Fresh lotus seed decorticator

A technology of peeling machine and lotus seeds, applied in the fields of shelling, pod removal, food science, etc., can solve the problems of low quality and low efficiency, and achieve the effect of high work efficiency, convenient operation and saving labor resources.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

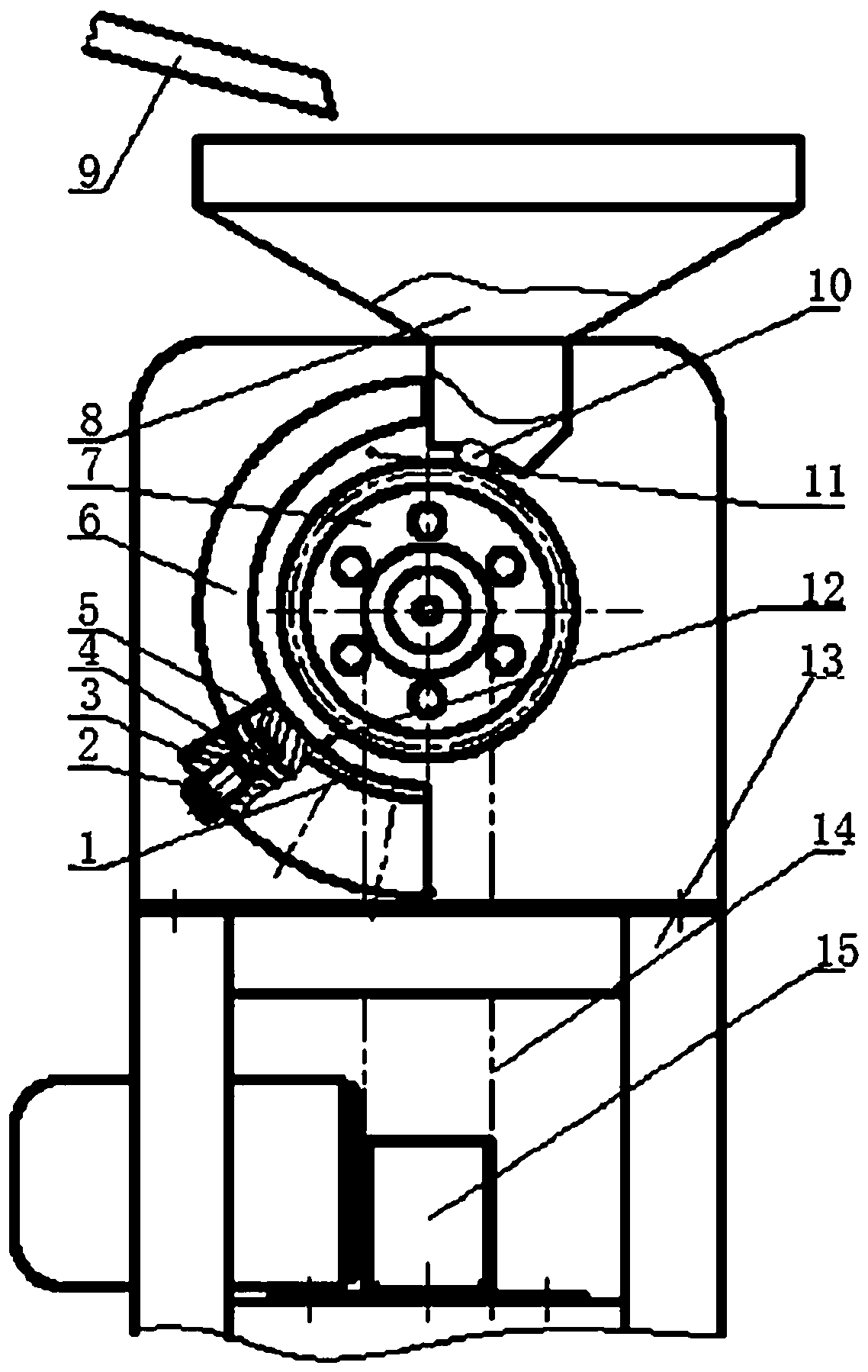

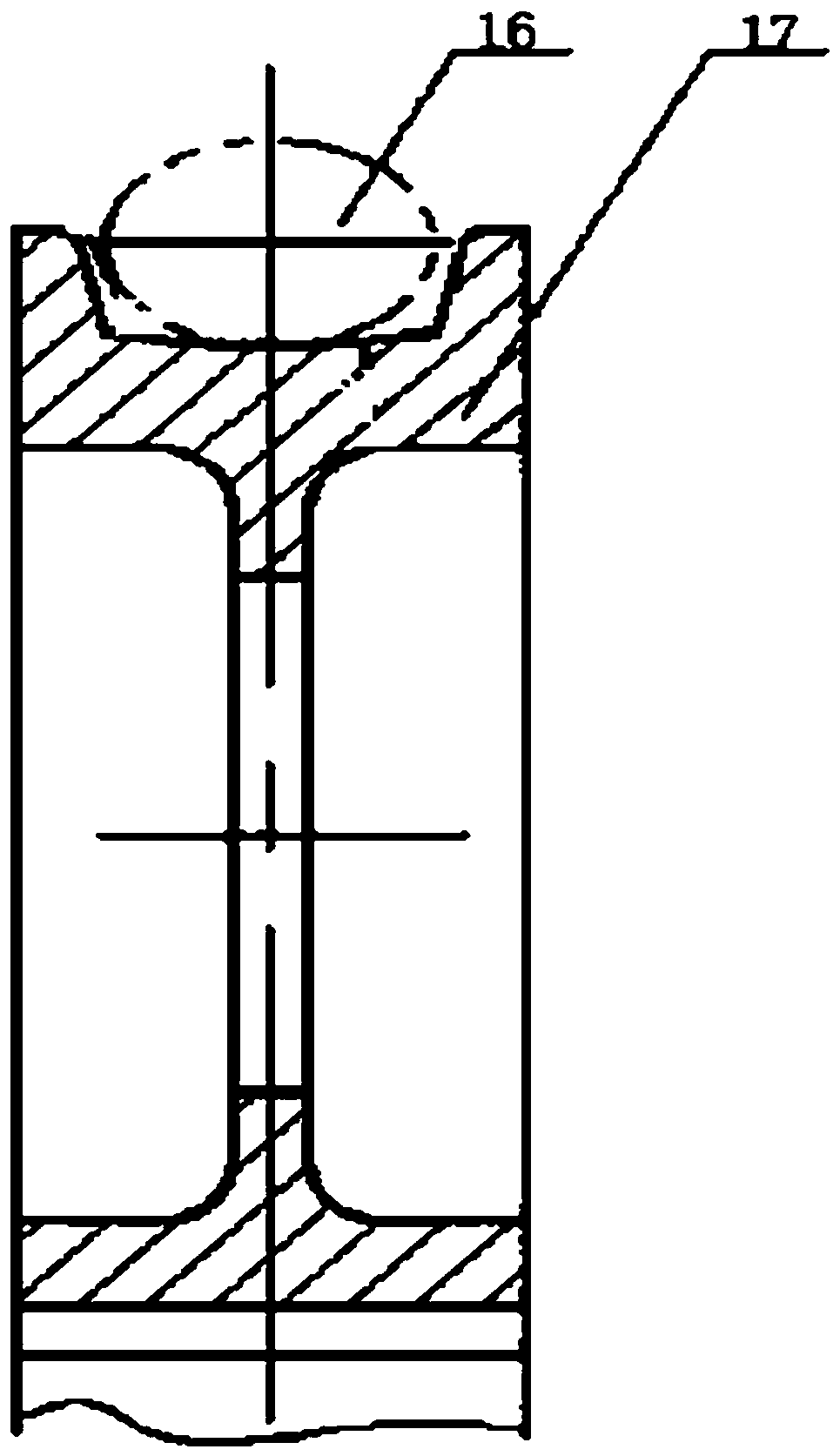

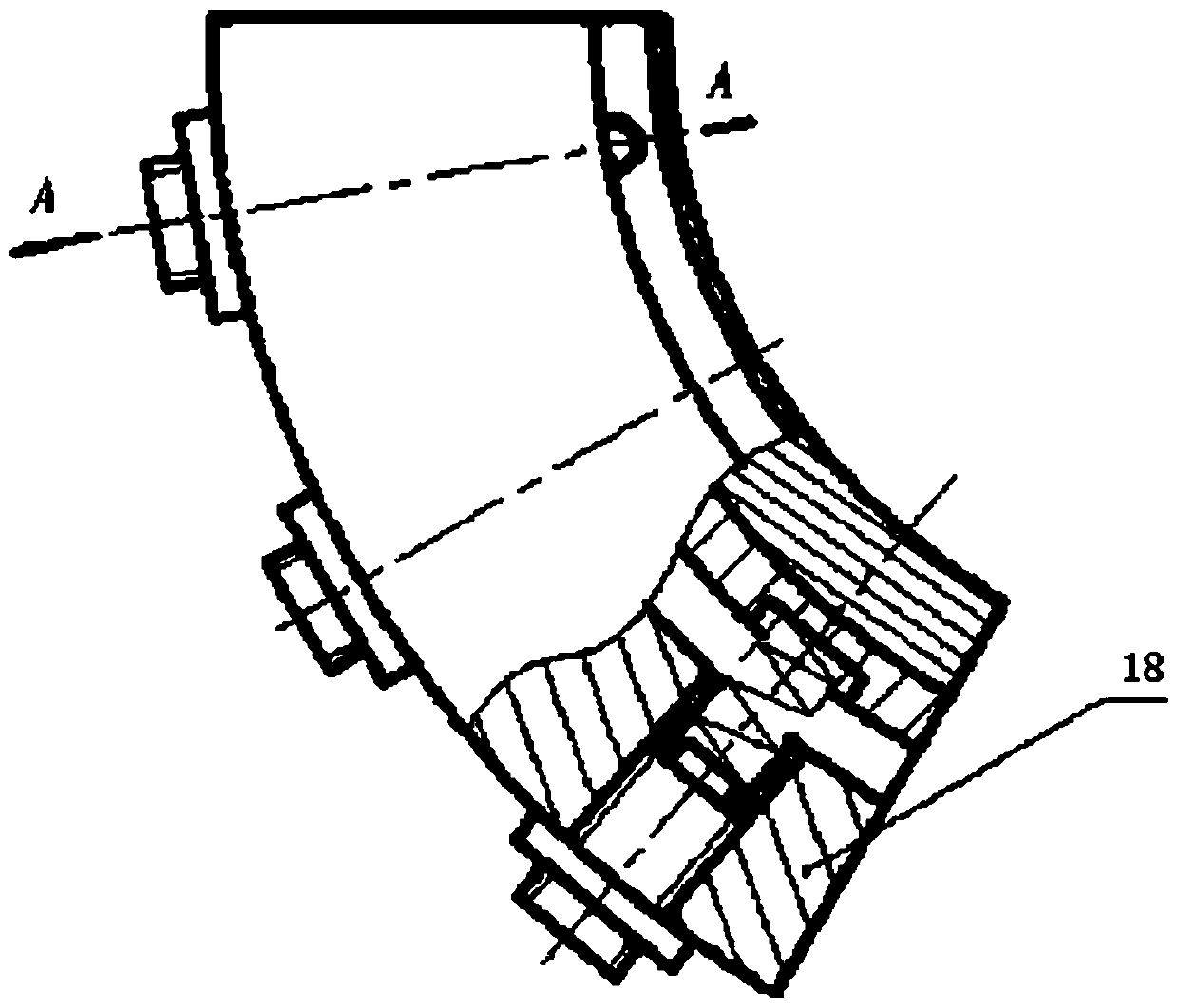

[0017] exist figure 1 Including cutting blades, adjusting screws, guide grooves, adjusting springs, cutting slides, adjusting slides, driving wheels, feeding hoppers, miniature electromagnetic vibrating feeders, lotus seeds, racks and other fixings, adjusting channels, stripping Shell channel, belt, motor, in which the graded fresh lotus seeds (10) enter the hopper (8) from the feeder, and are driven by the drive wheel to enter the adjustment channel of a gradual space formed by the adjustment slideway and the drive wheel , in this channel, the lotus seed is in a rolling state under the pressure of the slideway and the driving wheel and the tangential friction force of the driving wheel. During the rolling process, the lotus seed gradually adjusts the rolling posture until the long axis direction is basically perpendicular to the rolling direction, achieving ideal Then enter the cutting chute (5) composed of the cutting chute and the driving wheel. In this channel, the lotus s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com