined surface is mounted on the lower handgrip opposite the slide shoes. Said pressure-cooker on-off lid safety device has simple structure and safety, while the forced angle of slide shoes in use is little conducing less shape distortion and prolonging working life.

Owner:ZHEJIANG SUPOR CO LTD

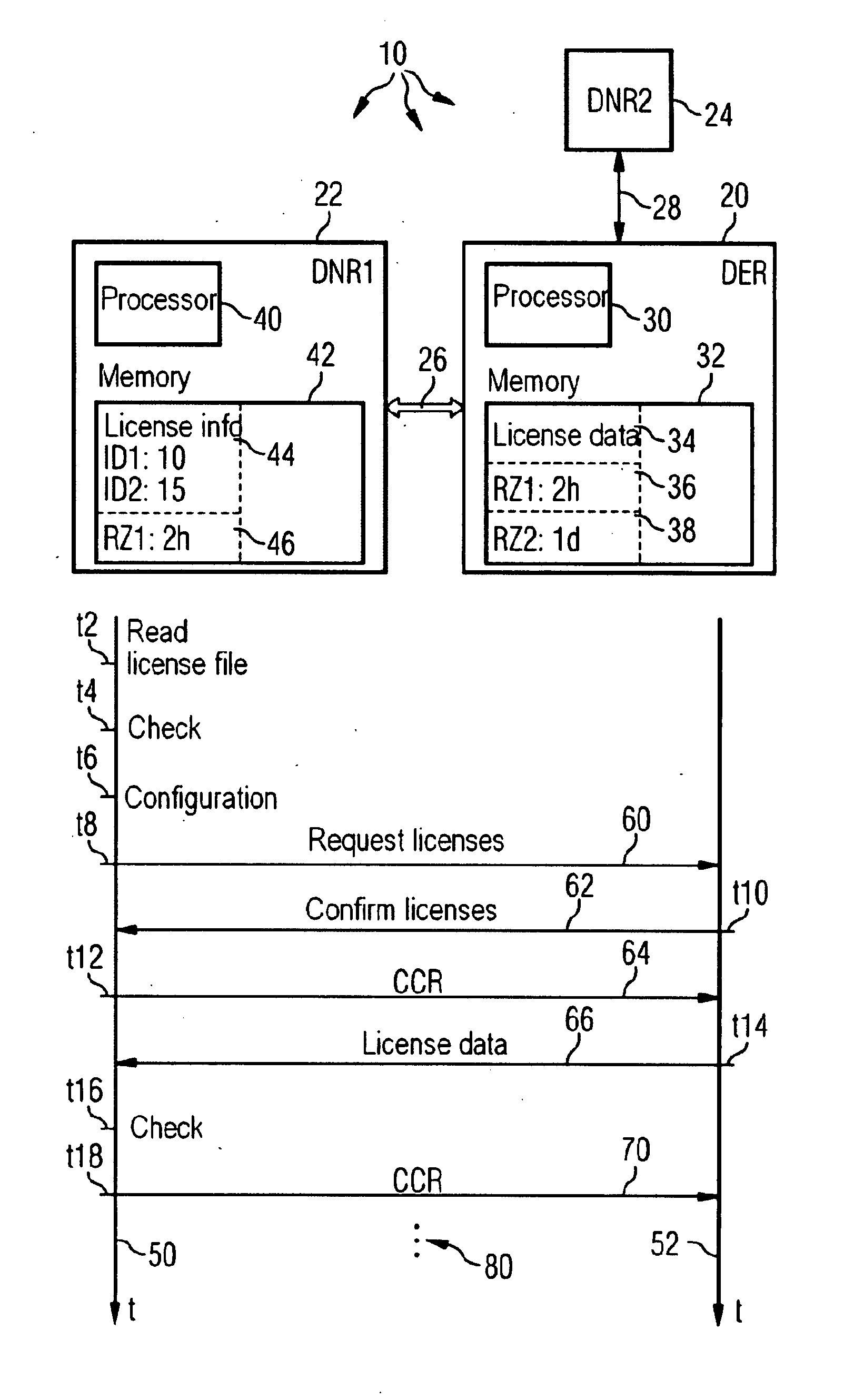

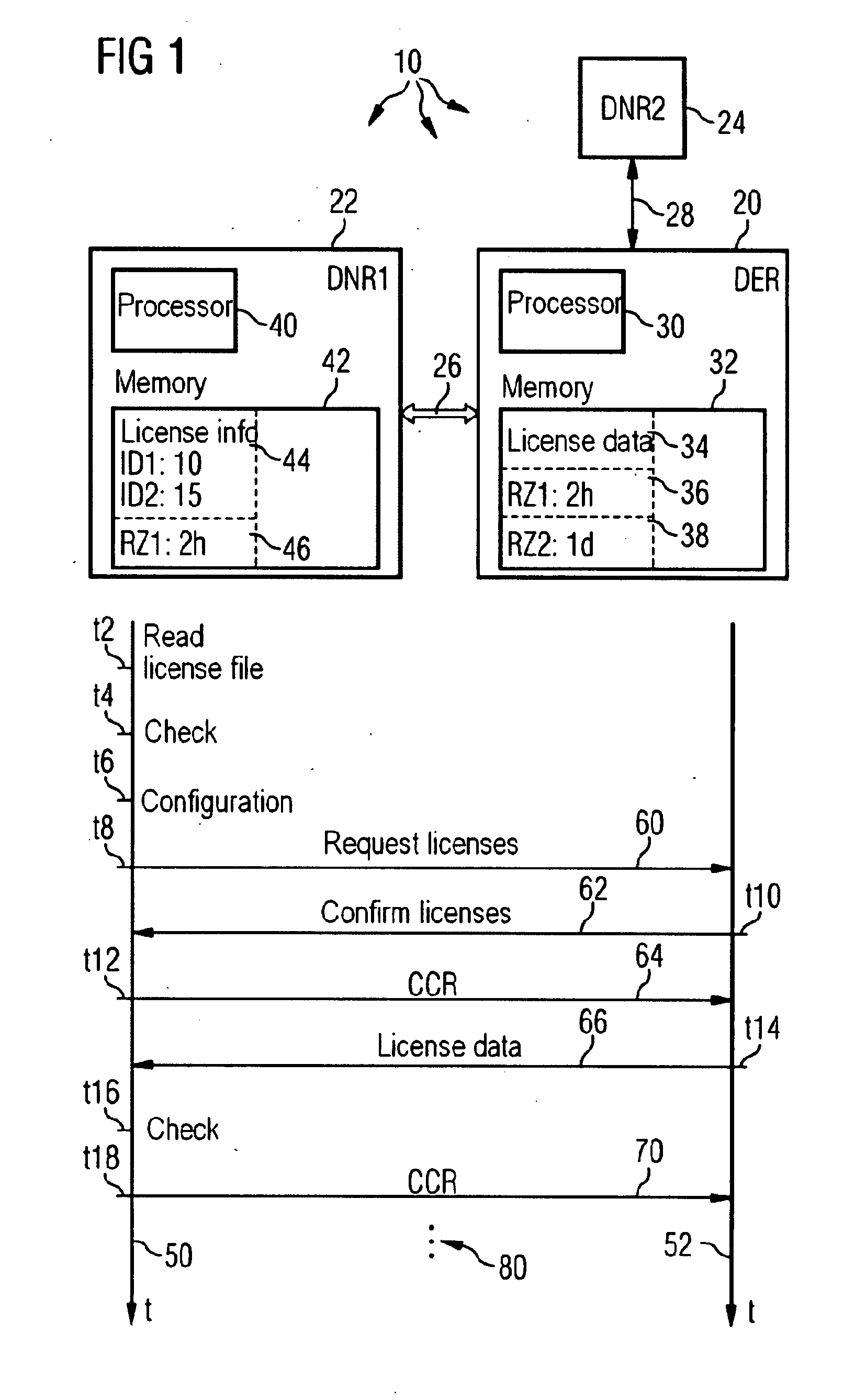

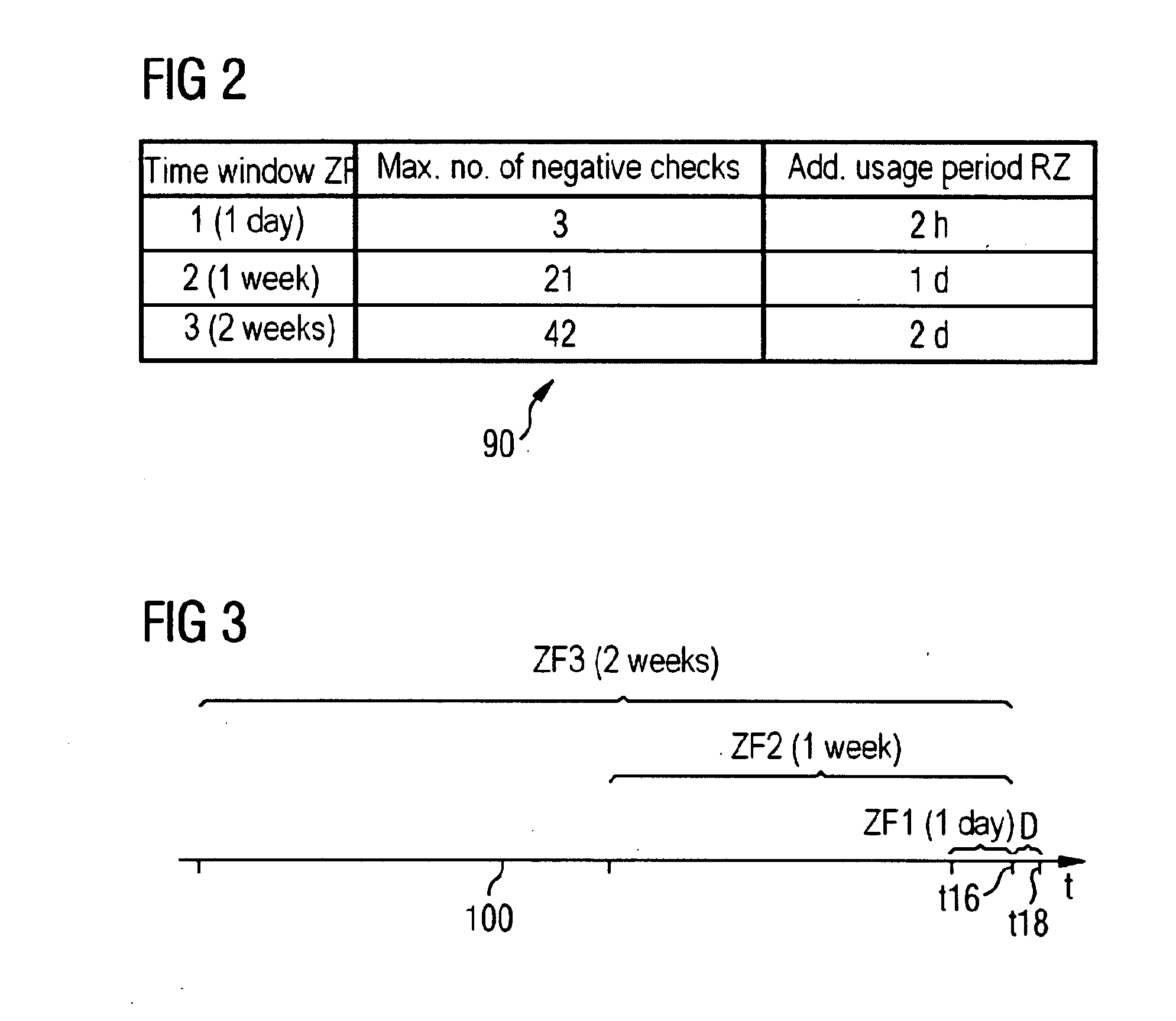

Method for Operating a Data Communications Network Using License Data and Associated Device Network

InactiveUS20080147850A1Avoid misusePrevention is simpleDigital data processing detailsAnalogue secracy/subscription systemsComputer monitorService provision

Owner:NOKIA SIEMENS NETWORKS GMBH & CO KG

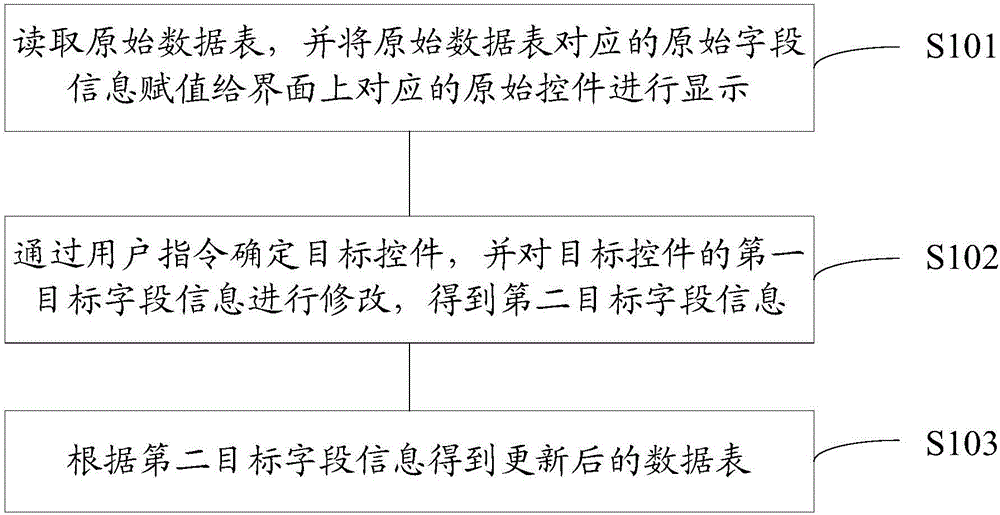

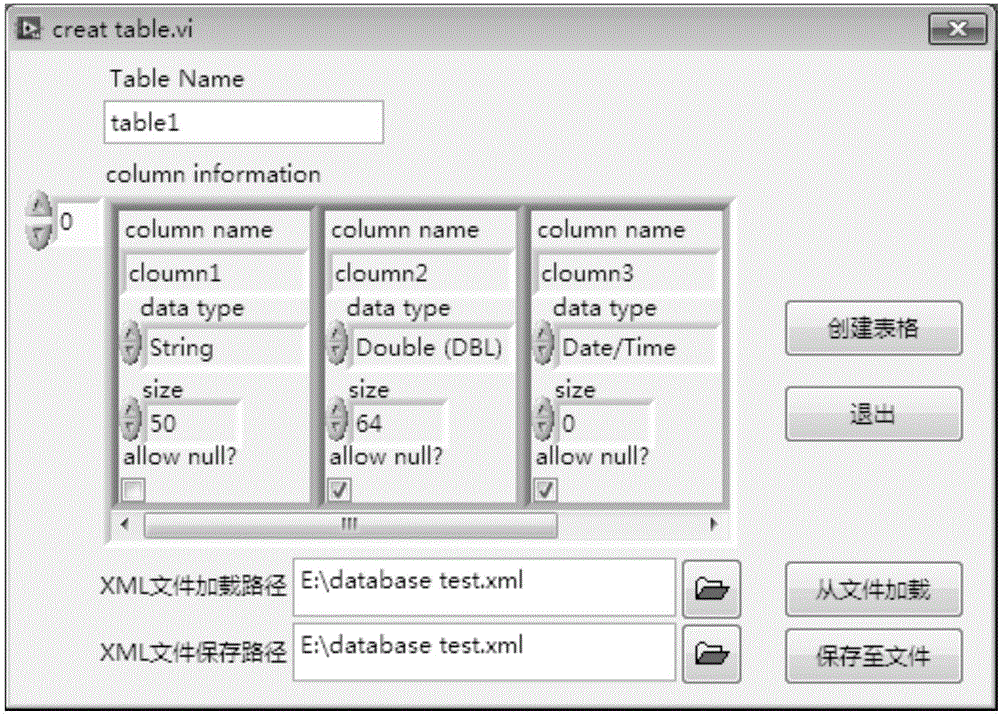

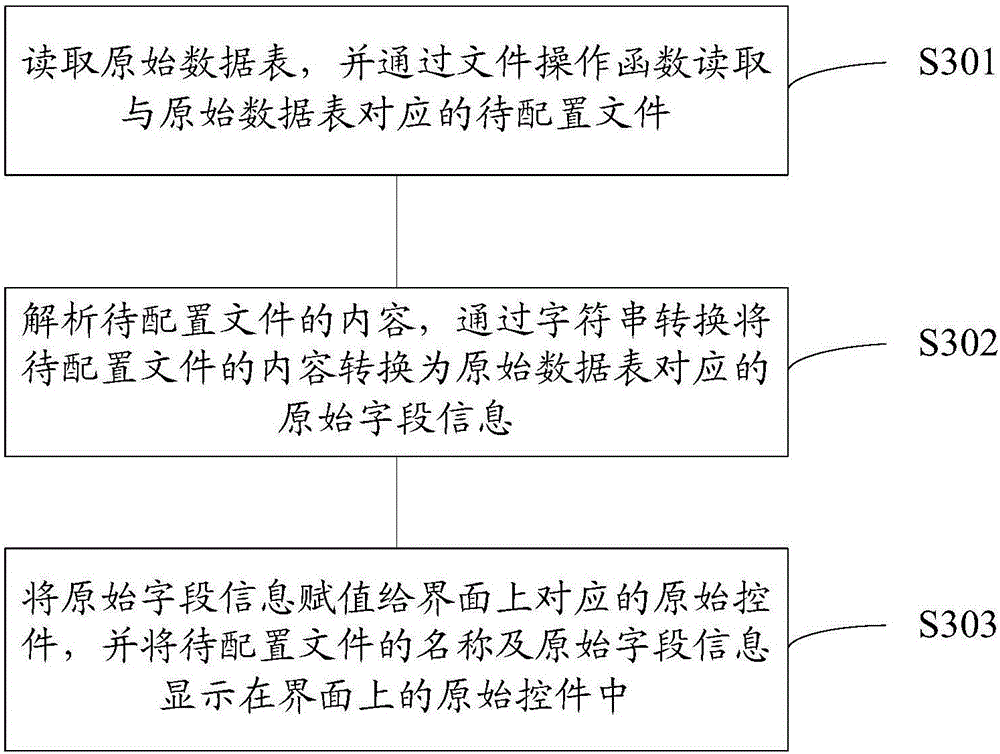

Operation method and system for data table in database

ActiveCN106598612AEnsure correct storageLess prone to misuseDatabase updatingVisual/graphical programmingUser needsManagement tool

The invention discloses an operation method and an operation system for a data table in database, applied to LabVIEW software. The method is developed based on a LabVIEW language, and comprises the steps of firstly displaying original field information corresponding to the data table in an original control on an interface, determining a target control needing to be modified according to a user command; then modifying first target field information of the target control according to a user need, thus acquiring modified second target field information; and at last acquiring the updated data table according to the second target field information. According to the method and the system provided by the invention, the user can directly display all field information of the data table on the interface control, then the field information in the control is modified, added or deleted according to a test index, processing operation performed by professional by using a database edition management tool is not needed, the field information in the control can be directly operated, misoperation is not easy to occur, and correct storage of data is ensured.

Owner:BEIJING RUNKE GENERAL TECH

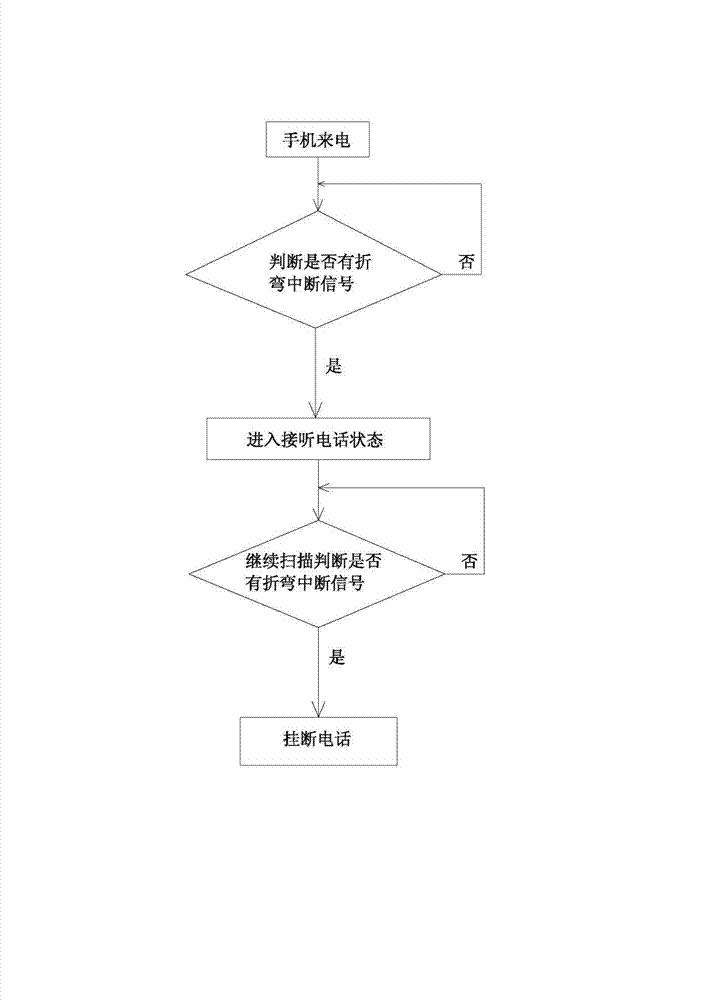

Method for answering and hanging up based on mobile phone with flexible display screen

InactiveCN102957798AImprove user experienceInnovative waySubstation equipmentEngineeringHuman–computer interaction

The invention discloses a method for answering and hanging up based on a mobile phone with a flexible display screen. The method comprises the steps that (1) when the mobile phone receives an incoming call, a central processing unit scans to judge whether a bending interrupt signal of the flexible display screen of the mobile phone is available or not; (2) when the central processing unit scans the bending interrupt signal of the flexible display screen of the mobile phone in a predetermined time, the mobile phone enters into a conversation state; and (3) when the mobile phone enters into a conversation state, the central processing unit scans continuously to judge whether the bending interrupt signal of the flexible display screen of the mobile phone is available or not, if so, the mobile phone enters a hanging-up state. According to the method for answering and hanging up based on the mobile phone with the flexible display screen provided by the invention, the display screen is bended to answer and hang up, so that the usage experience of users is enhanced, the operability is improved, and mis-operation is not easy to generate.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

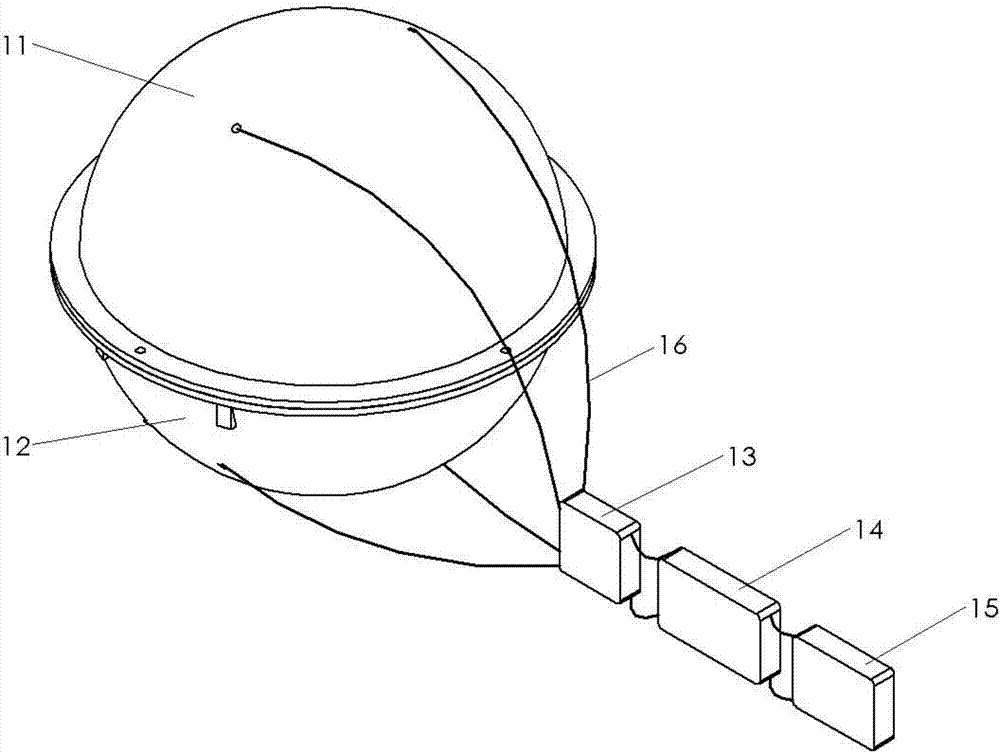

Electromagnetic-piezoelectric composite type wave energy collection device

ActiveCN107086649AApplicable to medium and high frequency vibration occasionsImprove reliabilityBatteries circuit arrangementsPiezoelectric/electrostriction/magnetostriction machinesCantilevered beamElectricity

The invention provides an electromagnetic-piezoelectric composite type wave energy collection device and belongs to the technical field of designing and manufacturing of energy collection devices. The objective of the invention is to achieve that vibration energy of fluctuated waves are acquired to replace a traditional cell to carry out permanent power supply on micro-devices like ocean monitoring wireless sensors. The wave energy collection device comprises an electromagnetic type energy collection structure and a piezoelectric type energy collection structure. A pair of piezoelectric bimorph cantilever arm structures are arranged on two ends of a base. A pair of rectangular magnets are laid on the piezoelectric bimorphs. Two groups of support racks are arranged on a flat plate part of the base. Two ends of each of cylindrical protection cylinders in the support racks are fixed through flanges and protection nets. The protection cylinders are arranged in the middle parts of the piezoelectric bimorph cantilever arm structures. Coil cylinders are arranged in the protection cylinders. The length of each coil cylinder is consistent with that of the corresponding protection cylinder. Coils are laid on the coil cylinders. Magnetic vibrators are arranged in the coil cylinders. Two pairs of rollers are arranged on upper and lower sides of the magnetic vibrators. The wave energy collection device is mainly used for providing power for ocean wireless sensors.

Owner:SOUTHWEST JIAOTONG UNIV

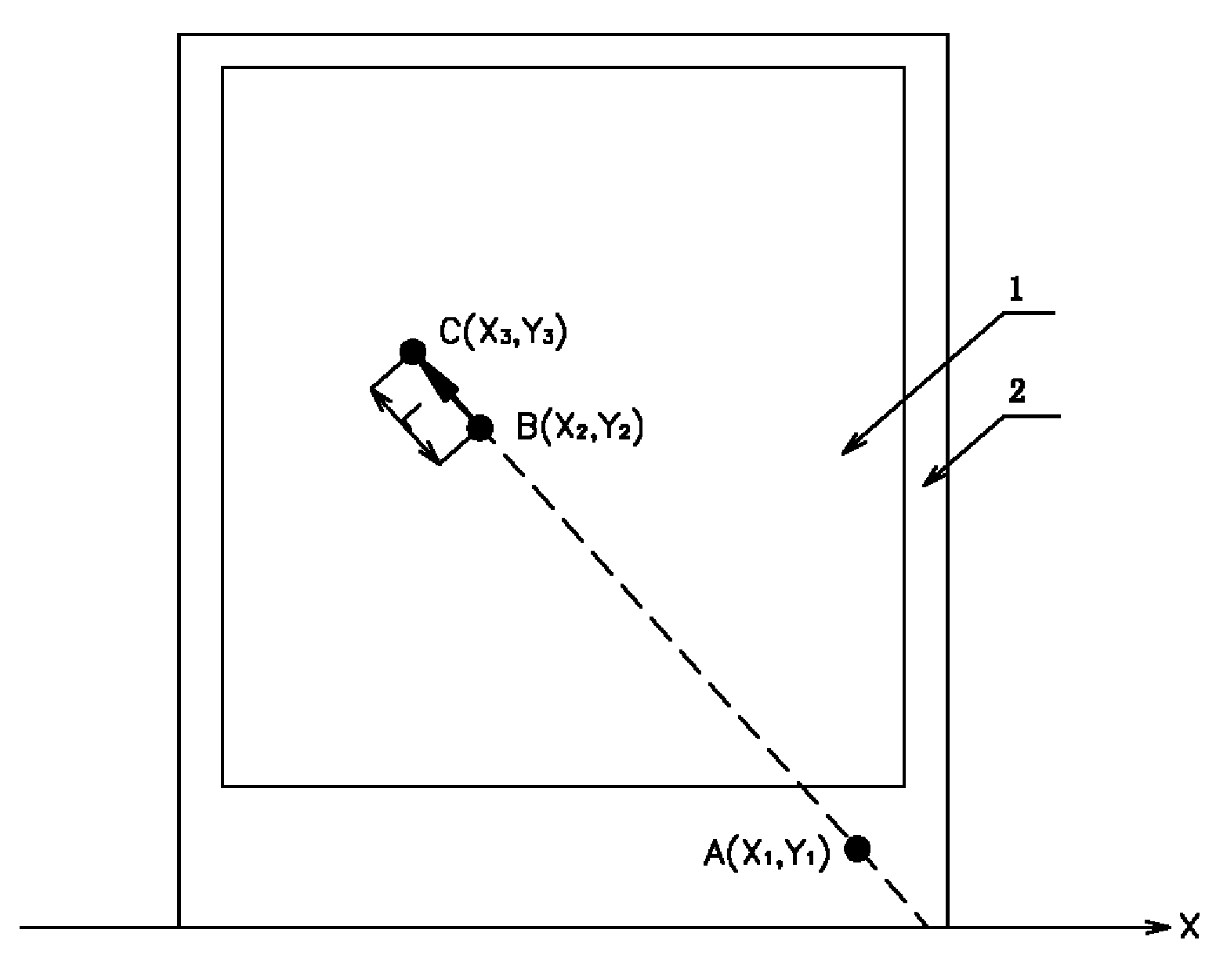

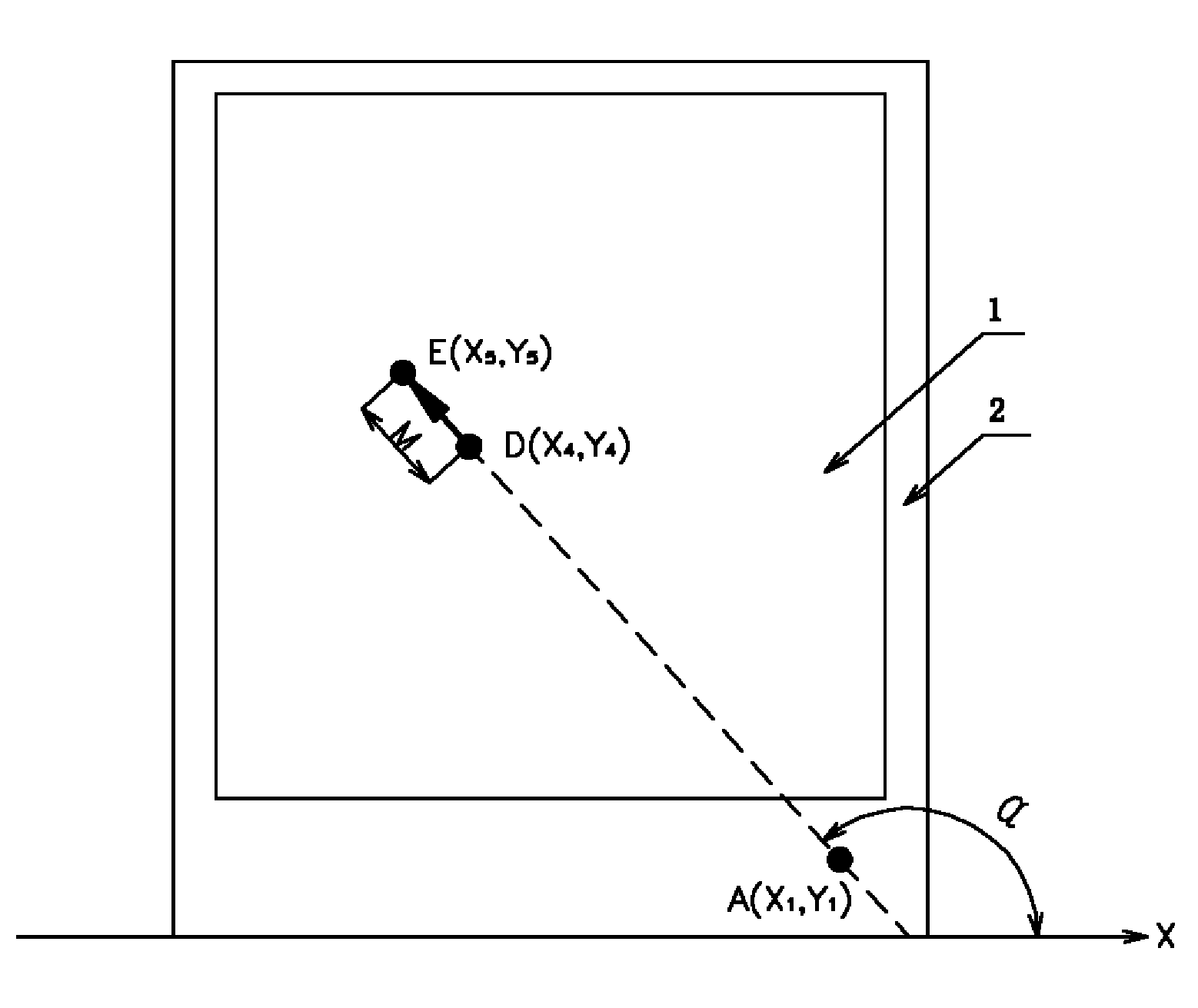

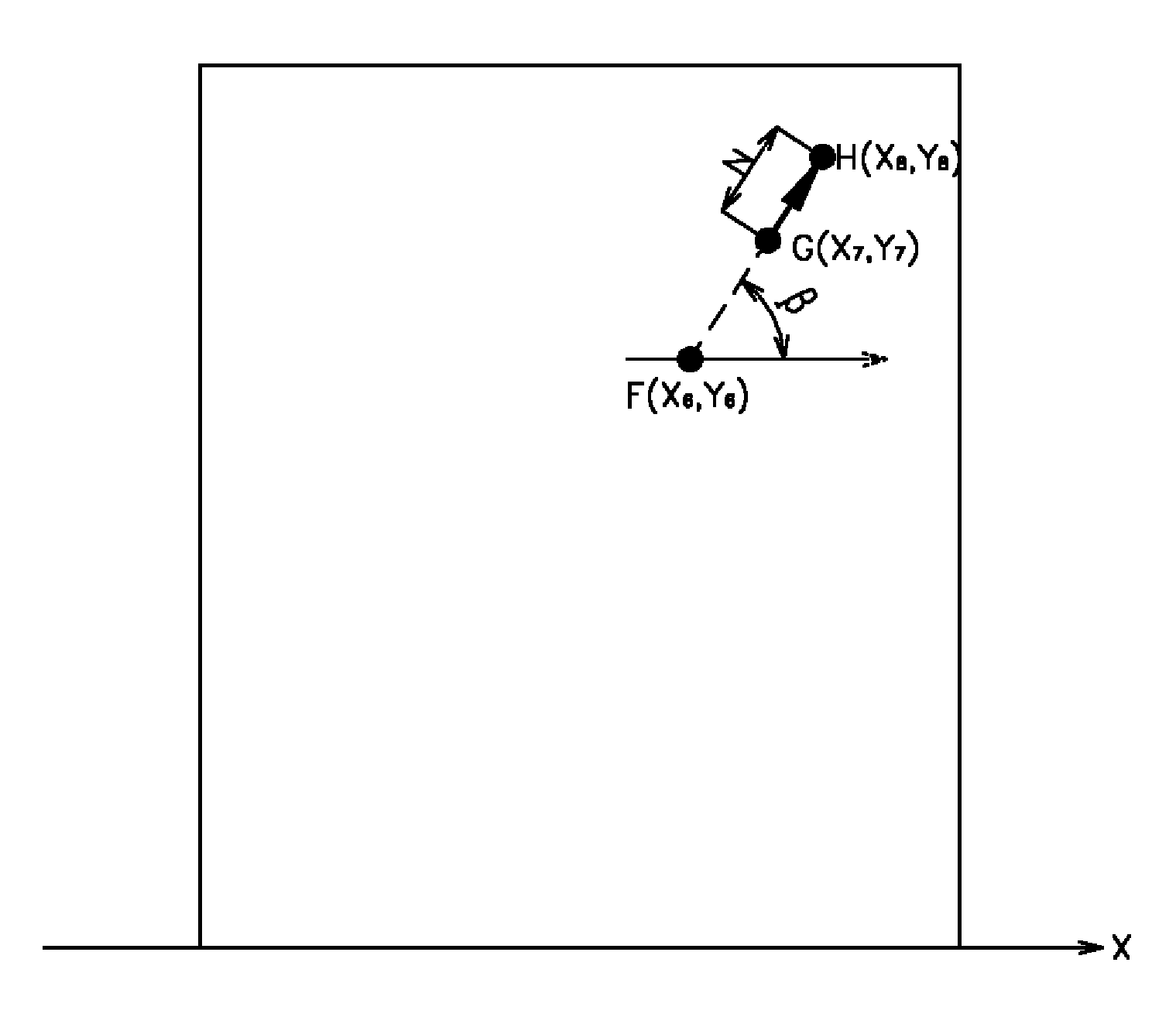

Click method for coordinate setting on small touch screen

InactiveCN101840287AExtended service lifeLess prone to misuseInput/output processes for data processingTouchscreen

Owner:WUXI ARF ELECTRONICS

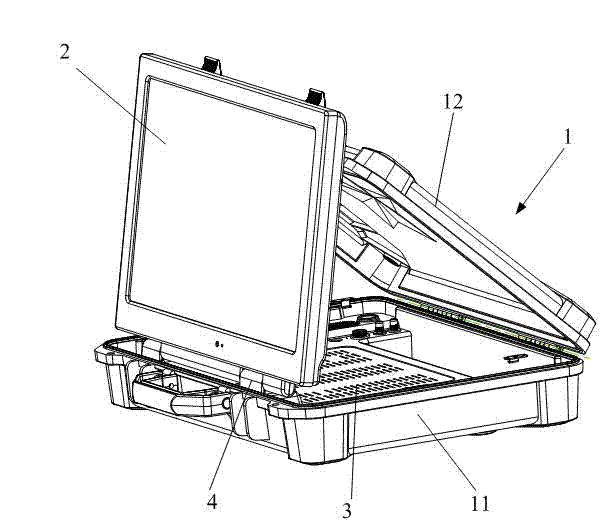

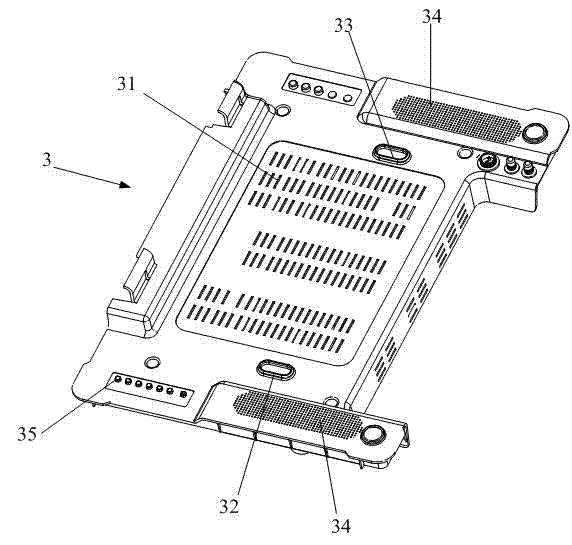

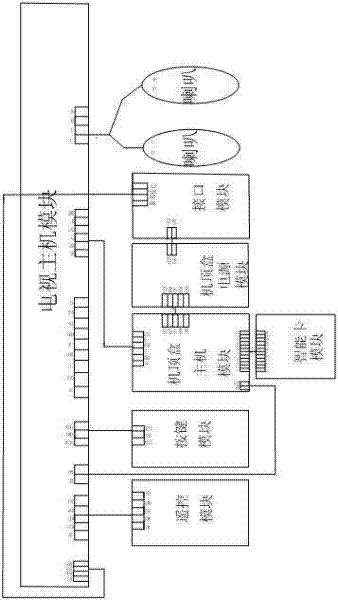

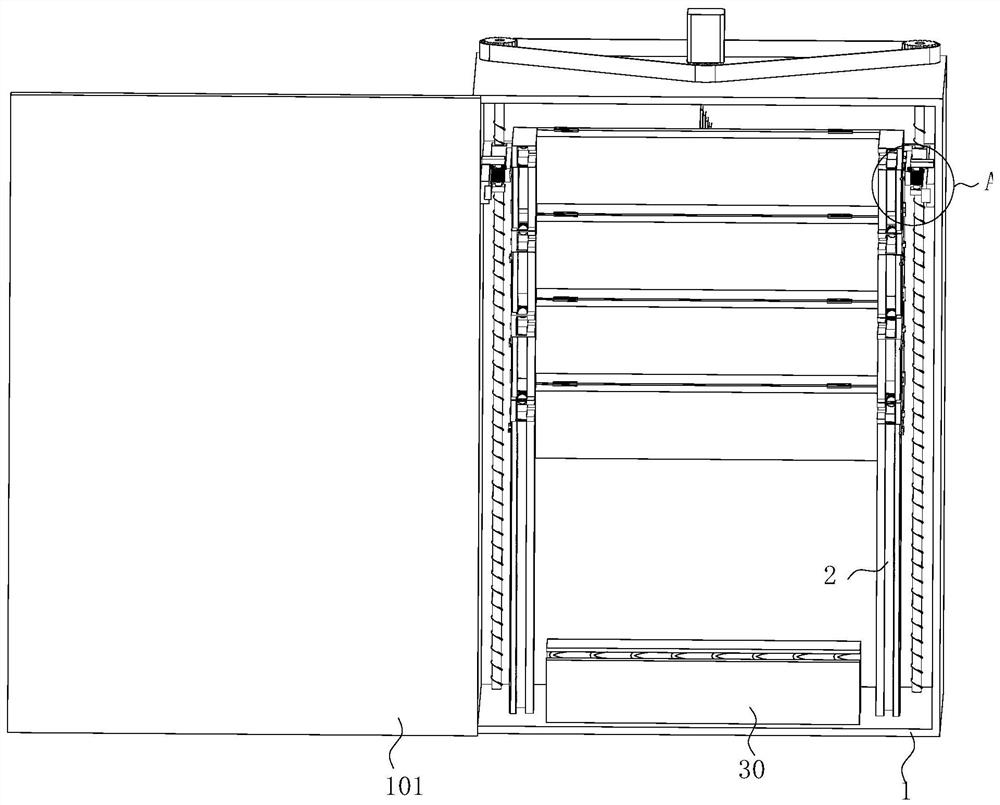

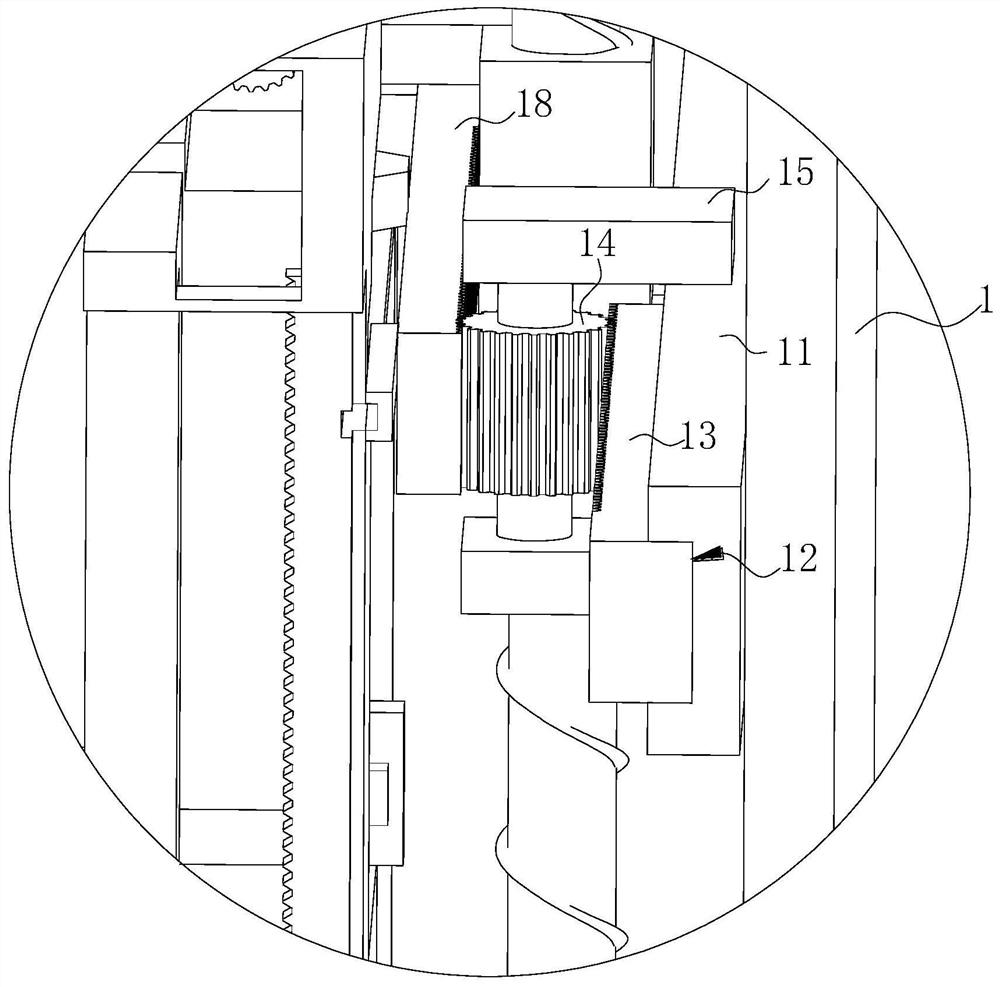

Portable digital television

InactiveCN102421018AMeet the needs of viewing from multiple anglesReasonable structural designTelevision system detailsColor television detailsModularityModular design

The invention provides a portable digital television. On one hand, a reasonable structure design for an integral box is made, so box space is maximally used; and on the other hand, a modular design for interior hardware is made, so structure is simplified, the maintenance is convenient, the volume of the portable digital television is greatly reduced simultaneously, and the portable digital television can be more conveniently carried.

Owner:HISENSE BROADBAND MULTIMEDIA TECH

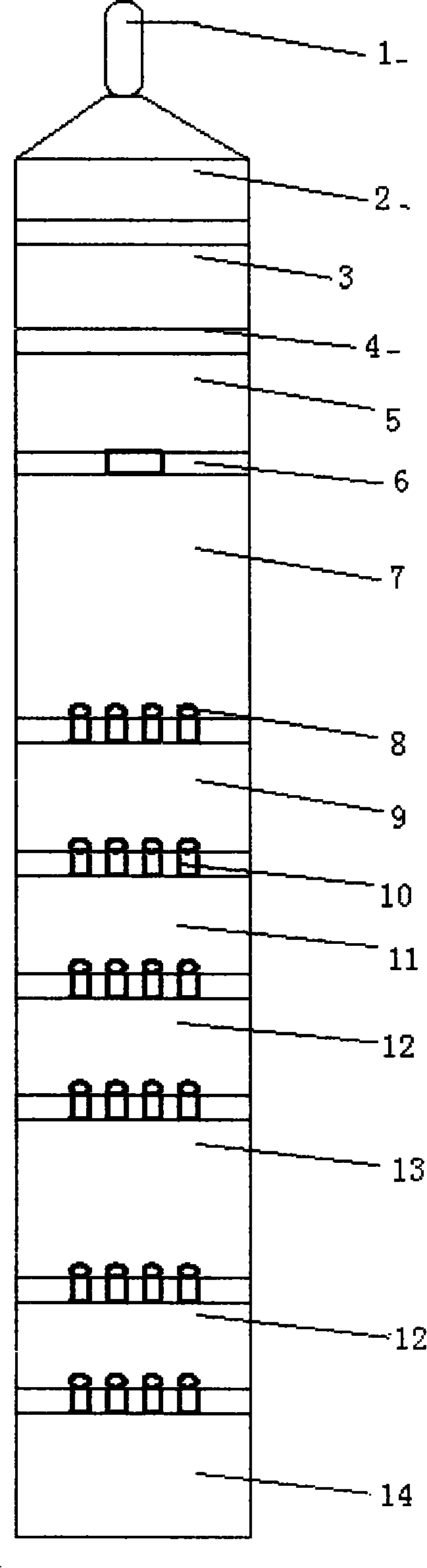

Power distribution cabinet with rapid maintenance function

InactiveCN112038923ASmall footprintEasy maintenanceSubstation/switching arrangement casingsSubstation/switching arrangement boards/panels/desksEngineeringStructural engineering

The invention discloses a power distribution cabinet with a rapid maintenance function in the technical field of power distribution cabinets. The power distribution cabinet comprises a control cabinetbody, wherein two installation frames are fixedly connected to the interior of the control cabinet body, the upper ends of the two installation frames fixedly communicate with a plurality of fixed blocks which are distributed at equal intervals, a lifting groove is jointly formed in the installation frames and the fixed blocks, and the two fixing blocks on the same horizontal line on the left side and the right side are jointly connected with a rectangular mounting plate in a sliding mode through a first T-shaped sliding groove. According to the power distribution cabinet, a U-shaped plate isdriven by a driving mechanism to ascend and descend to a proper position so as to unfold the rectangular mounting plate needing to be positioned and then retreats and descends to a maintenance position, thus when an electric control cabinet is maintained, only the mounting plates of the mounting component needing to be maintained needs to be pushed out, targeted maintenance is carried out, the misoperation phenomenon during maintenance is not likely to occur, the maintenance efficiency is improved, and all the mounting plates are pushed out to occupy a small area, thereby facilitating the maintenance of components close to the inner side of the power distribution cabinet.

Owner:合肥源康信息科技有限公司

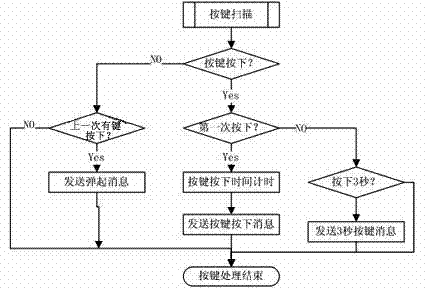

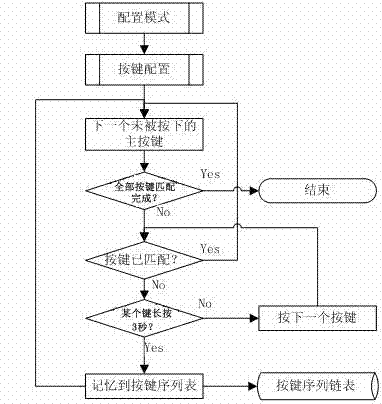

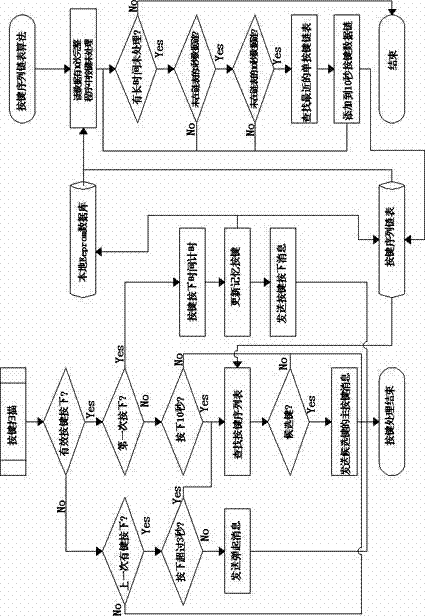

Method for controlling self-adaptive function replacement of control button

The invention provides a method for controlling self-adaptive function replacement of a control button, and relates to button control of electrical equipment. The method is characterized in that manual forced response time, self-adaptive response time, button untreated times and a button sequence chain table are respectively set, and the specific process is that firstly if the untreated times of the pressed control button is reached is checked, if the untreated times is reached, the button sequence chain table is searched to find out a self-adaptive candidate replacing button, a self-adaptive button configuration triggering mode is started, and another button is configured to be the replacing button of the button, and if not, calculation of the untreated times is restarted; when the replacing button is pressed, under the condition of the manual forced response time, replacing button functions which are manually configured are triggered; and when the replacing button is pressed in the self-adaptive response time, the self-adaptive replacing button functions are triggered. By means of the method, self-adaptive replacement of a broken button can be achieved, using is convenient, and the service lives of a button system and a whole machine can be prolonged.

Owner:WUXI FILIN ELECTRONICS CO LTD

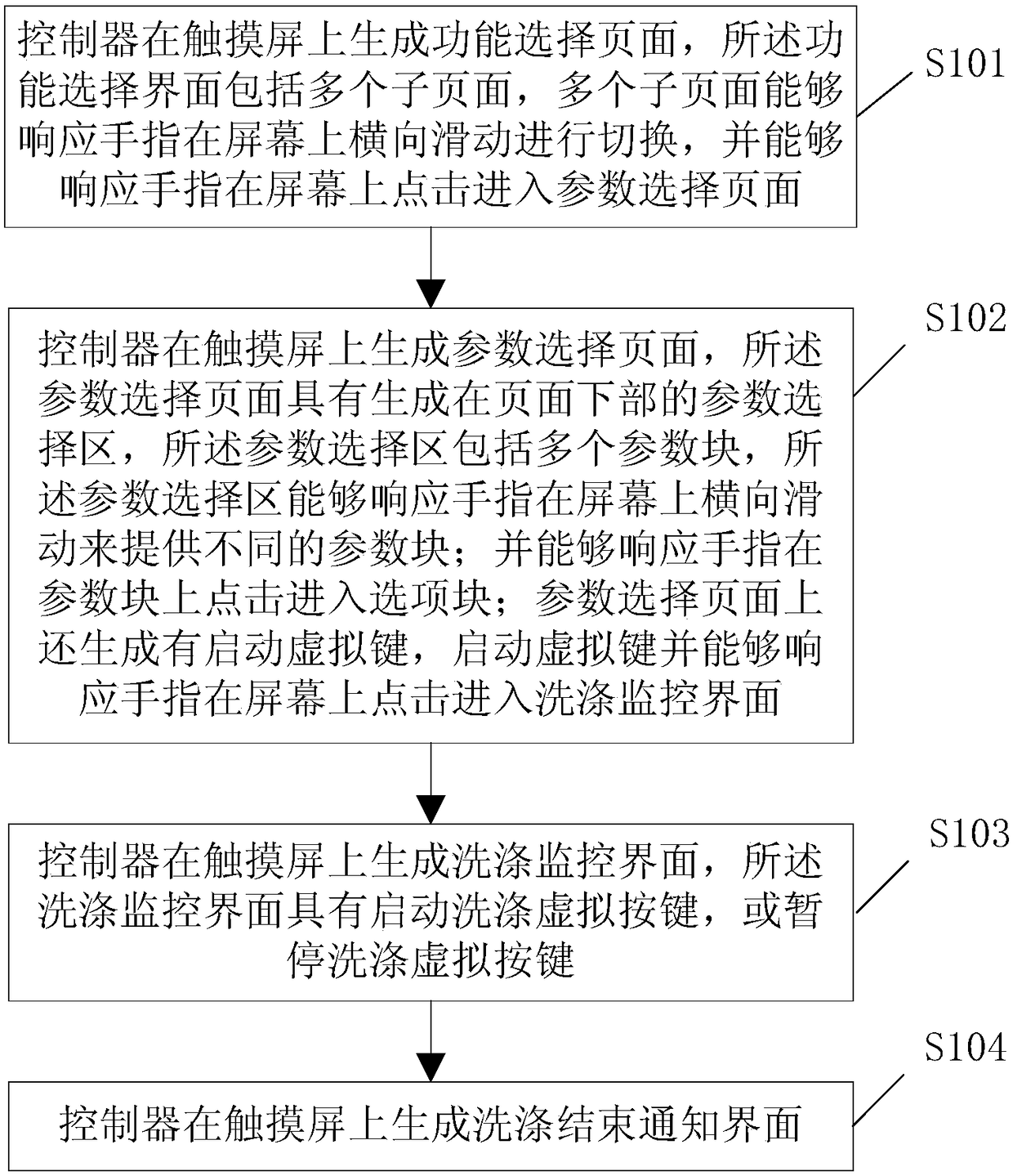

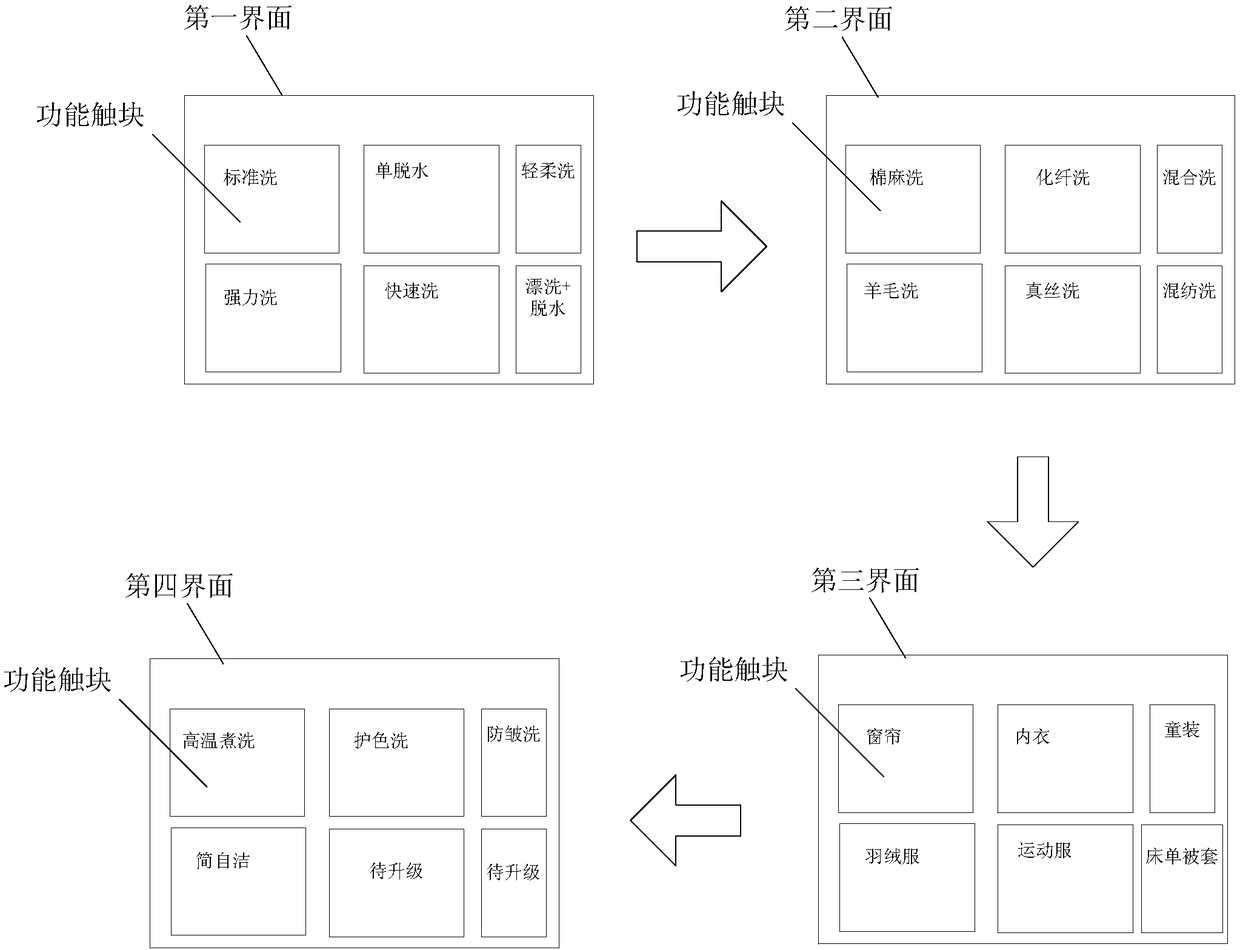

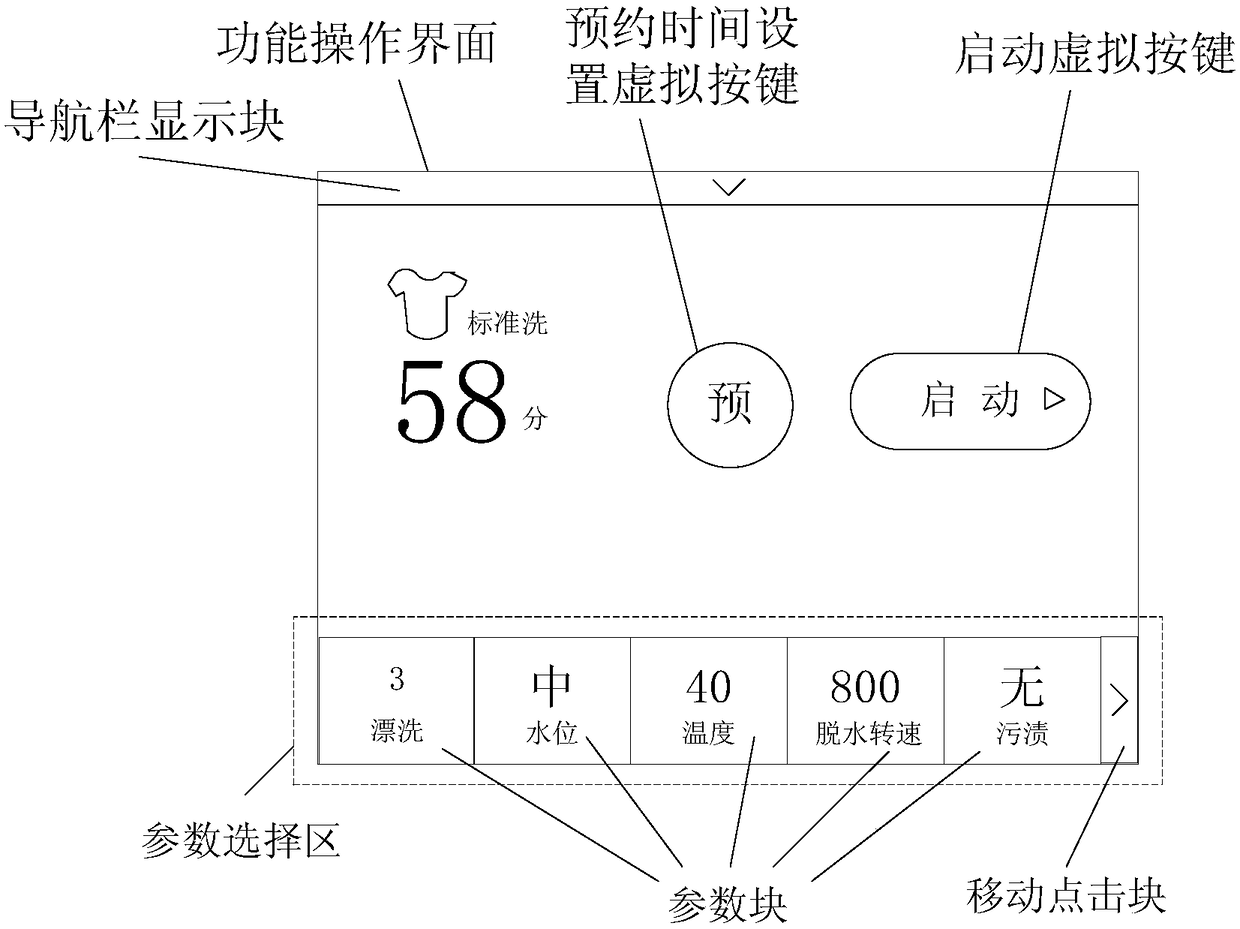

Display method for control interface of washing machine

InactiveCN108951001AReasonable arrangement of touch keysNot easy to misuseOther washing machinesTextiles and paperTouchscreen

The invention discloses a display method for a control interface of a washing machine, comprising: a controller generates a function selection page on a touch screen; the controller generates a parameter selection page on the touch screen; the controller generates a washing monitor interface on the touch screen; the controller generates a washing finish notification interface on the touch screen.The parameter selection page has a parameter selection area generated at a lower part of the page, including a plurality of parameter blocks. The parameter selection area can provide different parameter blocks by responding to fingers swiping transversely on the screen. The area can also enter selection blocks by responding to clicks of the fingers on the parameter blocks. A start virtual button is generated on the parameter selection page and is capable of entering the washing monitor interface by responding to clicks of the fingers on the screen. The washing monitor interface has a start washing virtual button or a stop washing virtual button. The method has the following beneficial effects: (1) touch buttons of touch screen display interfaces are configured more reasonably; (2) a user is not likely to operate by mistake when clicking the buttons.

Owner:SHANGHAI XIAOJI INTERNET TECH CO LTD

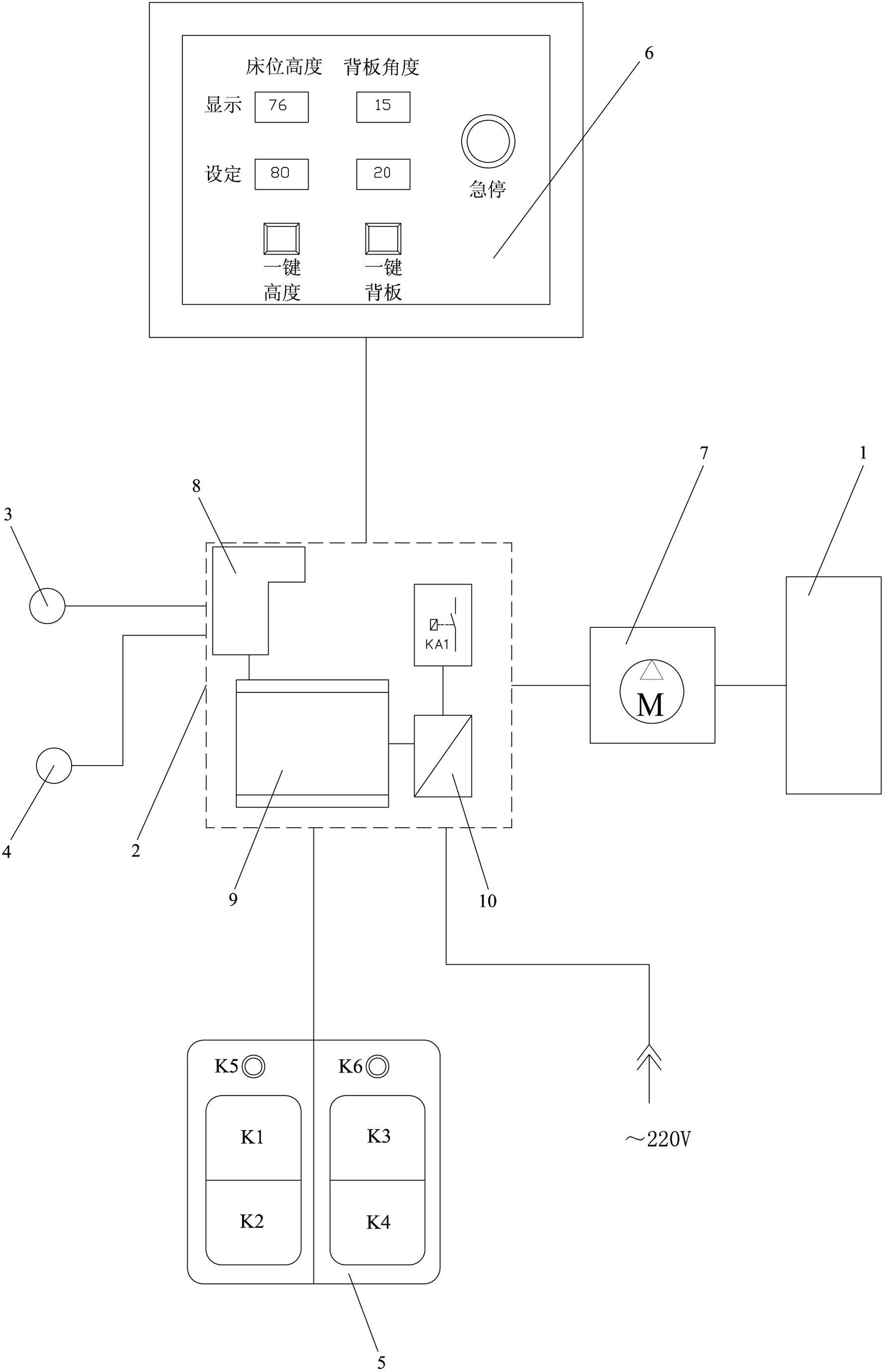

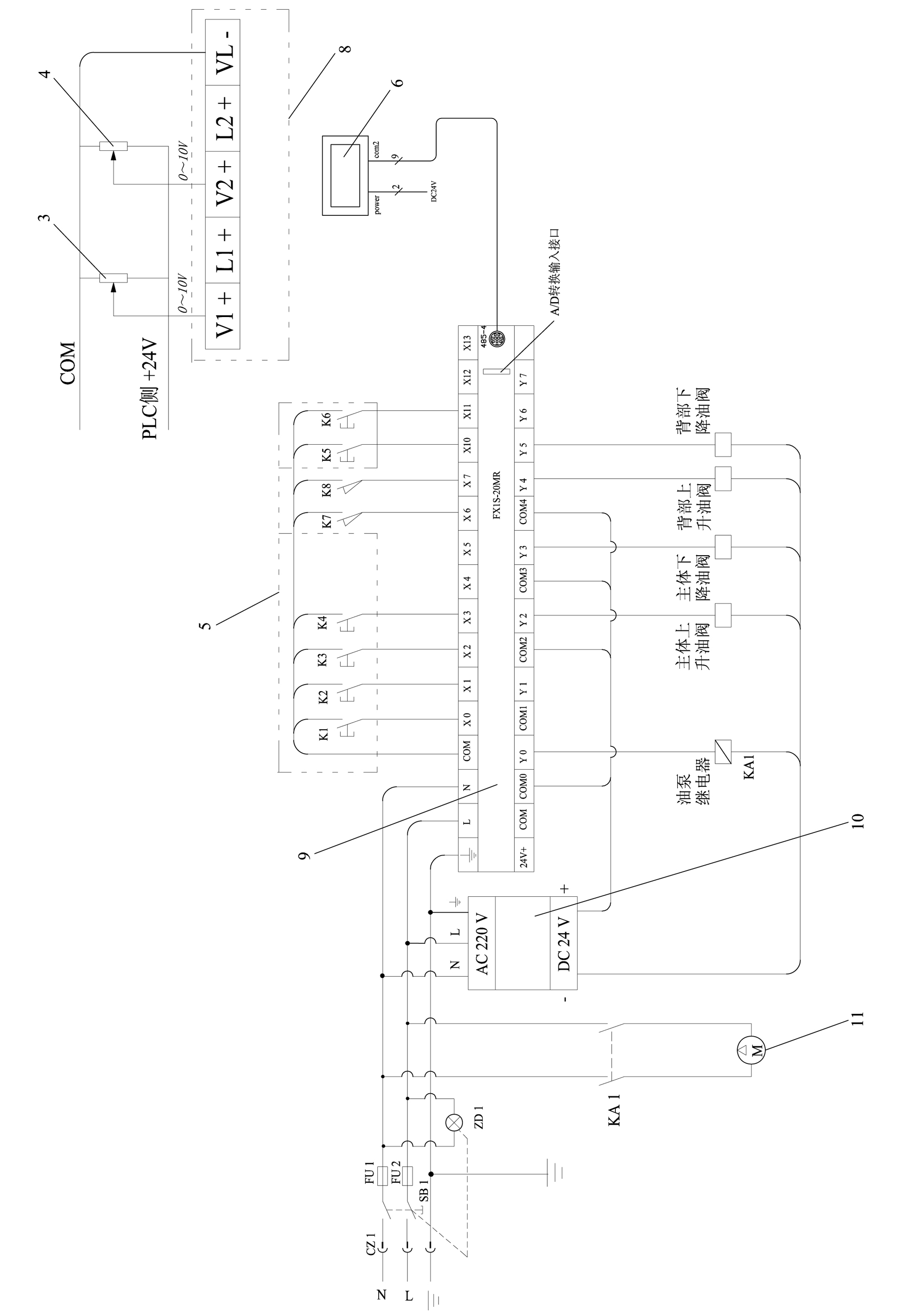

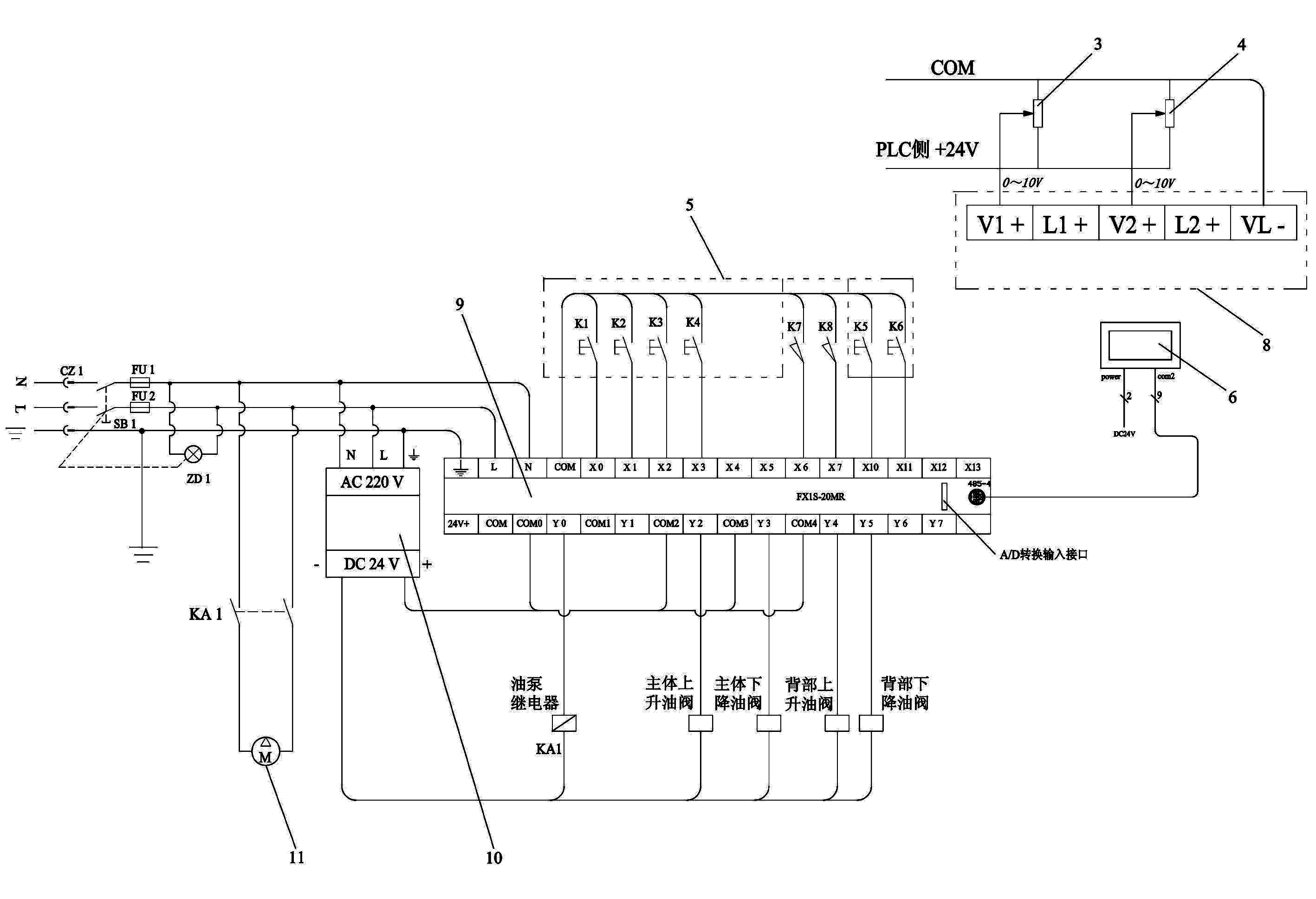

Operating table control device

InactiveCN102008382AEasy to operateLess prone to misuseOperating tablesHuman–machine interfaceControl system

The invention relates to an operating table control device, which is arranged on an operating table provided with a bed and a back board. The operating table control device comprises an electric control system, a bed height potentiometer, a back board angle potentiometer, a switch, a man-machine interface and an implementation system, wherein a control program is downloaded in the electric control system; the bed height potentiometer is electrically connected with the electric control system and is used for detecting height parameters of the bed; the back board angle potentiometer is electrically connected with the electric control system and is used for detecting angle parameters of the back board; the switch is electrically connected with the electric control system; the man-machine interface is electrically connected with the electric control system; and the implementation system is electrically connected with the electric control system, and an output end of the implementation system is connected with the operating table. Because the operating table control device can preset the body position of the operating table, the operating table control device only needs simple operation to ensure that the operating table reaches the preset body position in each use; besides, is easy and quick to operate, and is difficult to generate misoperation.

Owner:TAICANG KANGHUI TECH DEV

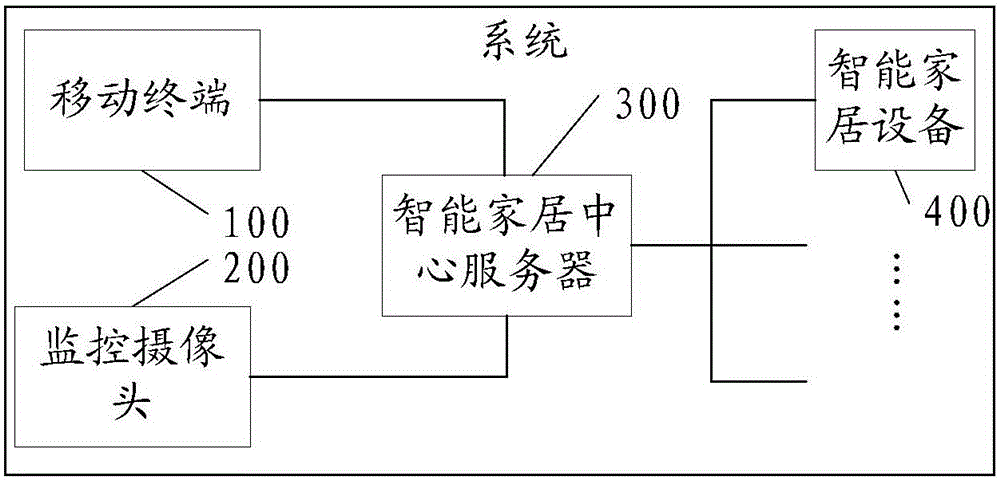

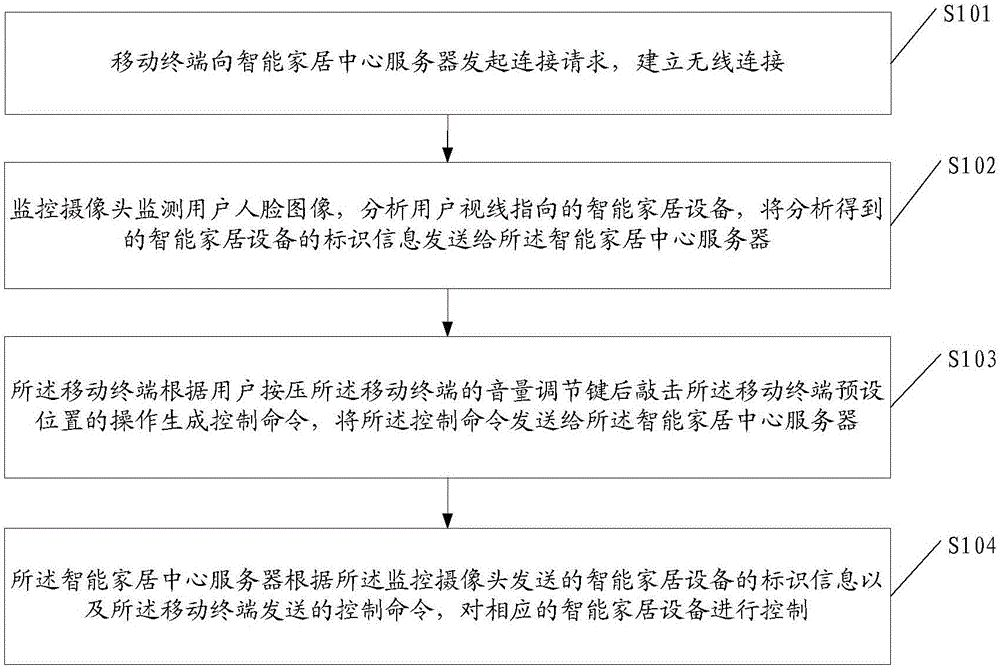

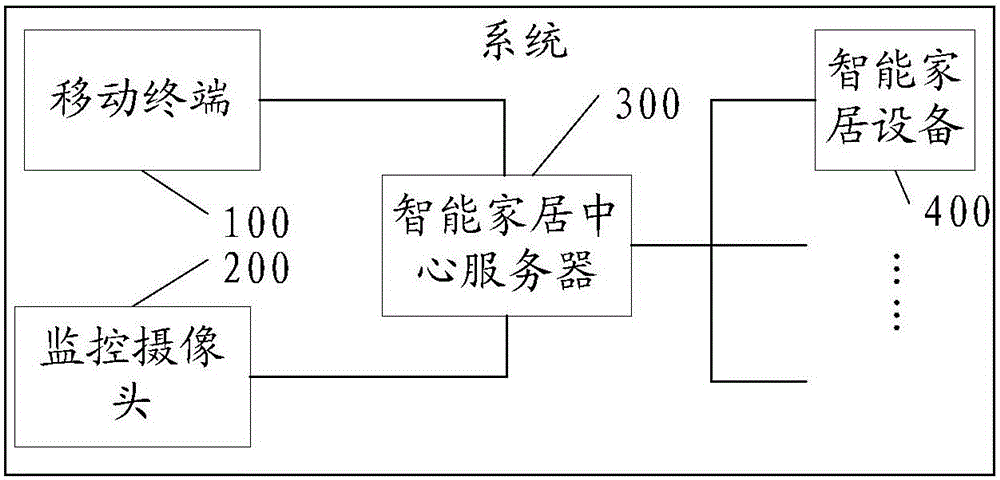

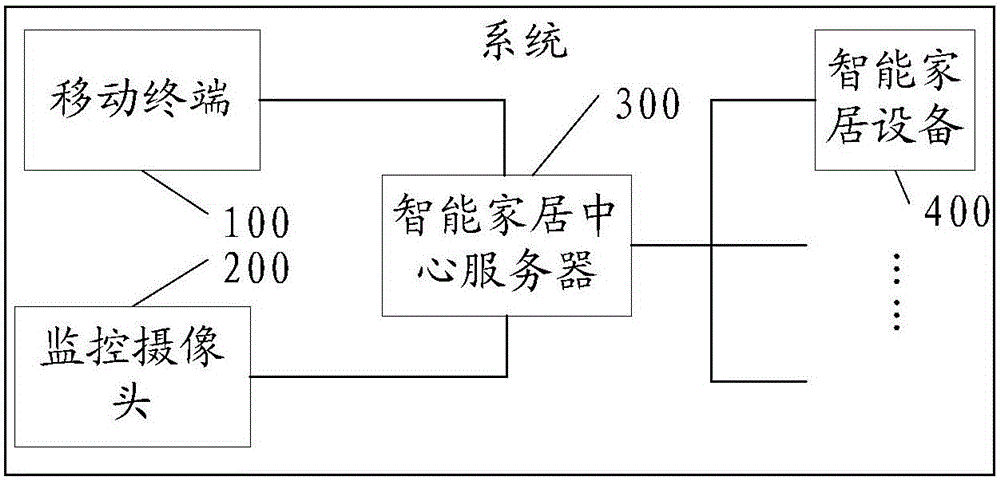

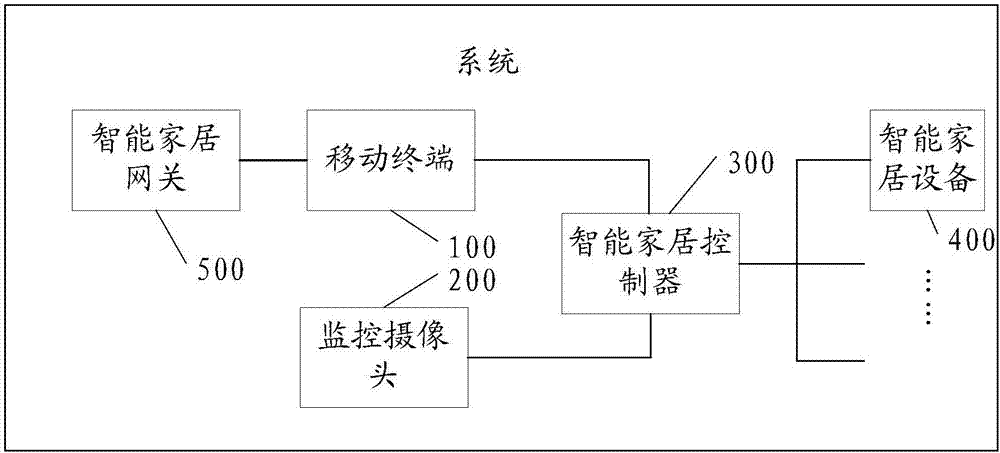

Control method and system based on mobile terminal

InactiveCN106412081AImprove user experienceEasy to determineInput/output for user-computer interactionComputer controlSurveillance cameraComputer terminal

The embodiments of the invention disclose a control method and system based on a mobile terminal. The method comprises the following steps: the mobile terminal sending a connection request to an intelligent household center server, and establishing wireless connection; a monitoring pick-up head monitoring a user face image, analyzing an intelligent household device directed by a user line of sight, and sending identification information of the intelligent household device, obtained through analysis to the intelligent household center server; the mobile terminal, according to operation of a user in clicking a preset position of the mobile terminal after pressing a volume adjustment button of the mobile terminal, generating a control command, and sending the control command to the intelligent household center server; and the intelligent household center server, according to the identification information of the intelligent household device, sent by the monitoring pick-up head and the control command sent by the mobile terminal, controlling the corresponding intelligent household device. By use of the method and system provided by the invention, the control convenience of the intelligent household device can be improved.

Owner:SHENZHEN ZHILE TECH LTD CO

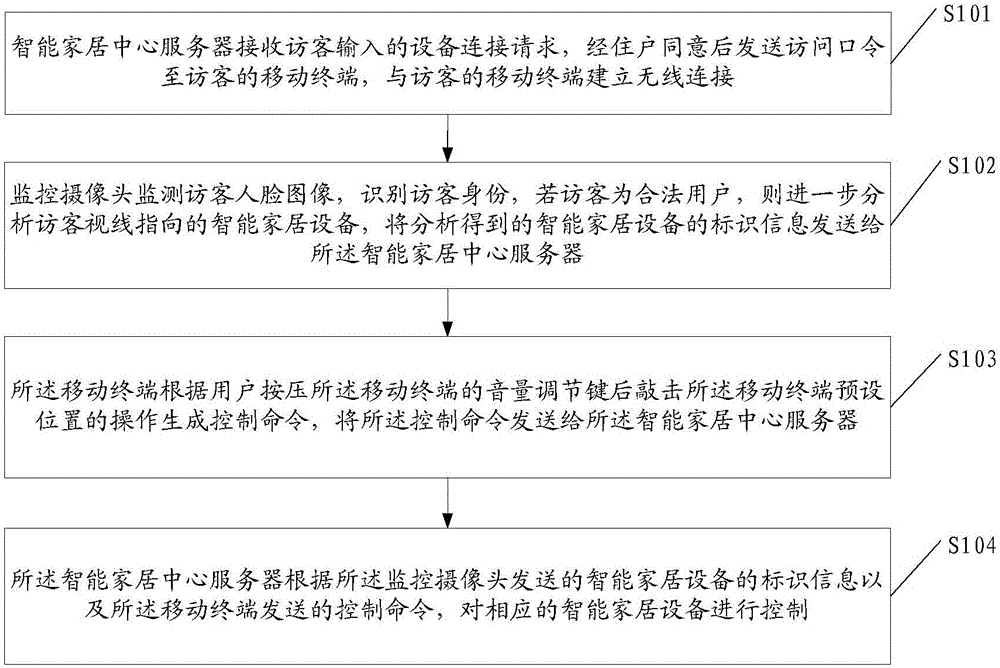

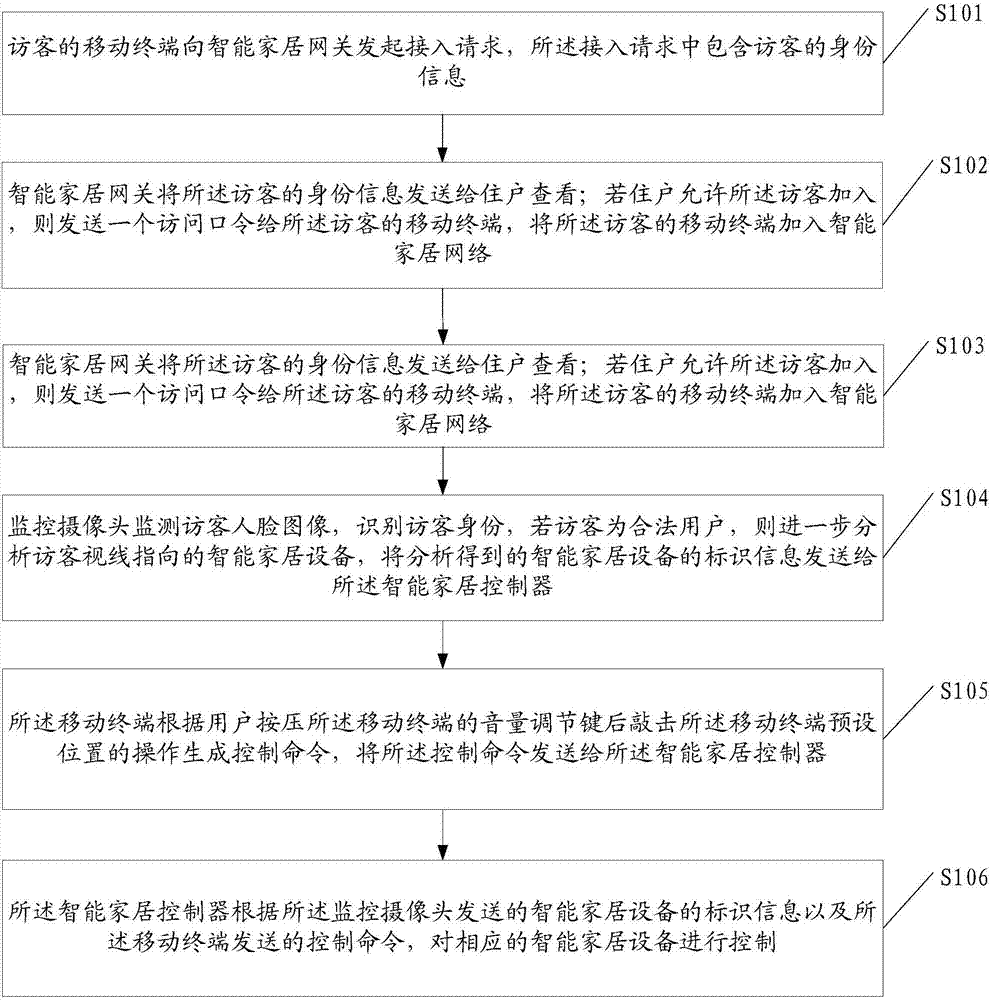

Mobile-terminal-based visitor control method and system

InactiveCN106411672AImprove user experienceWith control functionConnection managementData switching by path configurationSurveillance cameraWireless connectivity

The embodiment of the invention discloses a mobile-terminal-based visitor control method and system. The method comprises: an intelligent household center server receives a device connection request inputted by a visitor, sends an access command to a mobile terminal of the visitor after agreement of a resident, and establishes wireless connection with the mobile terminal of the visitor; a monitoring camera monitors a face image of the visitor and identifies the identity of the visitor; if the visitor is a legal user, an intelligent household device pointed by the visitor eyesight is analyzed and identifier information, obtained by the analysis, of the intelligent household device is sent to the intelligent household center server; the mobile terminal generates a control command according to an operation of pressing a volume adjusting key and then knocking a preset position of the mobile terminal by the user and sends the control command to the intelligent household center server; and the intelligent household center server controls the corresponding intelligent household device based on the identifier information and the control command. Therefore, convenience for controlling an intelligent household device by a visitor is improved.

Owner:SHENZHEN ZHILE TECH LTD CO

Laser double-wire welding technology for aluminum alloy vehicle body part

ActiveCN103639597AEasy to operateLess prone to misuseWelding/soldering/cutting articlesWorkpiece edge portionsControl systemUltimate tensile strength

The invention discloses a laser double-wire welding technology for an aluminum alloy vehicle body part. The laser double-wire welding technology comprises the steps as follows: 1), performing profile assembly; 2), establishing a laser welding tracking program in a welder control system; 3), establishing a double-wire welding technology program in the welder control system; and 4), starting a welder to complete welding. According to the laser double-wire welding technology for the aluminum alloy vehicle body part, a laser welding tracking template is established, and manual welding bead tracking is replaced by laser tracking, so that when the actual welding joint position detected by a laser tracking system and the simulated theoretic welding joint position have deviation, an operator can directly perform on-line compensation according to a deviation value provided by the system, a welding gun is restored to the right position, the operation is simple, further, error operation is not generated easily, the problems that labor intensity for welding gun state observation during manual welding bead tracking is large, operation for on-line welding parameter correction is complicated, operation mistake is easy to generate and the like are solved, and the work efficiency can be greatly improved; and moreover, double-wire welding is adopted, the welding efficiency of the double-wire welding is higher than that of single-wire welding, simultaneously, the welding joint penetration depth is large, and the welding quality is better.

Owner:辽宁忠旺铝合金精深加工有限公司

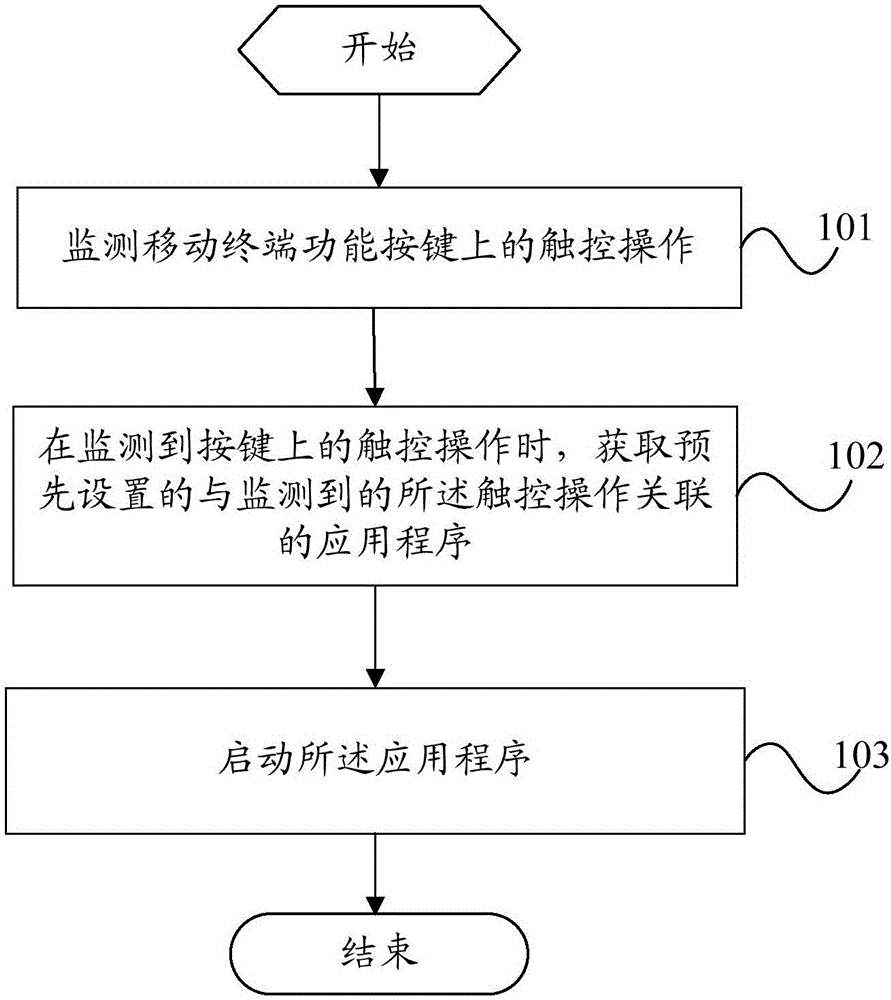

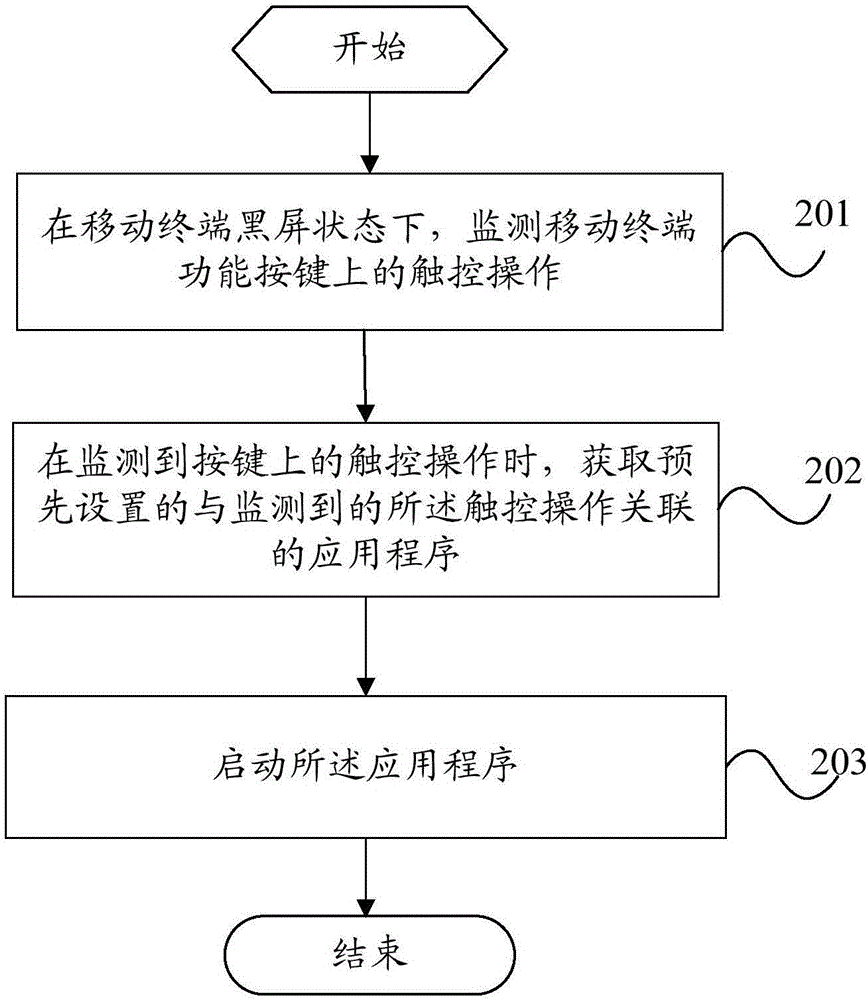

Control method of mobile terminal and mobile terminal

InactiveCN106227453AEasy to operateLess prone to misuseInput/output processes for data processingEmbedded systemComputer science

Owner:VIVO MOBILE COMM CO LTD

Pressing piezoelectric power generation device

InactiveCN109936302AIncrease power generation capacityIncrease power generationPiezoelectric/electrostriction/magnetostriction machinesElectricityKey pressing

The invention relates to the technical field of power generation, in particular to a pressing piezoelectric power generation device. The piezoelectric power generation device of the invention is a triggered piezoelectric power generation device based on pressure change, and operates in the way of a key. In order to make piezoelectric oscillators deform largely to form higher power generating capacity, the piezoelectric oscillators are supported in a mode of simple peripheral support. In view of the characteristics of high voltage and low current of piezoelectric power generation, a plurality of circular piezoelectric films are connected in parallel to obtain an appropriate current and voltage so as to improve the generation power. During use, when the key is pressed with a finger, the piezoelectric oscillators bend and generate electricity to supply power to external electromechanical equipment. The operation is similar to pressing a remote control function button to issue an instruction. The pressing piezoelectric power generation device of the invention is simple to operate and small. As long as the key is pressed slightly, each piezoelectric oscillator can be deformed. The greatest advantage is that the device can be completely sealed, is less prone to wrong operation and is of higher reliability.

Owner:赵富生

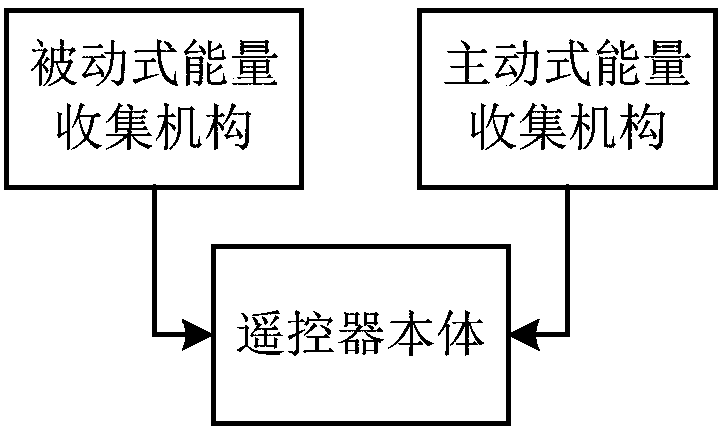

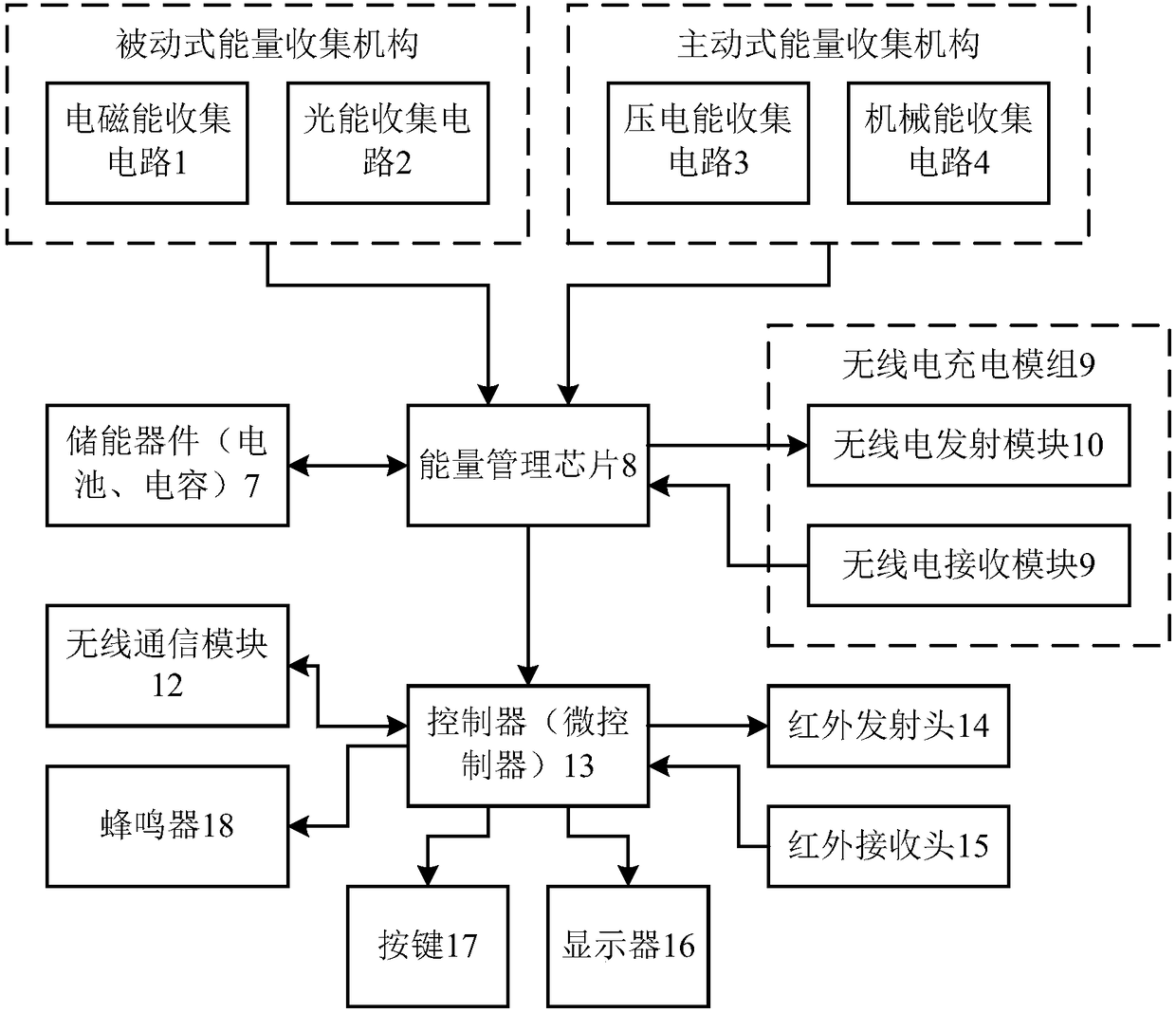

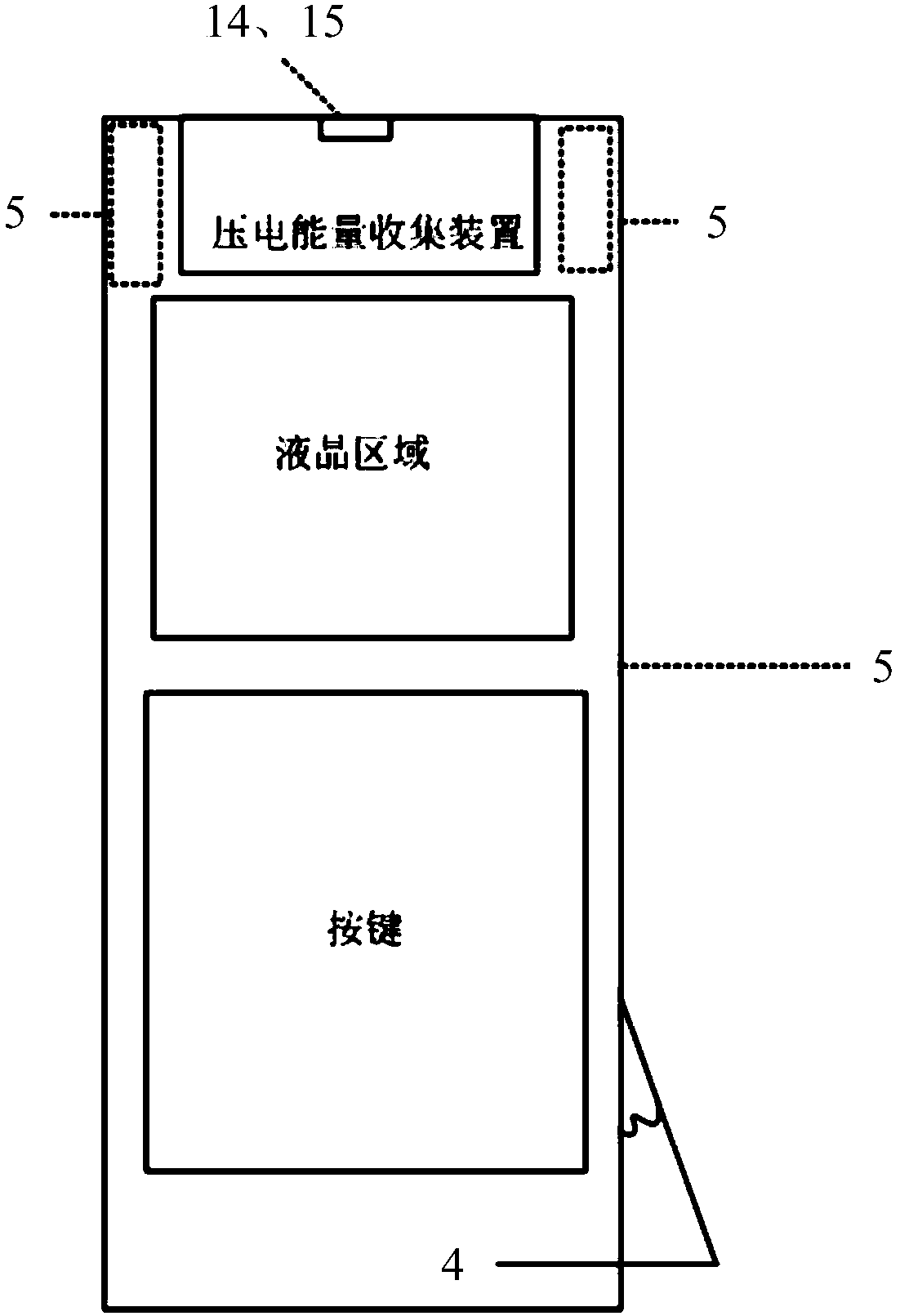

Remote control unit and control method thereof

PendingCN108091125AImprove convenienceOvercome low collectionBatteries circuit arrangementsNon-electrical signal transmission systemsAutomotive engineeringEnergy harvesting

The invention discloses a remote control unit and a control method thereof. The remote control unit comprises a remote control unit body, a passive energy collecting mechanism and an active energy collecting mechanism, wherein the passive energy collecting mechanism is used for collecting first energy in the environment to which the remote control unit belongs and converting the first energy intofirst electric energy; the active energy collecting mechanism is used for collecting second energy generated when the user operates the remote control unit and converting the second energy into secondelectric energy; the remote control unit body is used for realizing the remote control function by taking the first electric energy and / or the second electric energy as a power supply. With adoptionof the scheme, defects of small collection amount, high probability of misoperation, high probability of key failure and the like in the prior art can be overcome, and the beneficial effects of largecollection amount, low probability of misoperation and low probability of key failure are achieved.

Owner:GREE ELECTRIC APPLIANCES INC

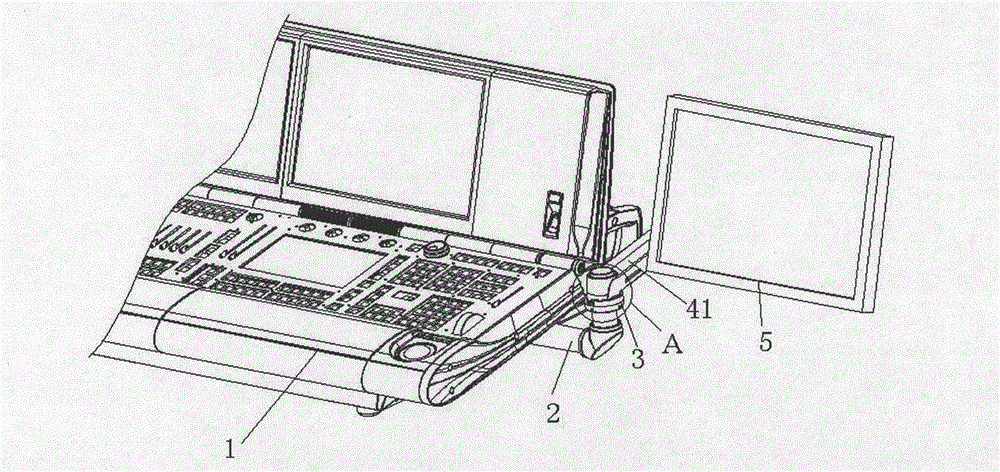

Pan-tilt universal positioning mechanism and light control console employing same

ActiveCN102979812AExpand the scope of activitiesRelieve tension and fatiguePivotal connectionsPosition/direction controlEngineeringLighting control console

The invention discloses a pan-tilt universal positioning mechanism. The pan-tilt universal positioning mechanism comprises a supporting member and a universal rotating mechanism, wherein one end of the universal rotating mechanism is rotatably connected with the supporting member, and the other end of the universal rotating mechanism is fixedly connected with a pan-tilt. The invention further discloses a light control console. According to the pan-tilt universal positioning mechanism and the light control console employing the pan-tilt universal positioning mechanism, the pan-tilt which can rotate and stretch in all directions is arranged based on the existing light control console, so that a lighting engineer can place objects conveniently, and additional display equipment can be provided for the lighting engineer.

Owner:GUANGZHOU FINEART LIGHTING

Visitor control method and system based on mobile terminal

InactiveCN106878273AImprove user experienceWith control functionConnection managementCharacter and pattern recognitionSurveillance cameraComputer terminal

The embodiment of the invention discloses a visitor control method and a system based on a mobile terminal. The method comprises steps: the mobile terminal of a visitor uses the identity information of the visitor to initiate an access request to an intelligent home gateway, and after access is allowed by a resident, the mobile terminal is added to an intelligent home network; wireless connection is built with an intelligent home controller; a monitoring camera monitors the face image of the visitor, the identity of the visitor is recognized, if the visitor is a legal user, an intelligent home device to which the sight line of the visitor points is further analyzed, and the analyzed and obtained identity information of the intelligent home device is transmitted to the intelligent home controller; the mobile terminal generates a control command according to operation that the user presses a volume adjustment key of the mobile terminal and then knocks the preset position of the mobile terminal, and the control command is sent to the intelligent home controller; and the intelligent home controller controls the corresponding intelligent home device according to the identity information and the control command. Thus, the convenience of controlling the intelligent home device by the visitor can be improved.

Owner:SHENZHEN ZHILE TECH LTD CO

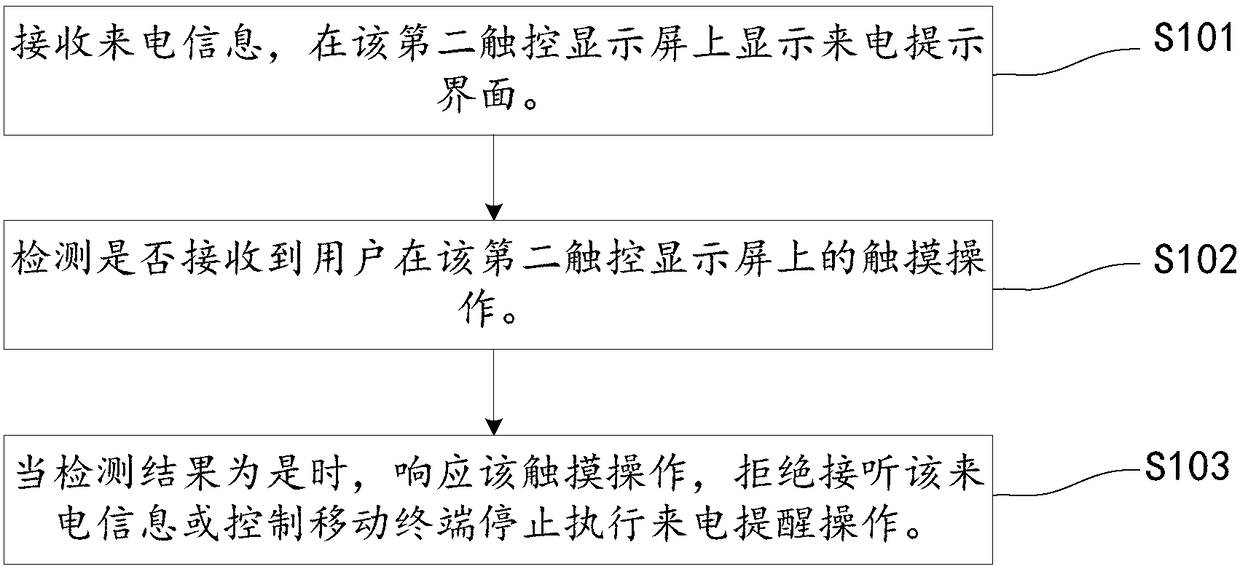

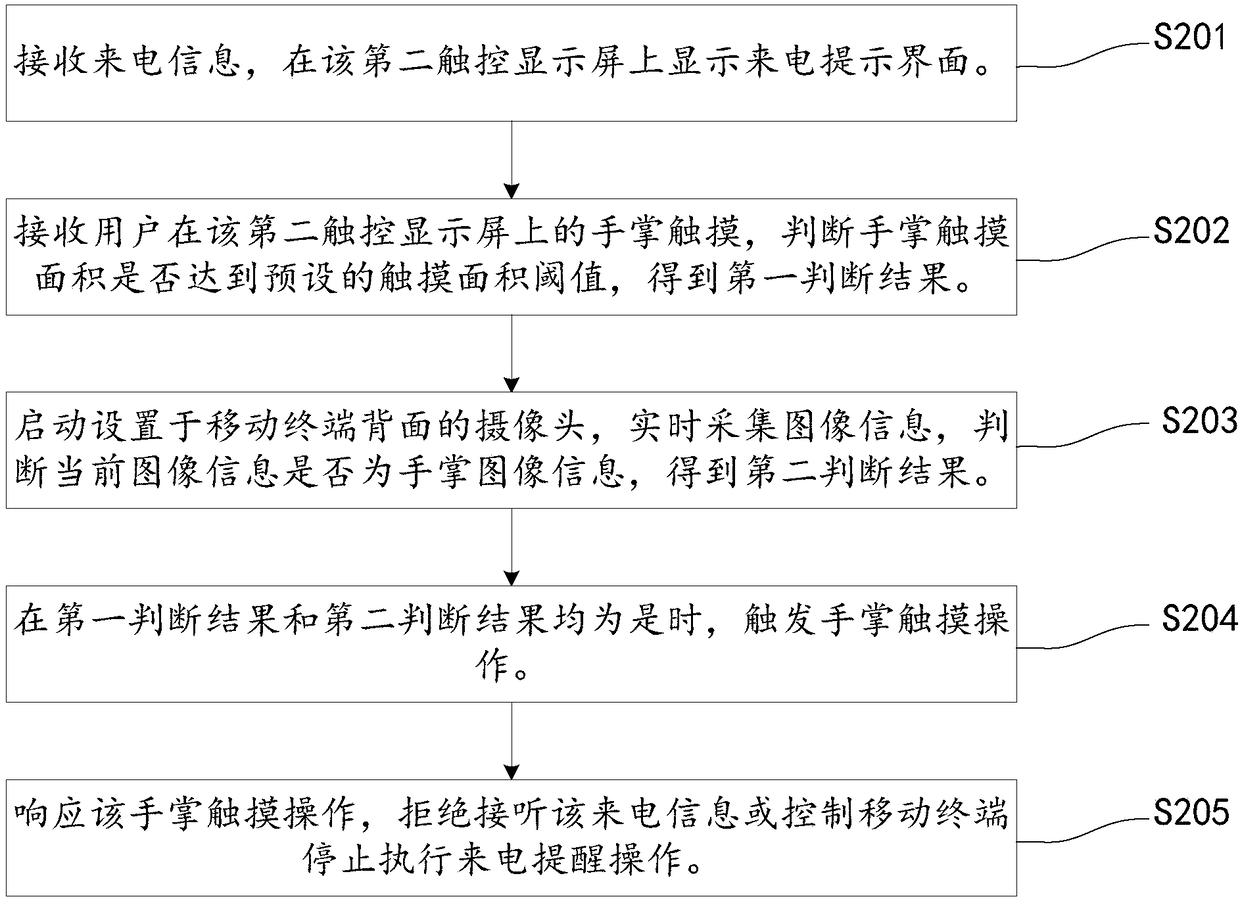

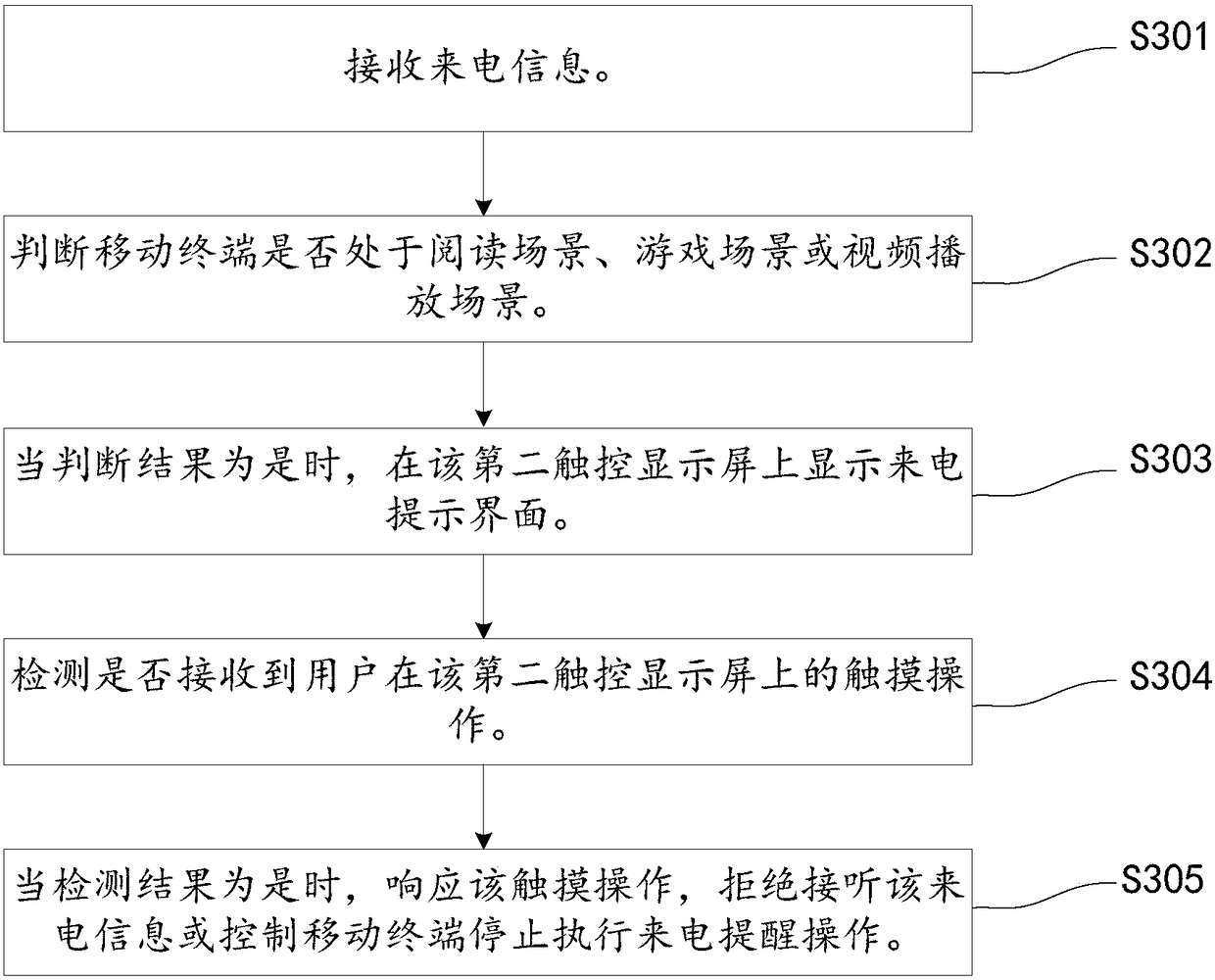

Incoming call processing method, mobile terminal and storage medium

InactiveCN108616645AEasy to operateNot easy to misuseDevices with multiple display unitsDevices with sensorReal-time computingComputer terminal

The present invention belongs to the communications technological field and relates to an incoming call processing method, a mobile terminal and a storage medium. The incoming call processing method includes the following steps that: incoming call information is received, and an incoming call prompting interface is displayed on a second touch control display screen; whether the touch operation ofa user on the second touch control display screen is received is detected; and when a detection result indicates that the touch operation of the user on the second touch control display screen is received, the touch operation is responded, and incoming caller information is refused or a mobile terminal is controlled to stop performing incoming call promoting operation. According to the incoming call processing method of the invention, the incoming caller information is processed through the touch operation on the second touch control display screen at the back surface of the mobile terminal. The incoming call processing method has the advantages of simple operation and little possibility of making wrong operation, and can improve user experience.

Owner:BEIJING ZHUMU LANGMA MOBILE COMM CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com