Building external wall waterproof and crack resistant thermal insulation structure

A technology for building exterior walls and waterproof mortar, which is applied to building thermal insulation materials, building components, thermal insulation, etc., can solve problems such as shedding, hidden dangers of water leakage, and multiple cracks, and achieve the effects of improving waterproof performance, simple structure, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

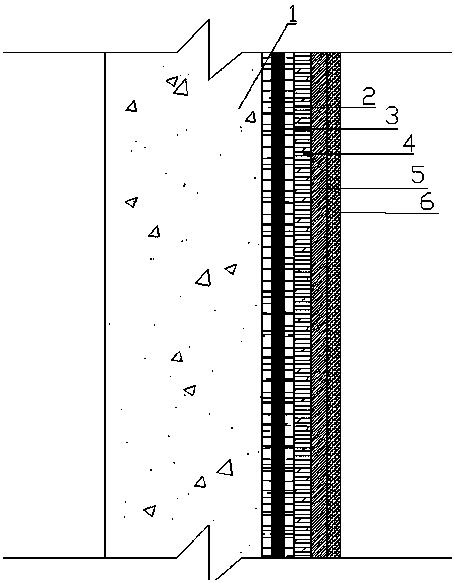

[0019] Embodiment 1: A waterproof and crack-resistant thermal insulation structure for exterior walls of a building, including a wall base 1, on which a polymer waterproof mortar base 2 is arranged, and the polymer waterproof mortar base 2 is far away from the wall base 1 One side of the galvanized steel wire mesh 3 is provided with a polymer waterproof mortar surface layer 4 away from the wall base layer 1, and the polymer waterproof mortar surface layer 4 is far away from the wall base layer 1 There is an insulation layer 5 on one side of the wall, and a polymer waterproof and crack-resistant mortar layer 6 is provided on the side of the insulation layer 5 away from the wall base 1.

[0020] It should be noted that, through the above improvements, the ordinary mortar layer is changed to a polymer waterproof mortar layer, which can improve the waterproof effect, and the anti-crack mortar layer on the insulation layer is changed to a polymer waterproof and anti-crack mortar lay...

Embodiment 2

[0022] Embodiment 2: the sum of the thickness of the polymer waterproof mortar bottom layer 2, galvanized steel wire mesh 3 and polymer waterproof mortar surface layer 4 does not exceed 35 mm; the polymer waterproof mortar bottom layer 2, galvanized steel wire mesh 3 and polymer waterproof When the total thickness of the mortar surface layer 4 exceeds 35 mm, the base of the wall is planted with bars, and then the galvanized steel wire mesh 3 is installed; the galvanized steel wire mesh 3 is a hot-dip galvanized steel wire mesh.

[0023] It should be noted that, through the above improvements, it is possible to effectively avoid the possibility of workers completing the construction of the polymer waterproof mortar layer during the construction process, and at the same time install steel wire mesh to effectively prevent the cracking of the base of the wall; for The polymer waterproof mortar layer over 35mm is further strengthened by installing steel wire mesh after planting bars...

Embodiment 3

[0025] Embodiment 3: The thickness of the polymer waterproof and anti-crack mortar layer 6 is 3-5mm; the construction of the polymer waterproof and anti-crack mortar layer 6 is carried out twice.

[0026] It should be noted that, through the above improvements, the polymer waterproof and anti-cracking mortar layer 6 is constructed twice with a thickness of 3-5 mm, which can effectively avoid the occurrence of cracks caused by one construction.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com