Subway seal strip

A technology for sealing strips and subways, applied in sealing devices, engine seals, railway car body parts, etc., can solve the problems of single, non-adjustable extension length, wave gap, etc., and achieve convenient manufacturing, low cost, and simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

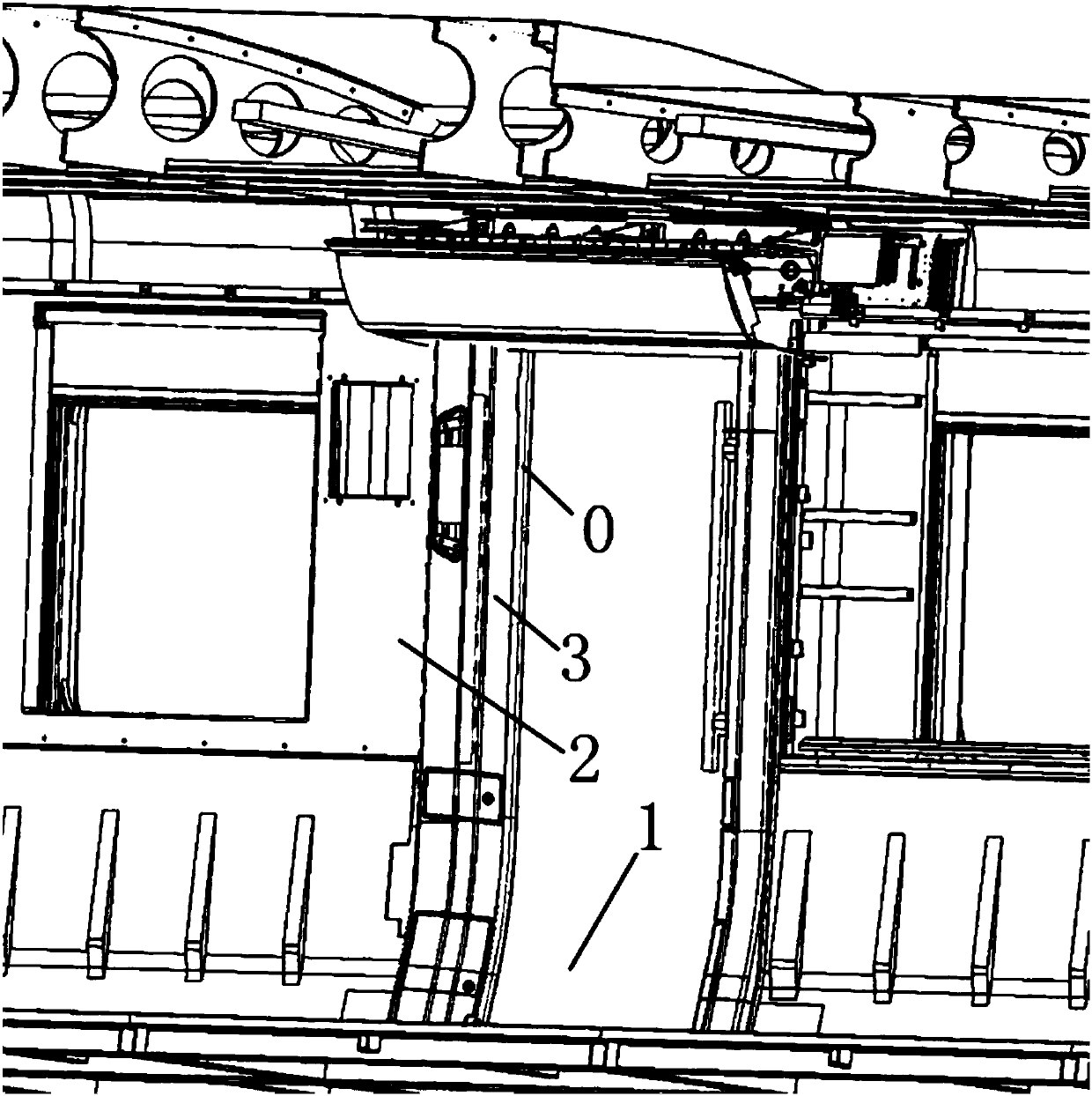

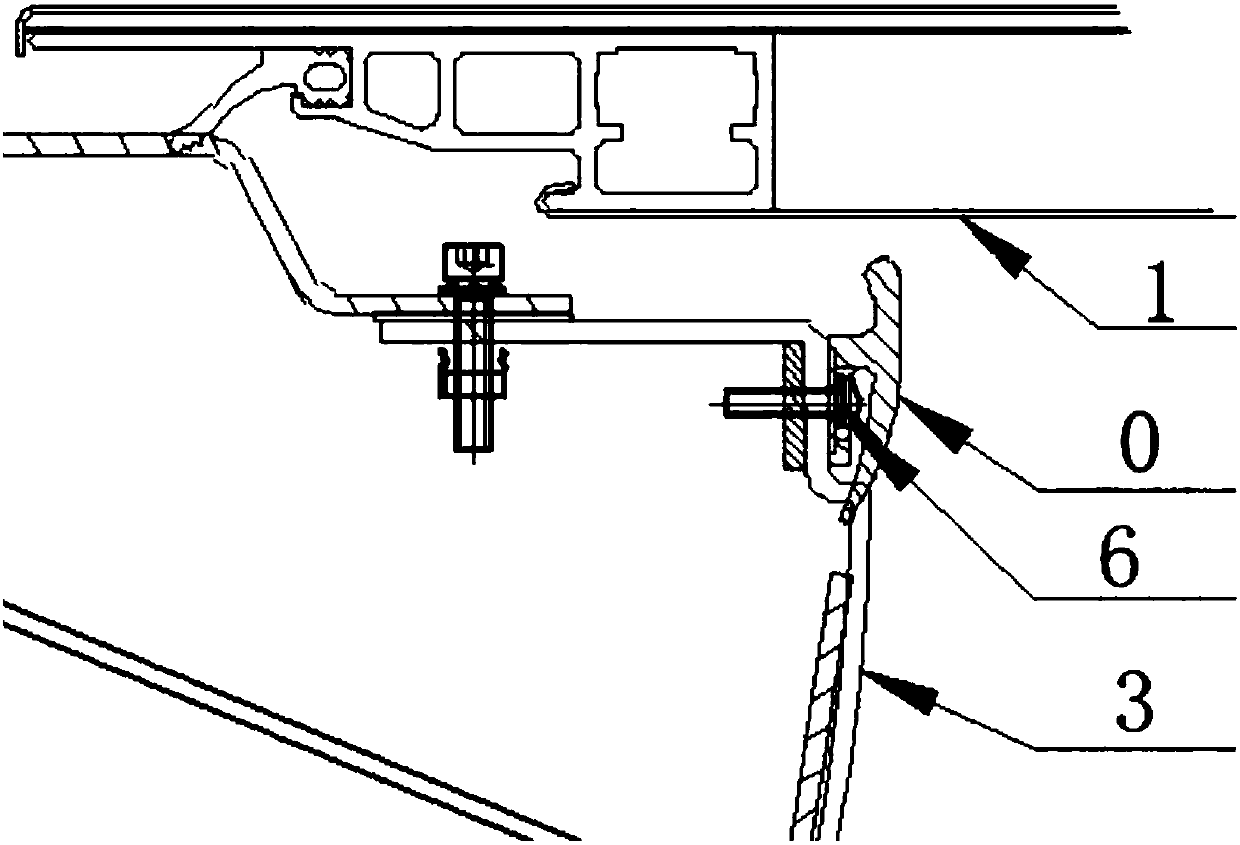

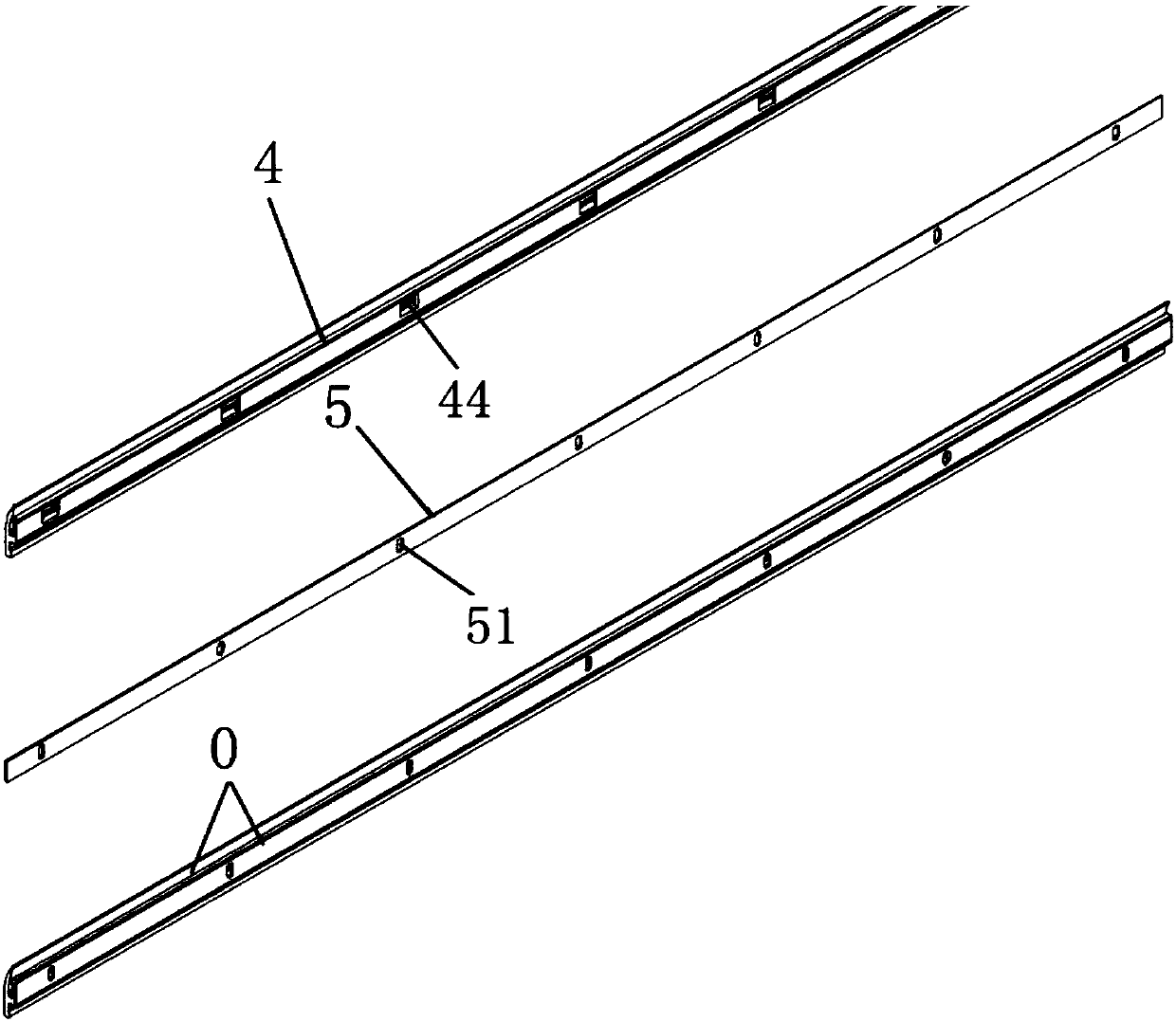

[0029] As shown in the figure: a subway sealing strip 0 is installed on the edge of the door cover 3 between the car door 1 and the side wall 2 through a bolt 6, and is used to seal the car door 1, including a rubber strip 4 and a steel plate 5, the rubber strip 4 is fixed on the steel plate 5, and the steel plate 5 is fixed on the door vertical cover 3 by bolts 6, and the subway sealing strip 0 is the same height as the door vertical cover 3.

[0030] The rubber strip 4 includes a fixing part 41, a connecting part 42 and a sealing part 43. The fixing part 41 is in the shape of a 匚, and the top side is connected with the sealing part 43 through the connecting part 42. The 43-shaped top is circular, and it is pushed on the car door 1, and the upper middle position is connected with the connecting part 42, and the bottom is tightly buckled on the door stand cover 3.

[0031] The oblong mounting holes 51 are uniformly arranged on the steel plate 5 , and the oblong mounting holes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com