Flue section matrix type real-time synchronous on-line sampling analysis device and sampling method thereof

A real-time synchronization, sampling and analysis technology, applied in sampling devices and other directions, can solve problems such as unfavorable ultra-low emission, efficient and stable economic operation, inability to effectively reflect distribution, uneven concentration field distribution, etc., to ensure efficient, economical and stable operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

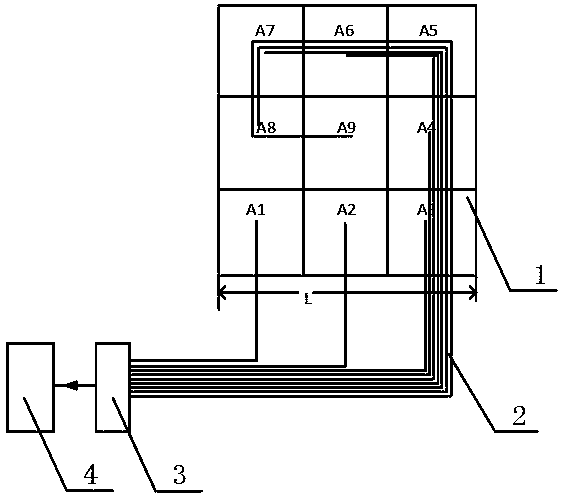

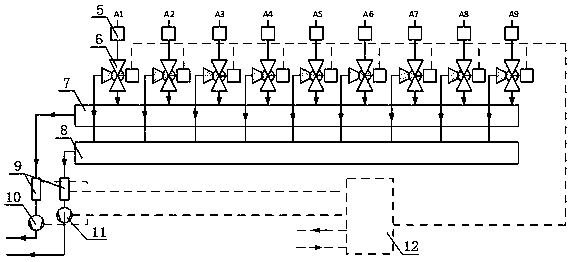

[0046] see Figure 1 to Figure 2 .

[0047] In this embodiment, the sample analysis time of the flue gas analyzer 4 is Δt=20s, the flue gas sampling flow rate in the sampling pipe 2 is v=0.05m / s, and the cross-sectional size of the flue 1 is 6m×6m (length×width). no 1 =2, the length direction of the grid division is L / (n 1 ·The rounded value l of Δt·v) 长 , that is, the rounded value l of 6 / (2·20·0.05) 长 =3, the width direction of grid division is M / (n 1 ·The rounded value m of Δt·v) 宽 , that is, the rounded value of 6 / (2·20·0.05) is m 宽 =3, where n 1 is 2, so that the mesh number of the section of flue 1 is determined to be l 长 × m 宽 =3×3.

[0048] Correspondingly, the number of sampling tubes 2 is nine, and the length difference between adjacent sampling tubes 2 is n 1 ·Δt·v=2·20·0.05=2m.

[0049] That is, the nine sampling tubes 2 are No. 1 sampling tube, No. 2 sampling tube, No. 3 sampling tube, No. 4 sampling tube, No. 5 sampling tube, No. 6 sampling tube, No. ...

Embodiment 2

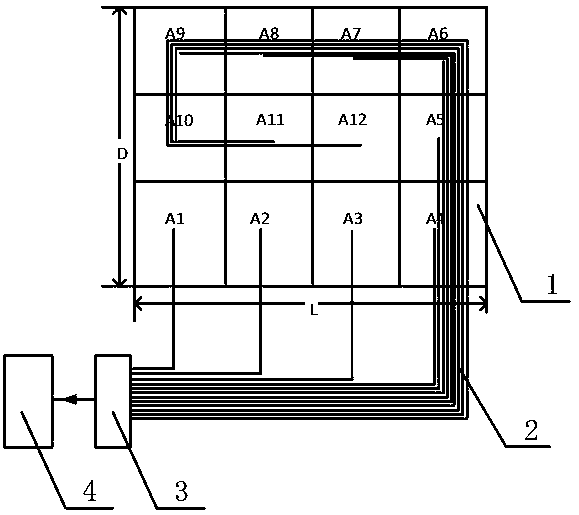

[0057] see Figure 3 to Figure 4 .

[0058] In this embodiment, the sample analysis time of the flue gas analyzer 4 is Δt=40s, the flue gas sampling flow rate in the sampling pipe 2 is v=0.05m / s, and the cross-sectional size of the flue 1 is 8m×6m (length×width). no 1 =1, the length direction of the grid division is L / (n 1 ·The rounded value l of Δt·v) 长 , that is, the rounded value l of 8 / (1·40·0.05) 长 =4, the width direction of grid division is M / (n 1 ·The rounded value m of Δt·v) 宽 , that is, the rounded value of 6 / (1·40·0.05) is m 宽 =3, so that the mesh number of the section of flue 1 is determined to be l 长 × m 宽 =4×3.

[0059] Correspondingly, the number of sampling tubes 2 is twelve, and the length difference between adjacent sampling tubes 2 is n 1 ·Δt·v=1·40·0.05=2m.

[0060] That is, the twelve sampling tubes 2 are No. 1 sampling tube, No. 2 sampling tube, No. 3 sampling tube, No. 4 sampling tube, No. 5 sampling tube, No. 6 sampling tube, No. 7 sampling tu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com