Gas spring device driven by linear motor

A linear motor and gas spring technology, applied in the field of springs, can solve the problems of limitation of the electric drive mechanism of the tailgate, unstable operation, large equipment volume, etc., and achieve the effects of low manufacturing difficulty, wide application range and fast response speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

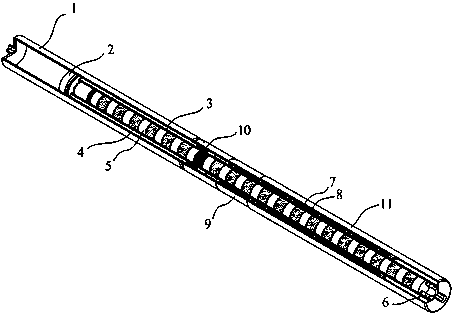

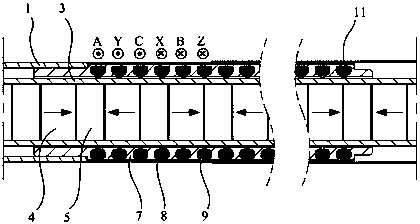

[0035] like figure 1 Shown is a schematic structural view of an embodiment of a gas spring device driven by a linear motor in the present invention. The gas spring device driven by the linear motor of the present embodiment comprises a cylinder liner with an open end, the cylinder liner is provided with a connecting rod 3 which fits with the gap and is made of non-magnetic material, and one end of the connecting rod 3 extends out of the cylinder liner. Outside the opening, a central through hole is provided in the connecting rod 3, and a magnetic force unit is set in the central through hole. The magnetic force unit includes magnets 4 and magnetizers 5 arranged at intervals. One end of the connecting rod 3 located in the cylinder liner is fixedly connected with the piston 2 provided, and the end of the connecting rod 3 extending out of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com