A polymer flooding method for heavy oil reservoirs

An oil displacement method and heavy oil reservoir technology, applied in earthwork drilling, wellbore/well components, production fluids, etc., can solve the problems of large viscosity difference between oil and water phase, small sweep range, and poor polymer flooding effect, etc. Achieve the effects of reducing viscosity ratio, improving mining level and reducing loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

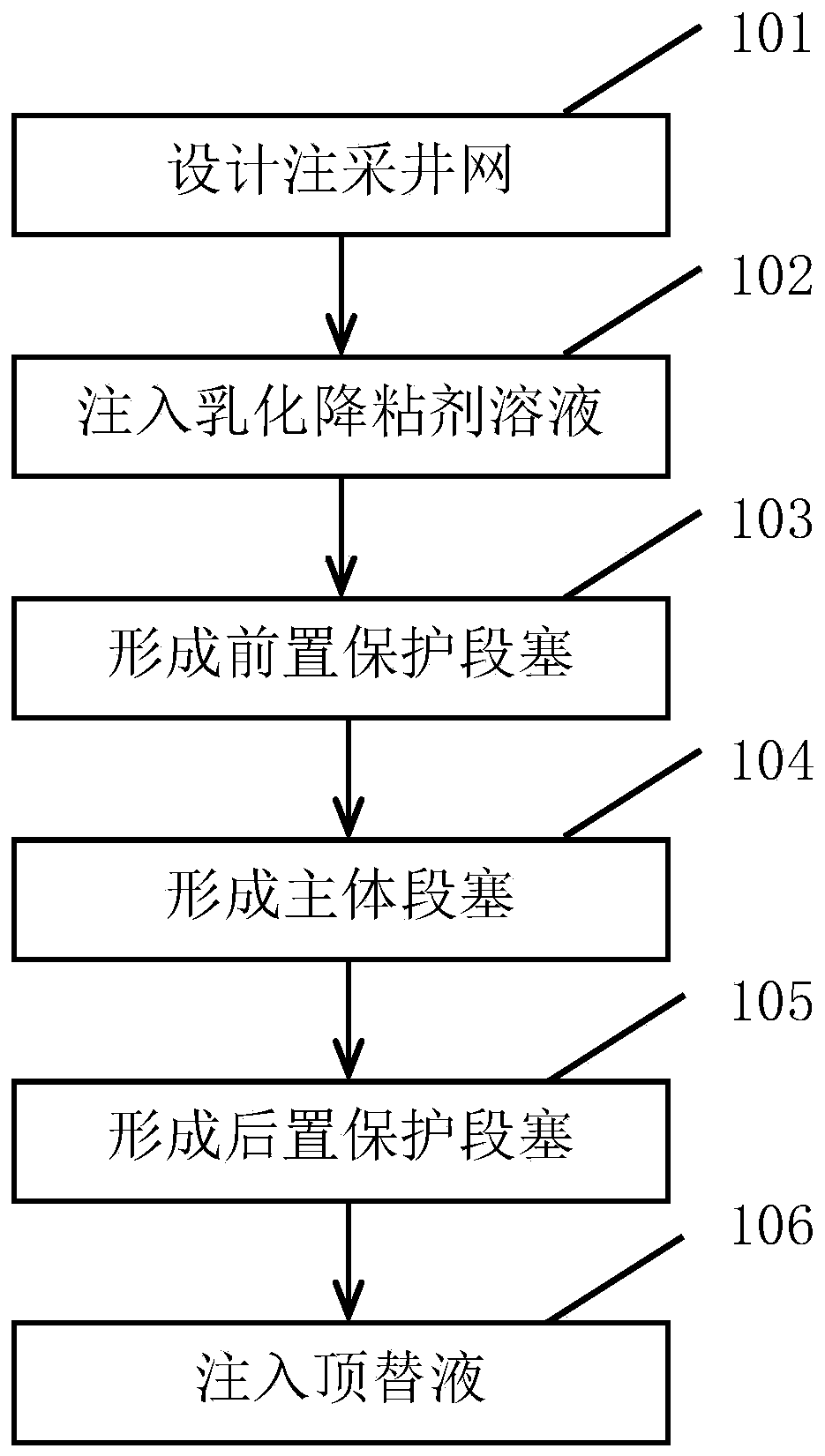

[0032] Such as figure 1 As shown, in step 101, in the target heavy oil reservoir, the central well is selected as a horizontal well, and the corner wells are vertical wells in an inverted 5-point injection-production well pattern, and the horizontal well is used as the injection well, and the vertical well is used as the production well. oil well.

[0033] In step 102, sodium fatty alcohol polyoxyethylene ether sulfonate (produced by Shouguang Luke Chemical Co., Ltd.) is dissolved in water to be configured as an emulsified viscosity reducer solution with a concentration of 1000mg / L, and The injection rate is continuously injected into the wellbore of the horizontal well, and the injection volume is 0.2PV.

[0034] In step 103, dimethyl hexadecyl allyl ammonium chloride / acrylamide copolymer is dissolved in water to form a polymer solution with a concentration of 1400 mg / L and a viscosity of 54 mPa·s, and after emulsification After the injection of the viscosity reducer solution...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com