Truss for raising power transmission line tower

A technology for transmission lines and trusses, applied in towers, coatings, buildings, etc., can solve problems such as easy loosening of the connection position, weak corrosion of the connection position, etc., achieve good fixing effect, high elongation at break, and ensure firmness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

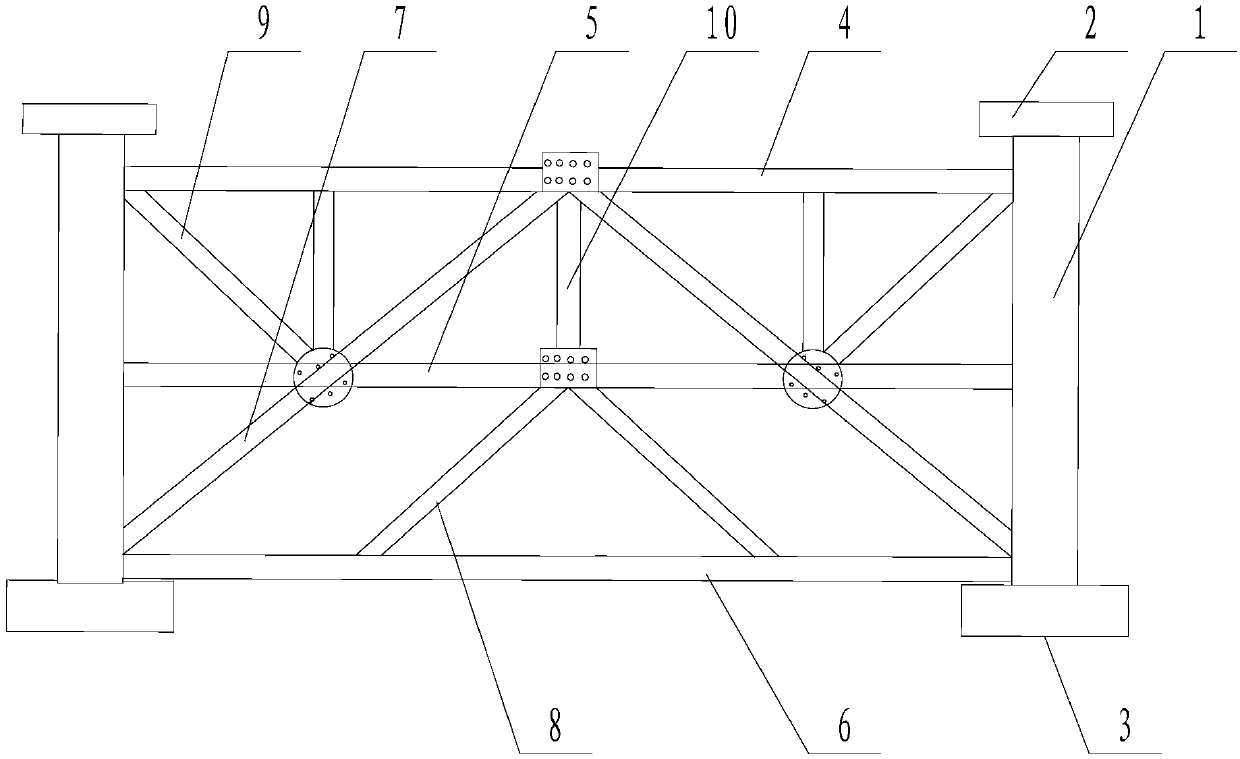

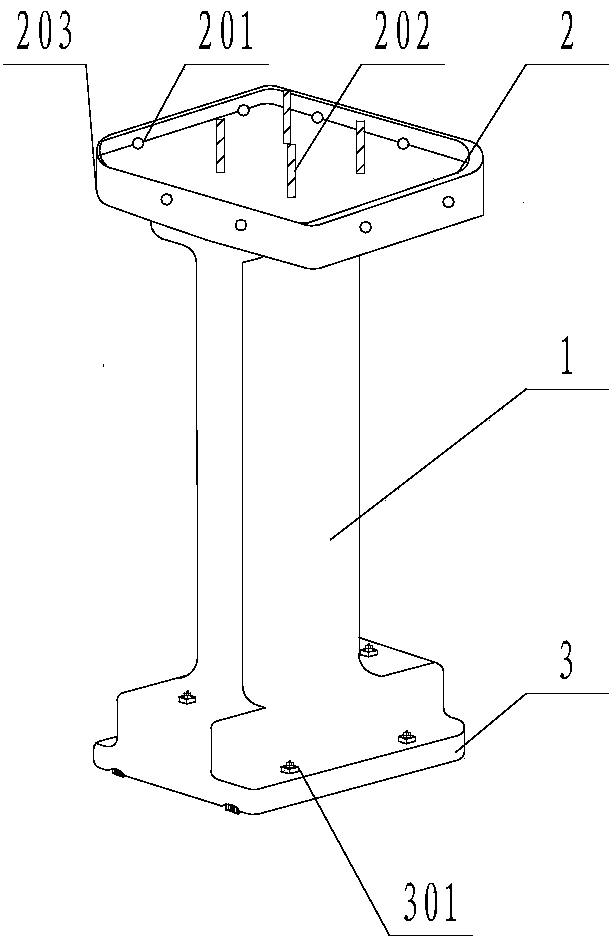

[0024] The truss used for raising the transmission line tower described in this embodiment includes four base columns in an I-shaped structure and a connecting column connecting the four base columns, and the base columns and the connecting columns are coated with antirust paint. The base column includes a column 1, a bottom platform 3 at the bottom of the column 1 for connecting the foundation of the tower, and a top platform 2 at the top of the column 1 for fixing the supporting legs of the tower; the bottom platform 3, the top platform 2 and column 1 are an integral structure, the top platform 2 is surrounded by an outer guard plate 203 higher than the top surface of the top platform 2, the edge of the outer guard plate 203 is provided with an inner buckle edge, and the top surface of the top platform 2 is provided with a The platform 2 is a long stud 202 coated with anti-rust paint on the surface of an integral structure, and a permeable hole 201 is provided at the intersec...

Embodiment 2

[0029] This embodiment is the same as Embodiment 1 except the following features:

[0030] The antirust coating comprises the following raw material components in parts by weight: 10 parts of epoxy resin, 20 parts of N-methylpyrrolidone, 45 parts of polyether polyol (molecular weight is 4000, hydroxyl value 430mgKOH / g), isofor 15 parts of ketone diisocyanate, 7 parts of trimethylolpropane, 2 parts of ethylenediamine, and 3 parts of triethylamine.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com