Method and device for producing heatproof decoration film

A decorative film and heat-resistant technology, applied in lamination devices, chemical instruments and methods, lamination, etc., can solve the problem that the decorative film cannot obtain heat resistance, achieve heat resistance, ensure product quality, and practicability strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

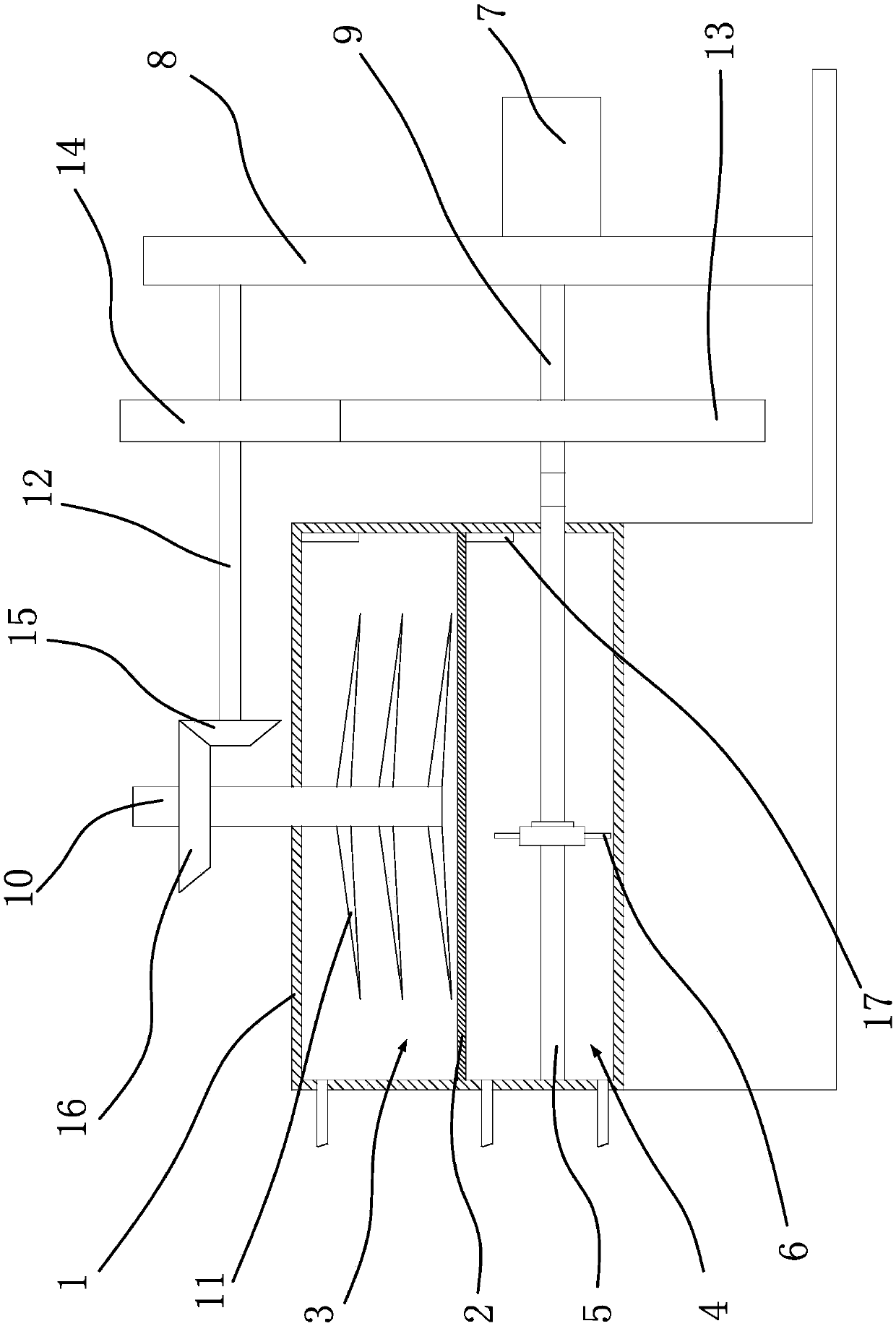

[0042] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

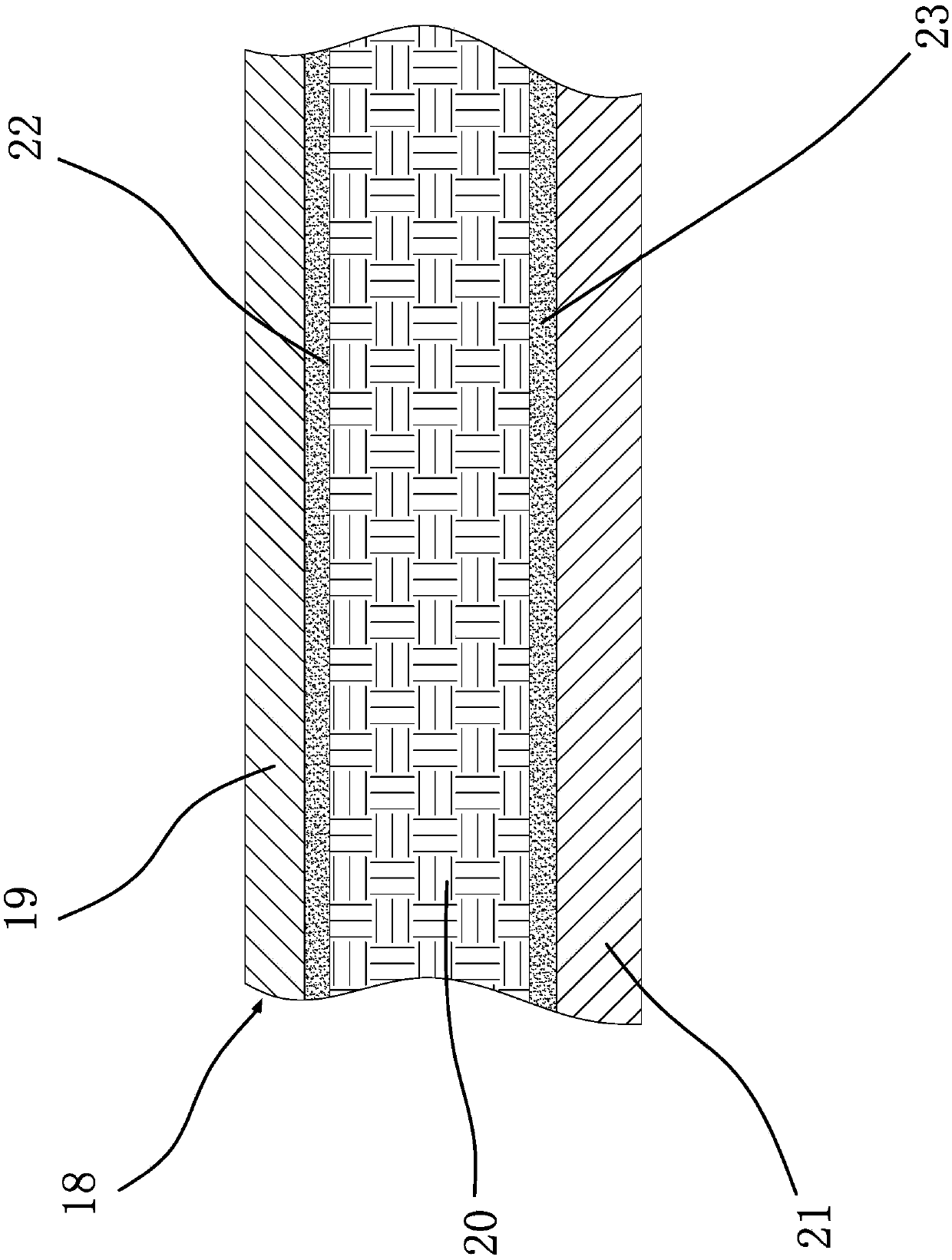

[0043] Such as figure 1 As shown, a method for preparing a heat-resistant decorative film 18 and its device, the heat-resistant decorative film 18 includes a PVC film layer 19, a base cloth layer 20 and a heat-resistant layer 21, and the method for preparing the heat-resistant decorative film 18 includes the following steps:

[0044] a. Put 70 parts of PVC resin, 6 parts of polypropylene fiber, 0.8 parts of diphenyl-isooctyl phosphite, 4 parts of stabilizer, 3 parts of shading powder, 2 parts of polypropylene fiber and 1 part of glass fiber into the mixer Stirring at a rotating speed of 30 rpm, a stirring temperature of 50 degrees, and stirring for 15 minutes to obtain a premixture;

[0045] b. Put 2 parts of flame-retard...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com