Nut cleaning equipment

A technology for cleaning equipment and nuts, applied in cleaning methods and utensils, cleaning methods using tools, cleaning methods using liquids, etc., can solve problems affecting product quality, high cost, and low cleanliness pass rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

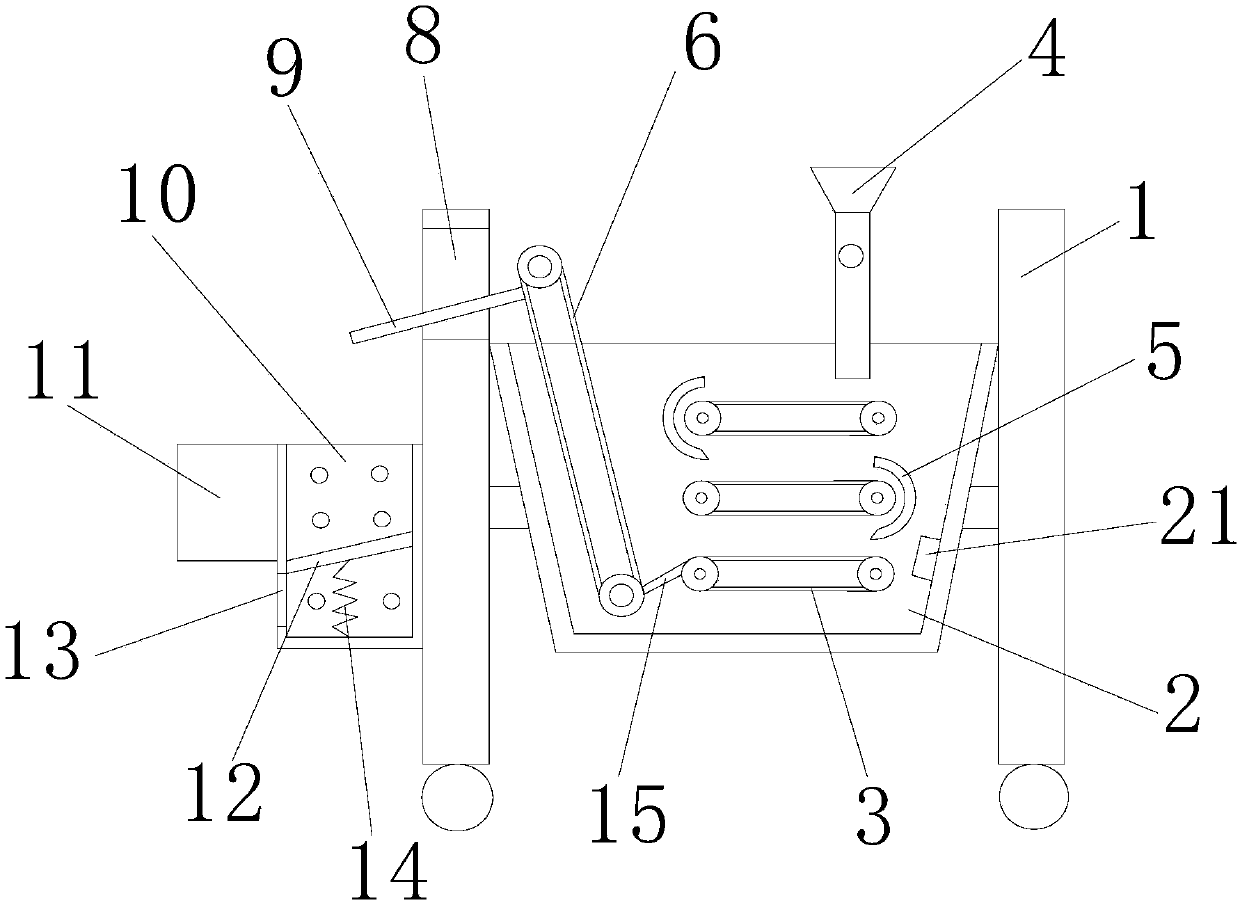

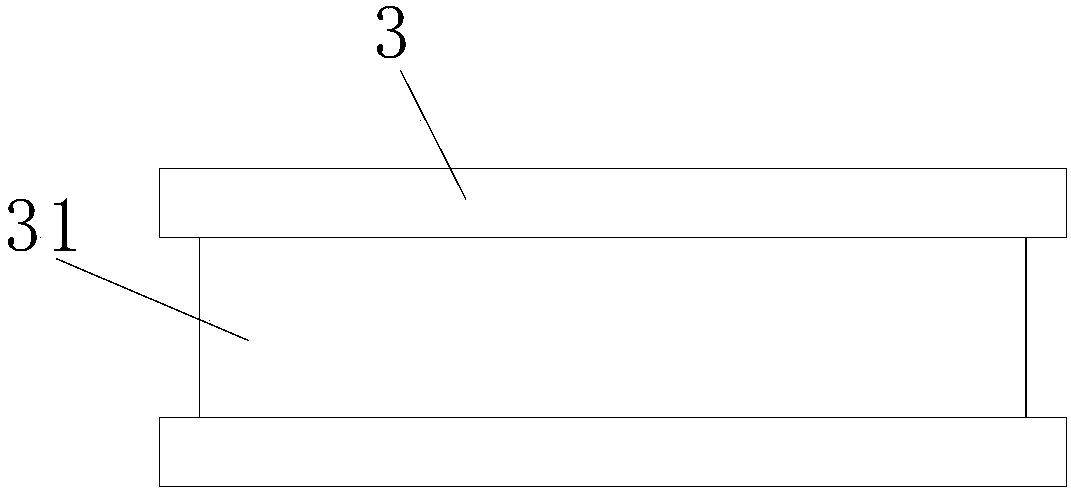

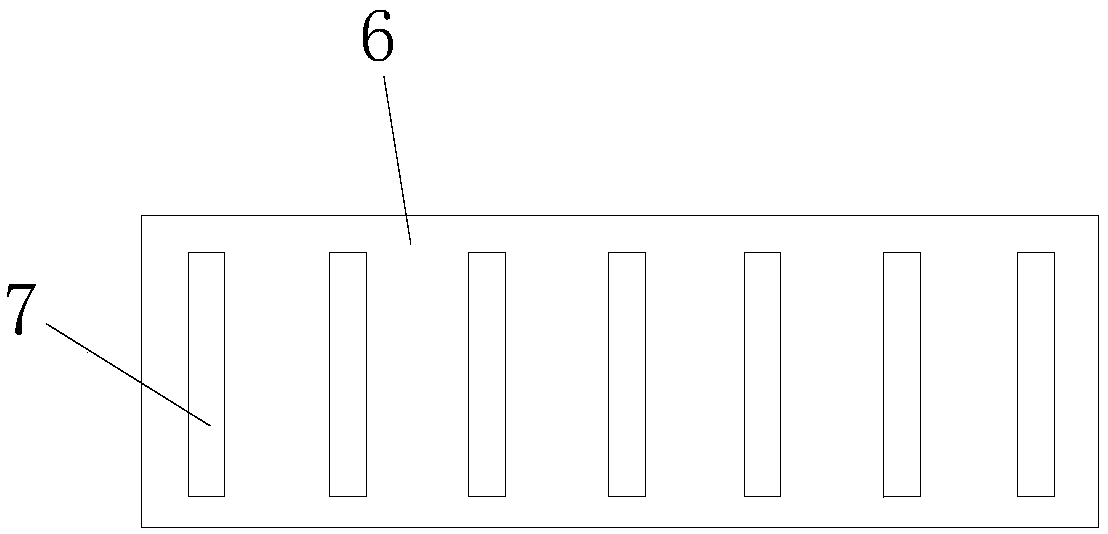

[0020] refer to figure 1 , 2 , 3, a kind of nut cleaning equipment of the present invention, comprises frame 1, cleaning tank 2, first conveyor belt 3, lower hopper 4, arc-shaped baffle plate 5, second conveyor belt 6, magnet block 7, discharge port 8, outlet Material plate 9, material receiving box 10, hot air blower 11, backing plate 12, blanking opening 13, spring 14 and slide plate 15, described frame 1 is fixedly provided with cleaning tank 2, in described cleaning tank 2, from top to bottom There are several horizontally arranged first conveyor belts 3 below, and the rotation directions of the first conveyor belts 3 adjacent up and down are opposite, and a lower hopper 4 is provided directly above the input end of the first conveyor belt 3 on the top. The lower hopper 4 is fixedly connected to the frame 1, and the output end of the first conveyor belt 3 above the bottommost conveyor belt 3 is provided with an arc-shaped baffle plate 5 fixedly connected to the inner side...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com