Intermediate frequency furnace axial flow pipeline air mixing pressurizing nozzle

An intermediate frequency furnace, axial flow technology, applied in the furnace, crucible furnace, furnace type and other directions, can solve the problem of limited air flow rate, and achieve the effect of improving heating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

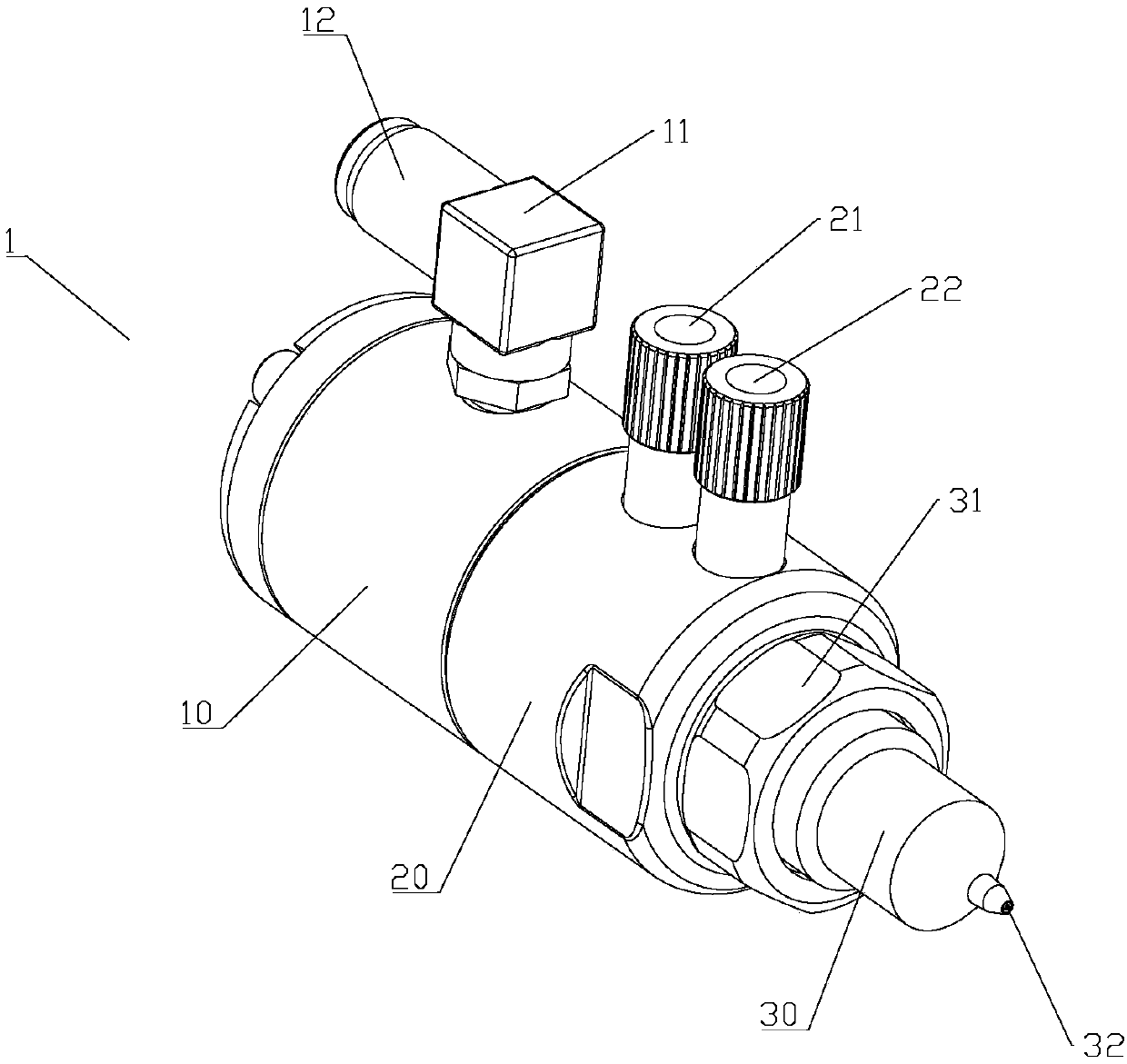

[0012] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

[0013] Such as figure 1 As shown, an intermediate frequency furnace axial flow pipeline air mixing booster nozzle 1 includes a first booster cylinder 10, the first booster cylinder 10 is connected with a second booster cylinder 20, the first booster cylinder 10 is provided with a one-way valve 11, the one-way valve 11 is provided with a high-pressure air inlet 12, and the second booster cylinder 20 is provided with a first control valve stem 21 and a second control valve stem 22, and the first control valve stem 21 controls the flow rate between the first booster cylinder 10 and the second booster cylinder 20, the second control valve rod 22 cont...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap