Homogeneous vibration device used for bottled powder medicine production

A technology of pharmaceutical production and oscillation device, which is applied to the types of packaged items, packaging, and vibrating conveyors. It can solve the problems of low production efficiency, powder column not collapsing, and large oscillation noise, and achieve good practical effects and continuous production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

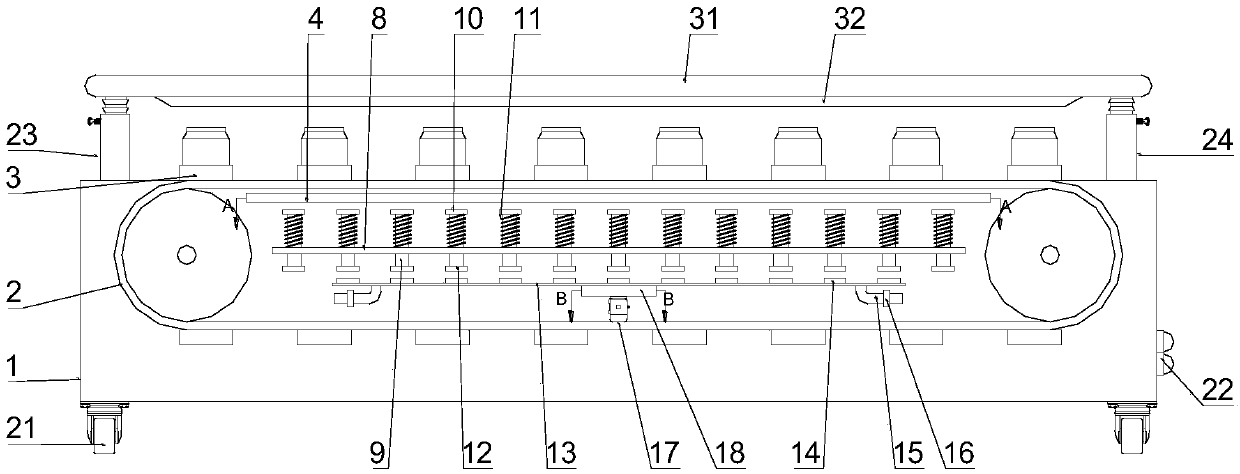

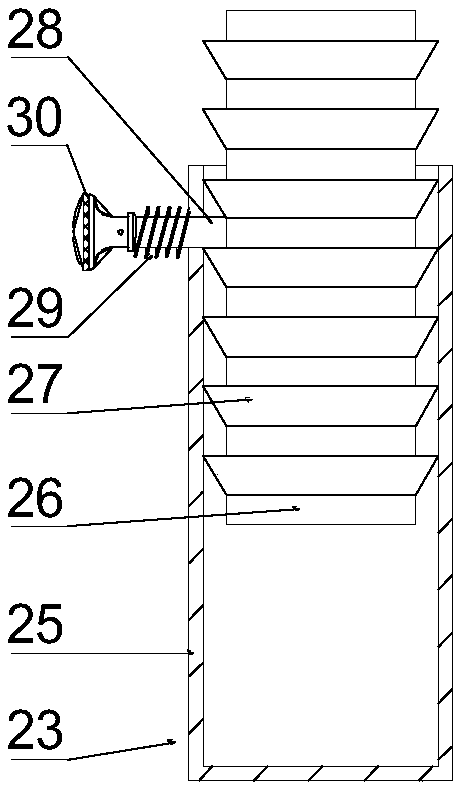

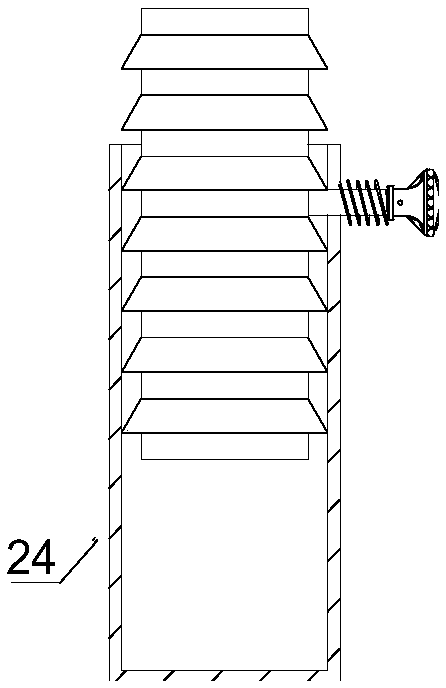

[0020] see Figure 1-5 , a homogeneous oscillation device for bottled powder medicine production, comprising a frame 1, a conveyor belt 2, a fixed plate 4, a vibrating plate 6, an elastic rope 7, a connecting plate 8, a movable column 9, a coil spring 11, an impact block 10, a guide Device, intermittent driving device, first height adjustment device, second height adjustment device and limit plate 31, the conveyor belt 2 is installed on the frame 1, and the inner middle upper side of the conveyor belt 2 is provided with a fixed connection on the frame 1 The fixed plate 4 is evenly opened with a number of mounting holes 5 on the fixed plate 4, and the vibrating plate 6 is arranged in the mounting hole 5. The vibrating plate 6 is fixedly connected with the fixed plate 4 through a number of elastic ropes 7. The fixed plate 4 The lower part of the fra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com