A plastic beating processing device capable of preventing sticking and sticking materials

A processing device and a plastic-capable technology, which is applied in the field of plastic-beating processing devices, can solve the problems of dangerous construction work surfaces, lack of overall guarantee of construction quality uniformity, slow construction speed, etc., and achieve the effect of improving construction quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

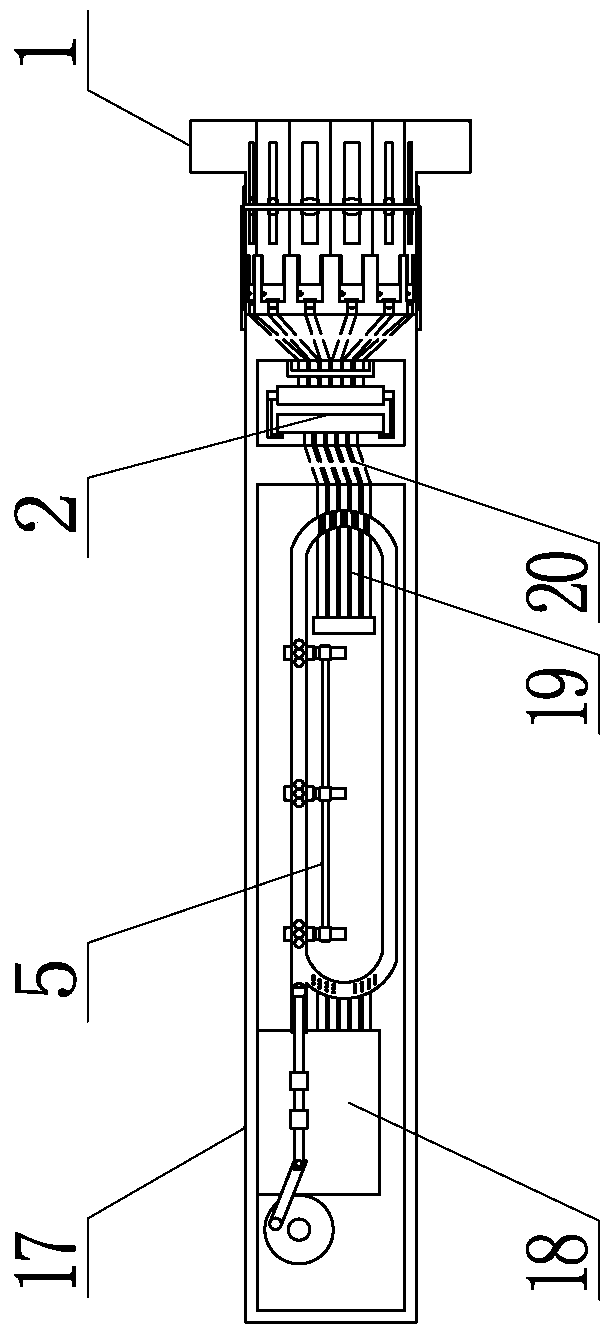

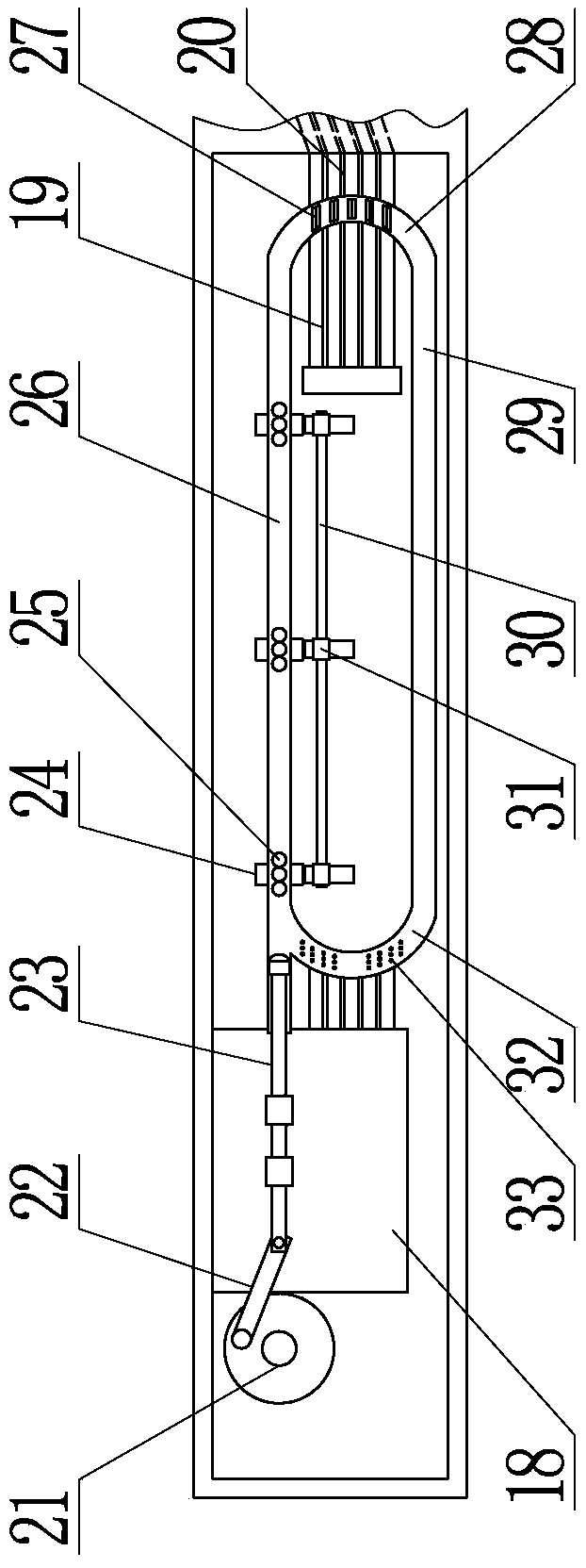

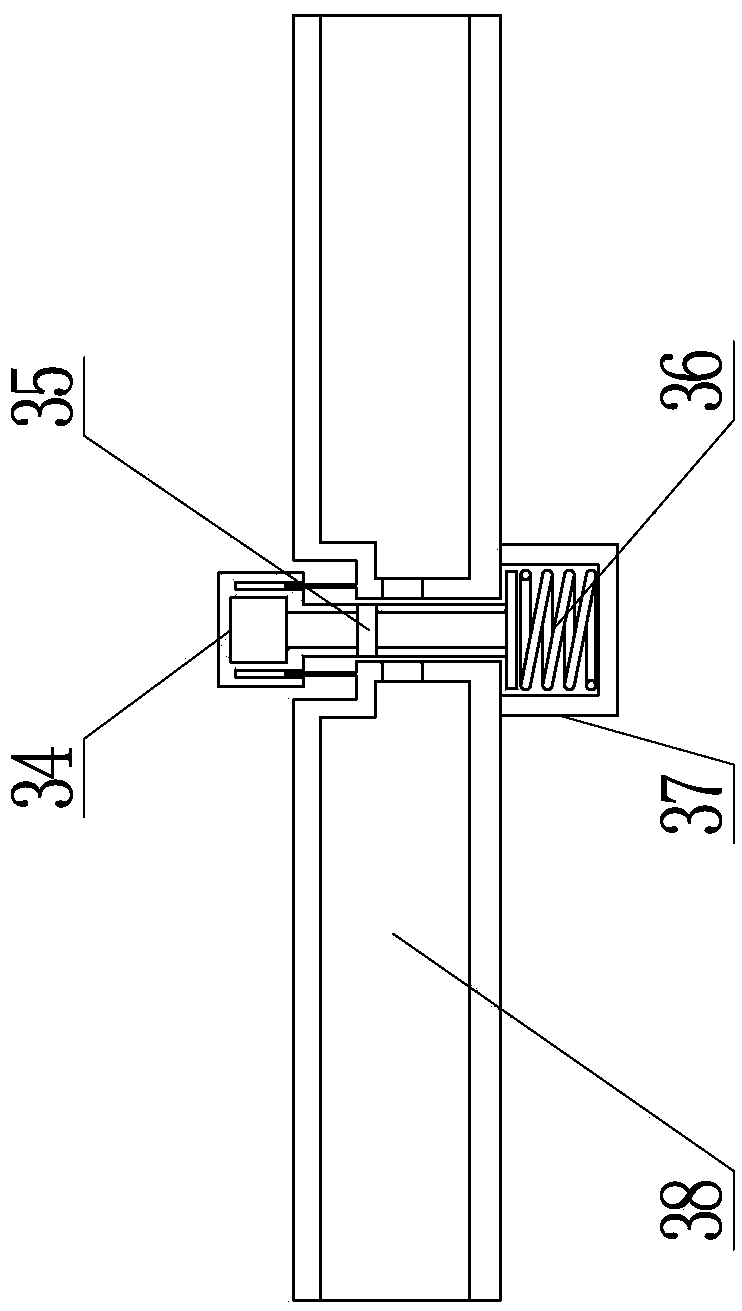

[0026] like figure 1 As shown, a plastic beating processing device capable of preventing adhesion and staining includes two parts, a hammer shaft and a hammer head. The hammer shaft drives the hammer head to act on the refractory plastic surface. A gas storage tank and a pulse gas transmission device are installed in the hammer shaft, three straight slots are set on the hammer head, and the slider is fixed in the straight slots; a slide hammer is set in the straight slot, and a limit position is set on the slide hammer In the chute, the slide block is arranged in the limit chute, and the slide block slides along the straight slot and the limit chute. When the slide hammer is inserted into the straight slot, there is a gas space between the insertion end of the slide hammer and the straight slot. When the slide hammer moves into the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com