Wind turbine generator blade bonding corner and preparation method thereof

A technology for wind turbines and bonding angles, which is applied in wind power generation, mechanical equipment, wind engines, etc., to achieve the effects of overcoming wrinkling deformation, high bonding quality, and solving the cracking of blade adhesives

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

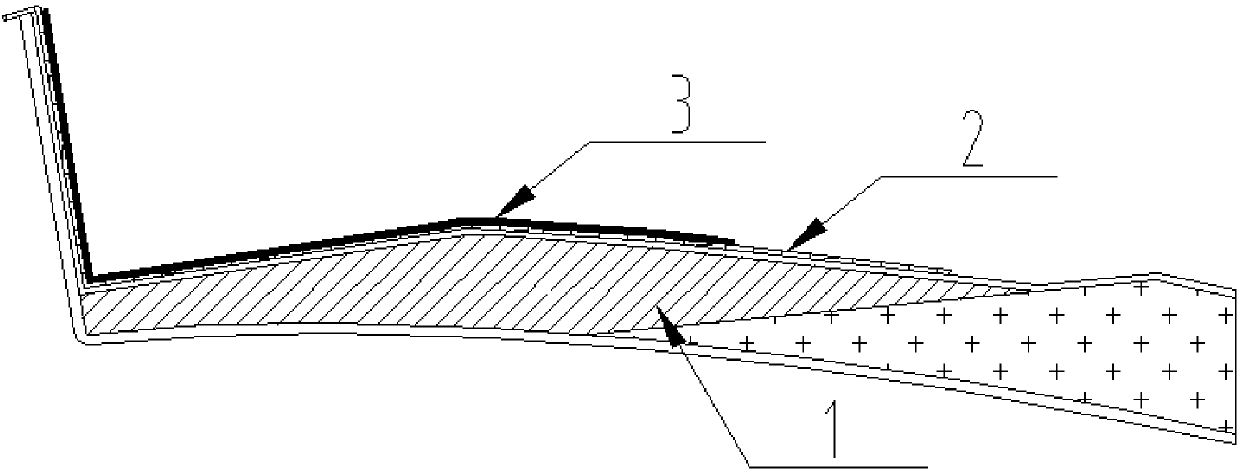

[0038] Refer to attached figure 1 and 2 As shown, this embodiment is used to prepare the SS surface rear edge bonding angle with the PS surface rear edge liner, and its specific preparation method includes the following steps:

[0039] (1) After pre-curing the PS surface shell 1 of the blade PS surface shell of the PS surface trailing edge liner, remove the auxiliary materials within the range of 200mm from the parting line L3m to L15m of the PS surface shell 1 trailing edge of the blade, and clean it up. According to the PS surface shell 1 Lay the vacuum bag film close to the inner wall 2, lay a layer of 150mm wide triaxial cloth within the parting line, then pour the mixed resin evenly on the triaxial cloth, use rollers to soak the resin into the fiber cloth, and drive out Bubble and make the fiber cloth conform to the inner wall of the shell in this area, repeat the above action, and then lay two layers of biaxial cloth and resin, and make the rear edge liner 3 of the PS s...

Embodiment 2

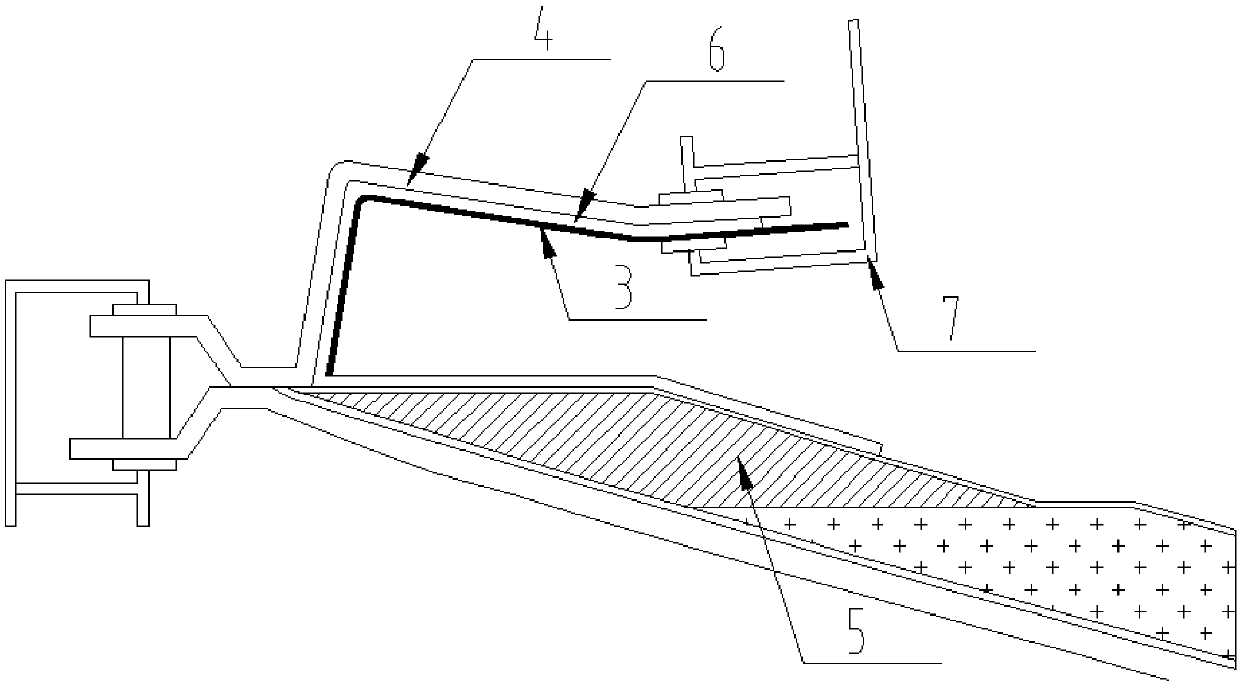

[0047] This embodiment is used to prepare the rear edge bonding angle of the PS surface with the SS surface rear edge liner, and its specific preparation method includes the following steps:

[0048] (1) Production of SS surface trailing edge lining board After the shell layer of the blade SS surface is laid, enter the auxiliary material layout stage, after laying the release cloth, lay 3 layers within the parting line L8m~L14m of the trailing edge of the blade SS surface shell The 180mm wide biaxial cloth is then poured together with the shell of the blade SS surface to obtain the SS surface trailing edge liner.

[0049] (2) After the resin is pre-cured, open the vacuum bag film, use a wallpaper knife to cut off the 30mm release cloth around the rear edge lining board of the SS surface, and open it from one corner, tear the release cloth to remove the rear edge lining board of the SS surface Separate from the SS surface shell, remove the release cloth on the liner, and cut th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com