Composite thermoplastic polymers based on reaction with biorenewable oils

A technology of thermoplastic polymers and polymers, which can be applied in the direction of on-site paved concrete pavement, building construction, roads, etc., and can solve problems such as performance enhancement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

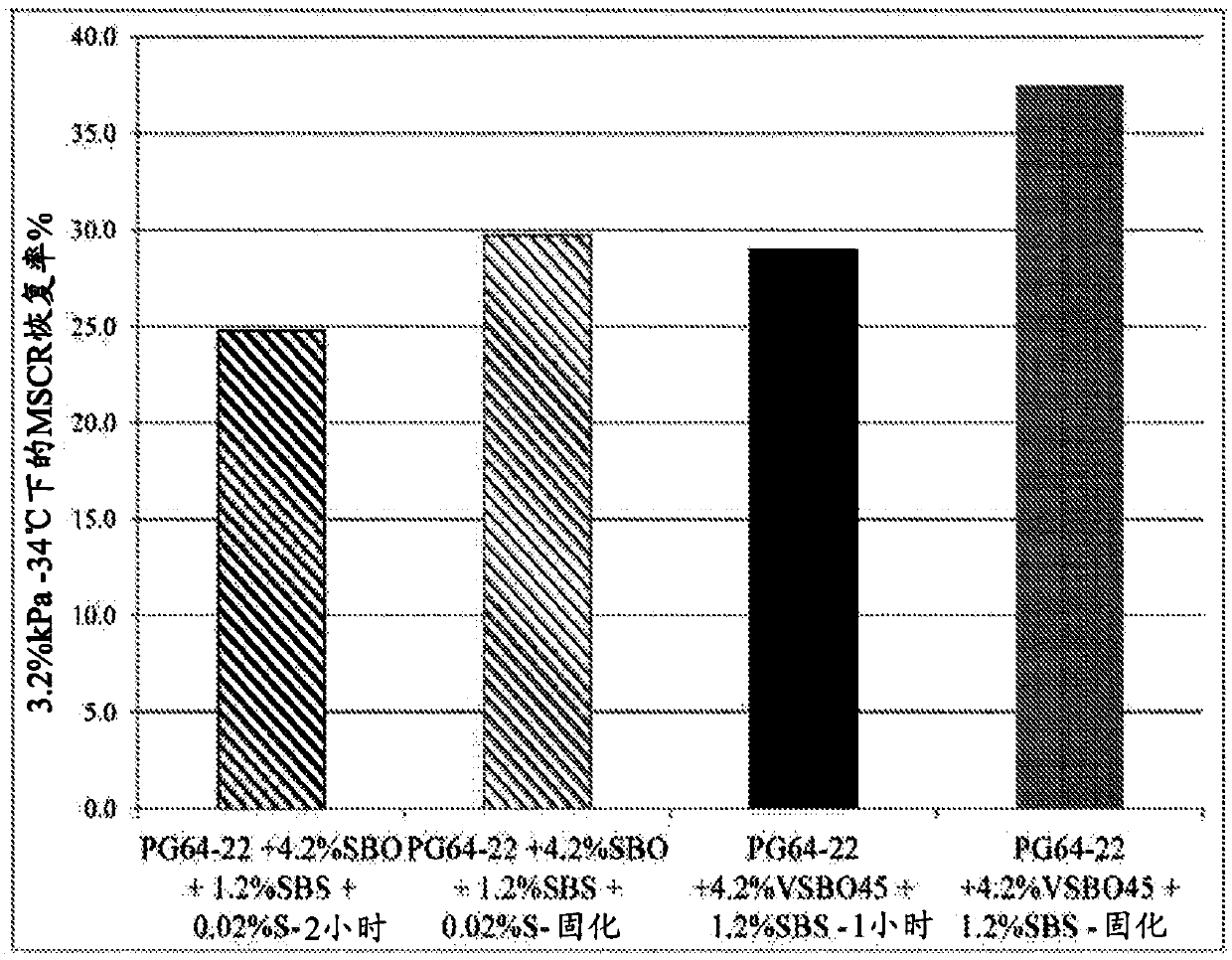

[0078] Example 1: Use of sulfurized vegetable-based oils as polymer compatibilizers and crosslinkers

[0079] Two polymer-modified asphalt blends were compared: one in which elemental sulfur was added directly to the asphalt to crosslink the SBS (blend A) after the conventional asphalt polymer modification procedure, and the other in which A sulfurized vegetable-based oil without crosslinker was added to the bitumen prior to SBS (blend B).

[0080] The Multiple Stress Creep and Recovery procedure under AASHTO T350 is a procedure designed to measure the elasticity of asphalt binders by repeating the 1-second creep and 9-second recovery steps. This procedure is particularly useful for evaluating the performance of polymer-modified asphalts. Using the strain responses from the creep and recovery steps, percent recovery (R%) was calculated as a measure of the ratio of recoverable strain during the 9 second recovery period to the total strain applied at the end of the 1 second c...

Embodiment 2

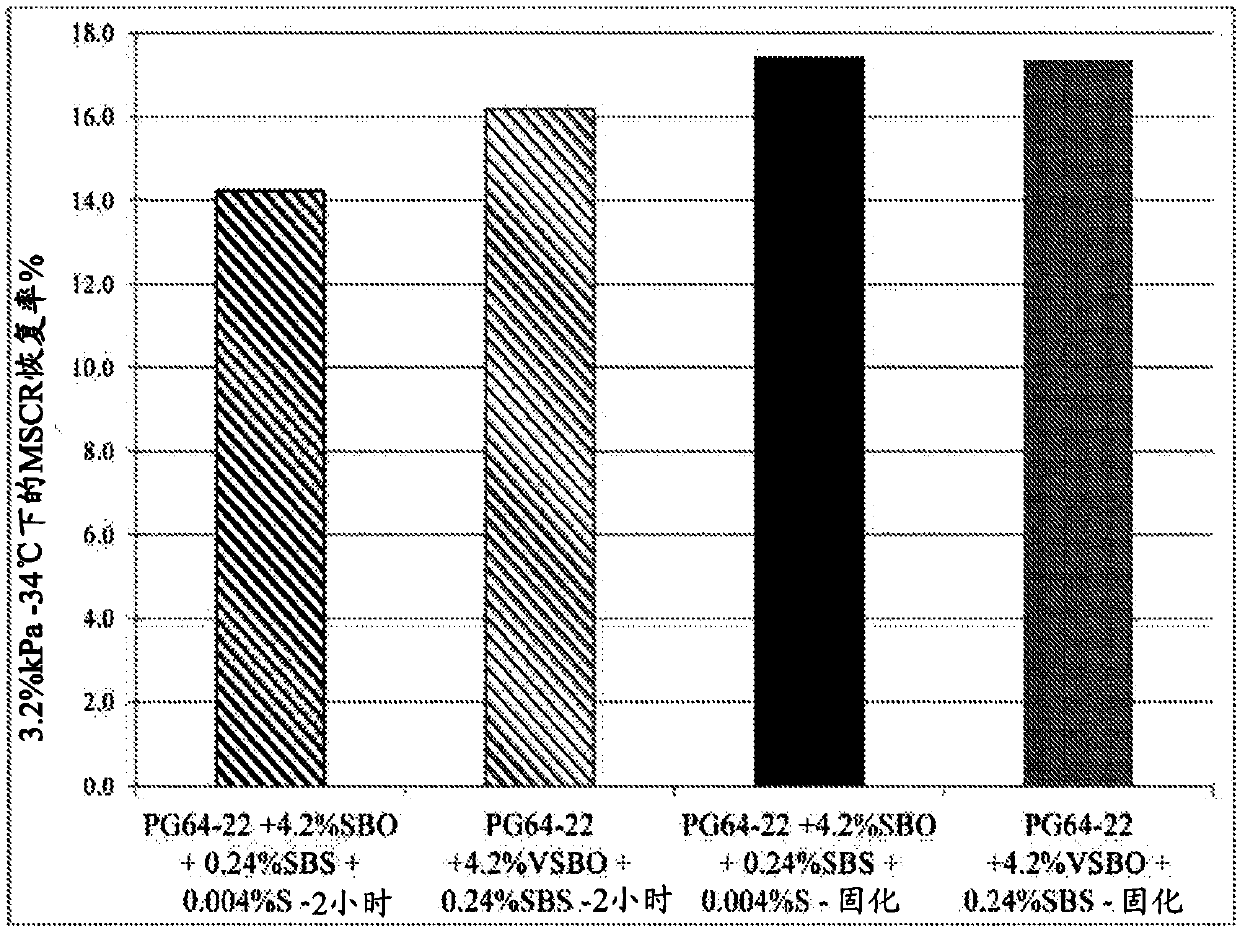

[0104] Example 2: Use of sulfurized vegetable-based oils as polymer compatibilizers and crosslinkers:

[0105] Two polymer-modified asphalt blends were compared: one in which elemental sulfur was added directly to the asphalt to crosslink the SBS (blend A) after the conventional asphalt polymer modification procedure, and the other in which A sulfurized vegetable-based oil without crosslinker was added to the bitumen prior to the polymer (blend B).

[0106] Blend A is a modified asphalt binder comprising:

[0107] • 95.56% pure asphalt binder graded PG64-22 (PG 65.7-24.9) by weight of the blend.

[0108] • 4.2% refined soybean oil by weight of the blend.

[0109] • 0.24% styrene-butadiene styrene (Kraton D-1192) by weight of the blend.

[0110] • 0.004% elemental sulfur by weight of the blend.

[0111] Blend B is a modified asphalt binder comprising:

[0112] • 95.56% pure asphalt binder graded PG64-22 (PG 65.7-24.9) by weight of the blend.

[0113] • 4.2% sulfurized r...

Embodiment 3

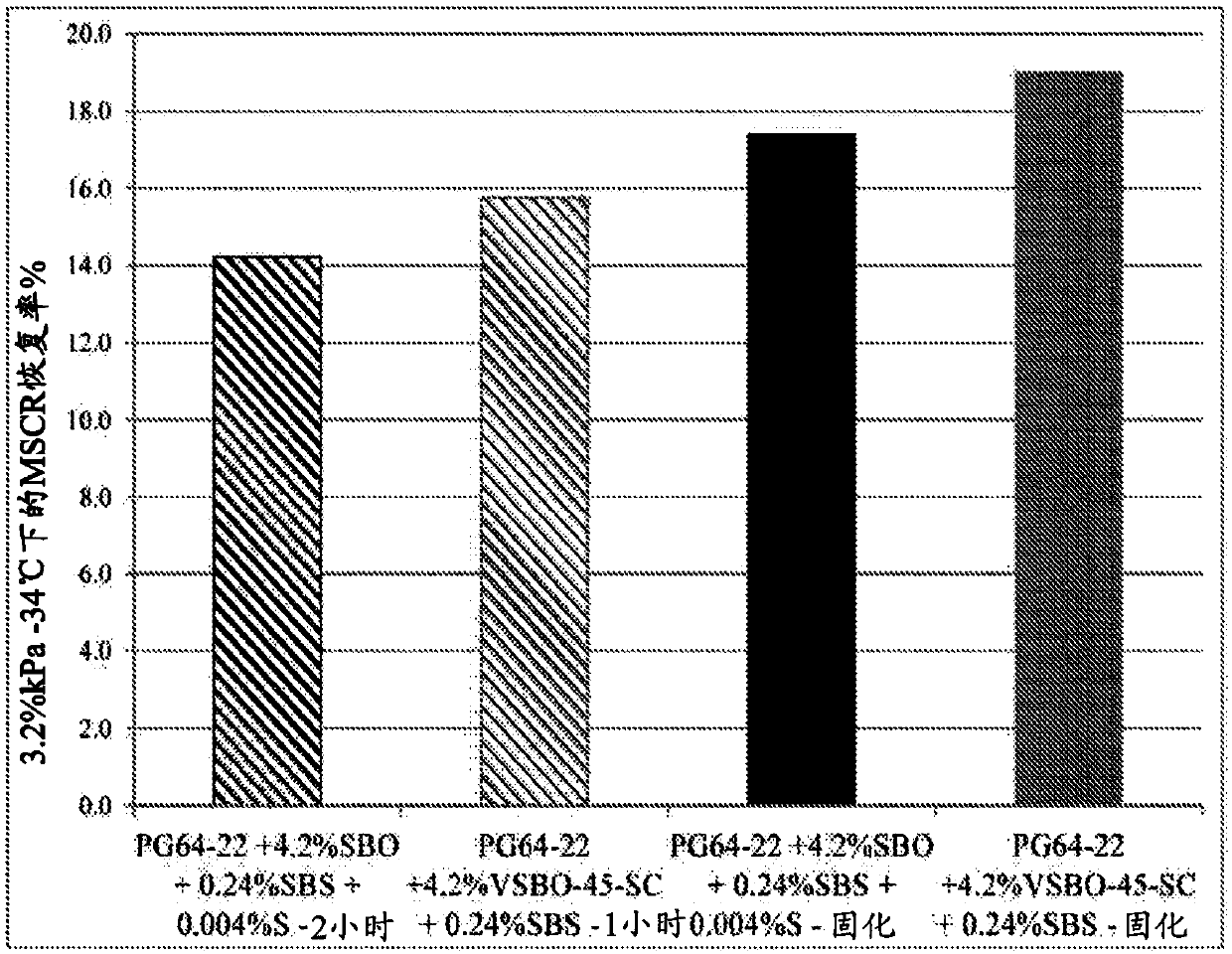

[0125] Example 3: Use of sulfurized vegetable-based oils as polymer compatibilizers and crosslinkers:

[0126] Two polymer-modified asphalt blends were compared: one in which elemental sulfur was added directly to the asphalt to crosslink the SBS (blend A) after the conventional asphalt polymer modification procedure, and the other in which A sulfurized vegetable-based oil without crosslinker was added to the bitumen prior to the polymer (blend B).

[0127] Blend A is a modified asphalt binder comprising:

[0128] • 95.56% pure asphalt binder graded PG64-22 (PG 65.7-24.9) by weight of the blend.

[0129] • 4.2% refined soybean oil by weight of the blend.

[0130] • 0.24% styrene-butadiene styrene (Kraton D-1192) by weight of the blend.

[0131] • 0.004% elemental sulfur by weight of the blend.

[0132] Blend B is a modified asphalt binder comprising:

[0133] • 95.56% pure asphalt binder graded PG64-22 (PG 65.7-24.9) by weight of the blend.

[0134] 4.2% polymeric vege...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

| Acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com