A resin and sand-based permeable material

A resin and epoxy resin technology, applied in the field of resin and sand-based permeable materials, can solve the problems of low water permeability, poor continuous water permeability, and unsatisfactory weather resistance of sand-based permeable bricks, and achieve good continuous water permeability and antifouling. Strong anti-blocking ability and good water permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

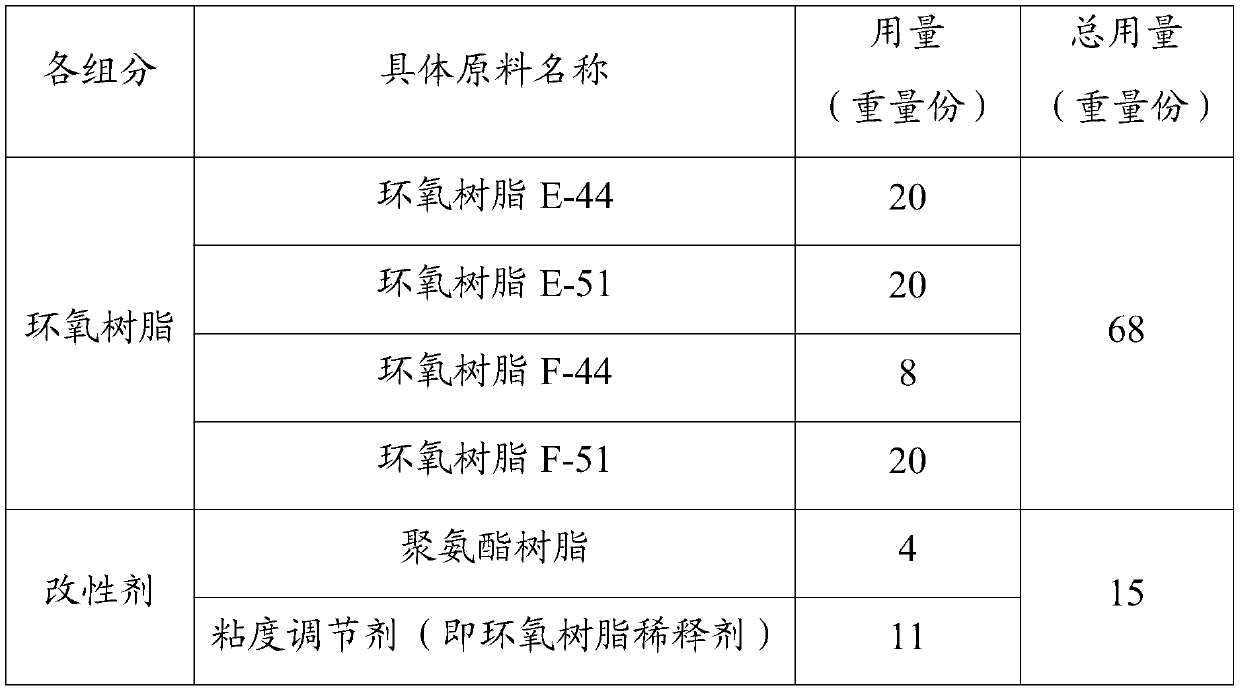

[0026] The resin of this embodiment, the raw materials used for its preparation include the following components: epoxy resin, modifier, light stabilizer, antioxidant, dispersant, micropore generating agent, and catalyst. In parts by weight, the ratio of each component is: 68 parts of epoxy resin, 15 parts of modifier, 0.05 part of light stabilizer, 0.03 part of antioxidant, 0.2 part of dispersant, 10 parts of micropore generator, 0.01 catalyst. Among them, the epoxy resin can be selected from any one of E-44, E-51, F-44 and F-51 or any two or more of them, and the mixing ratio is arbitrary. The components and specific proportions of the above-mentioned raw materials are shown in Table 1.

[0027] Table 1. Components and specific proportions of each raw material

[0028]

[0029]

[0030] Among them, phenolic compounds can choose tert-butyl hydroquinone, eugenol, acetaminophen, tea polyphenols, etc., and amine compounds can choose naphthylamine, diphenylamine, p-phenyl...

Embodiment 2

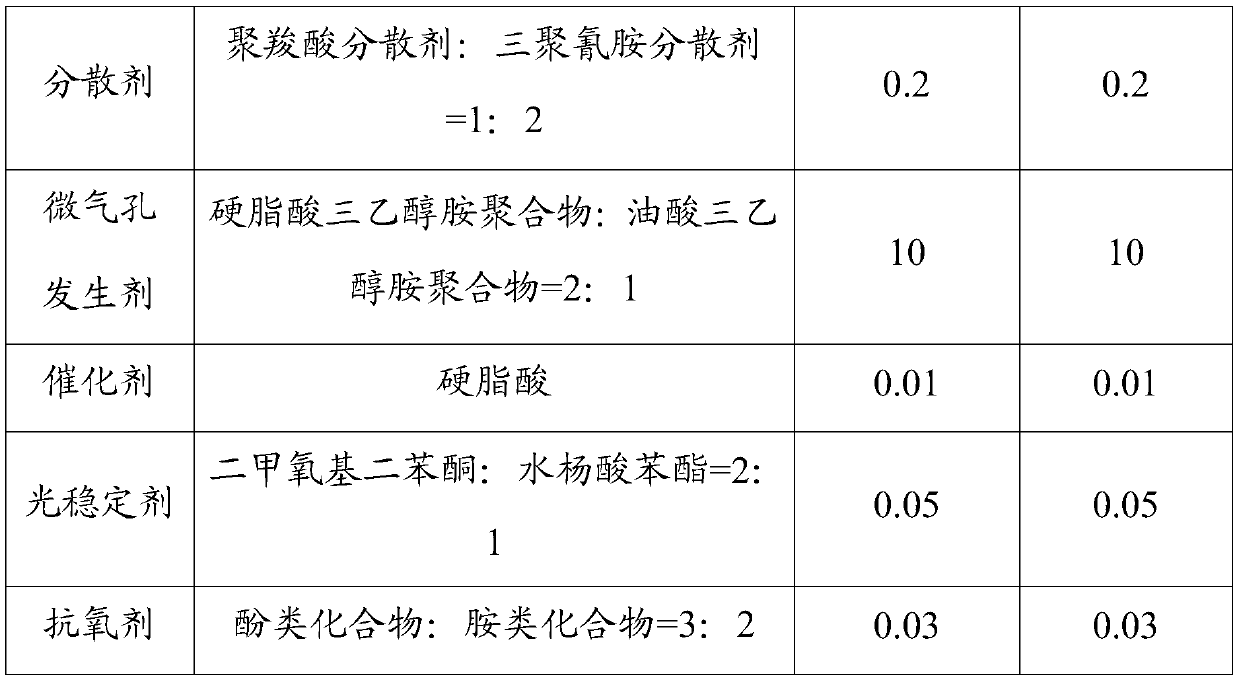

[0037] This example is similar to Example 1, wherein the components and specific ratios of the raw materials used to prepare the resin are shown in Table 2.

[0038] Table 2 The components and specific proportions of each raw material

[0039]

[0040] Among them, phenolic compounds can choose tert-butyl hydroquinone, eugenol, acetaminophen, tea polyphenols, etc., and amine compounds can choose naphthylamine, diphenylamine, p-phenylenediamine, diaryl secondary amine, Ketoamines, aldoamines, etc.

[0041] The preparation method of the resin of this embodiment is: add the epoxy resin, modifier, and catalyst in the proportion described in this embodiment into the reaction kettle, polymerize for 6-7 hours under the environment of 70-85 ° C, and then cool to At room temperature, add a dispersant, a light stabilizer, an antioxidant, and a micropore generating agent and stir evenly to obtain a resin.

Embodiment 3

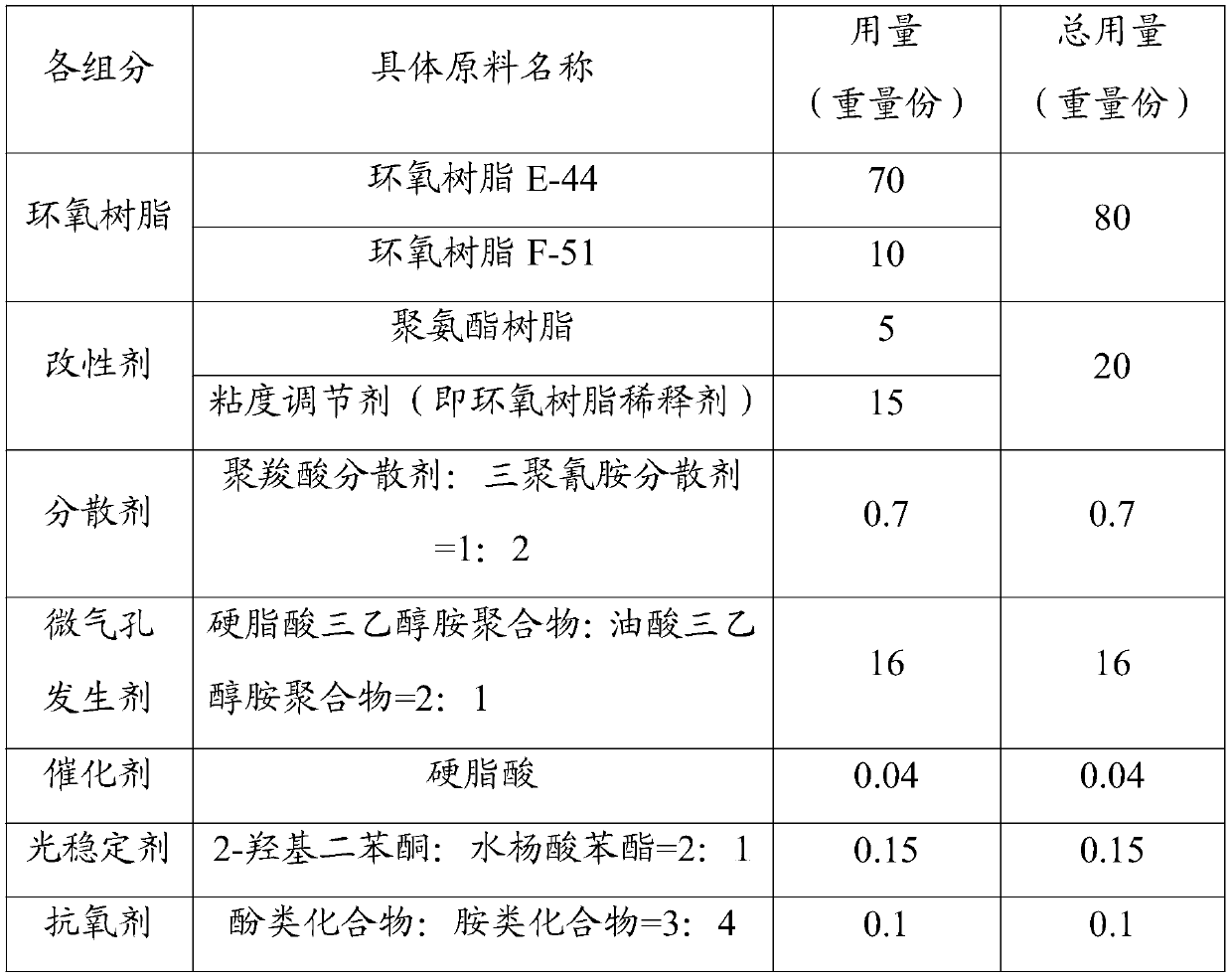

[0043] This example is similar to Example 1, wherein the components and specific ratios of the raw materials used to prepare the resin are shown in Table 3.

[0044] Table 3 The components and specific proportions of each raw material

[0045]

[0046] Among them, phenolic compounds can choose tert-butylhydroquinone, eugenol, acetaminophen, tea polyphenols, etc., and amine compounds can choose naphthylamine, diphenylamine, p-phenylenediamine, diaryl secondary amine, Ketoamines, aldoamines, etc.

[0047] The preparation method of the resin of this embodiment is as follows: adding the epoxy resin, modifying agent, and catalyst into the reaction kettle, polymerizing for 6-7 hours under the environment of 70-85°C, then cooling to room temperature, adding dispersant, The light stabilizer, antioxidant, and micropore generating agent are evenly stirred to obtain the resin.

[0048] According to JG / T 376-2012 and the relevant test and evaluation standards mentioned therein, the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com