A self-propelled trolley for dam breach sealing

A self-propelled platform and breaching technology, which is applied in sea area engineering, construction, water conservancy projects, etc., can solve problems such as difficulty in ensuring personal safety, high labor intensity of manual work, and low efficiency of plugging operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

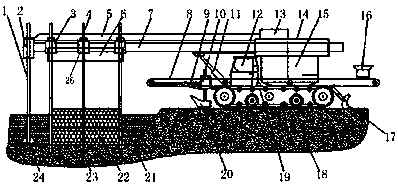

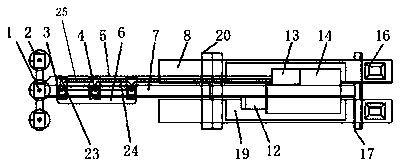

[0016] Refer below figure 1 and figure 2 The technical scheme of the present invention is illustrated in detail.

[0017] Such as figure 1 and figure 2 As shown, a self-propelled trolley for embankment breach sealing of the present invention includes a self-propelled trolley chassis 19, a control room 12, a power output warehouse 15, a hydraulic lifting device 2, a material conveyor 8, a parking ramming machine 10, and a pile rod supply Warehouse 13, gantry arm 5, and arm span control device 14. In the control room 2 on the chassis 19 of the self-propelled trolley, there are operators to control the movement of the trolley and to seal the breach; the power output warehouse 15 has a high-power internal combustion engine or motor Drive the hydraulic pump to output kinetic energy to each working assembly, and install the bicycle trolley chassis 19 rear ends side by side with the pile bar supply warehouse 13.

[0018] The parking ramming machine 10 and the parking device 17 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com