Method for optimizing RH dynamic decarburization based on flue gas analysis

A technology of flue gas analysis and optimization method, which is applied in the field of iron and steel metallurgy RH refining, can solve the problems of no operability and no implementation method, and achieve the effect of improving the analysis level, great promotion value, and good application effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

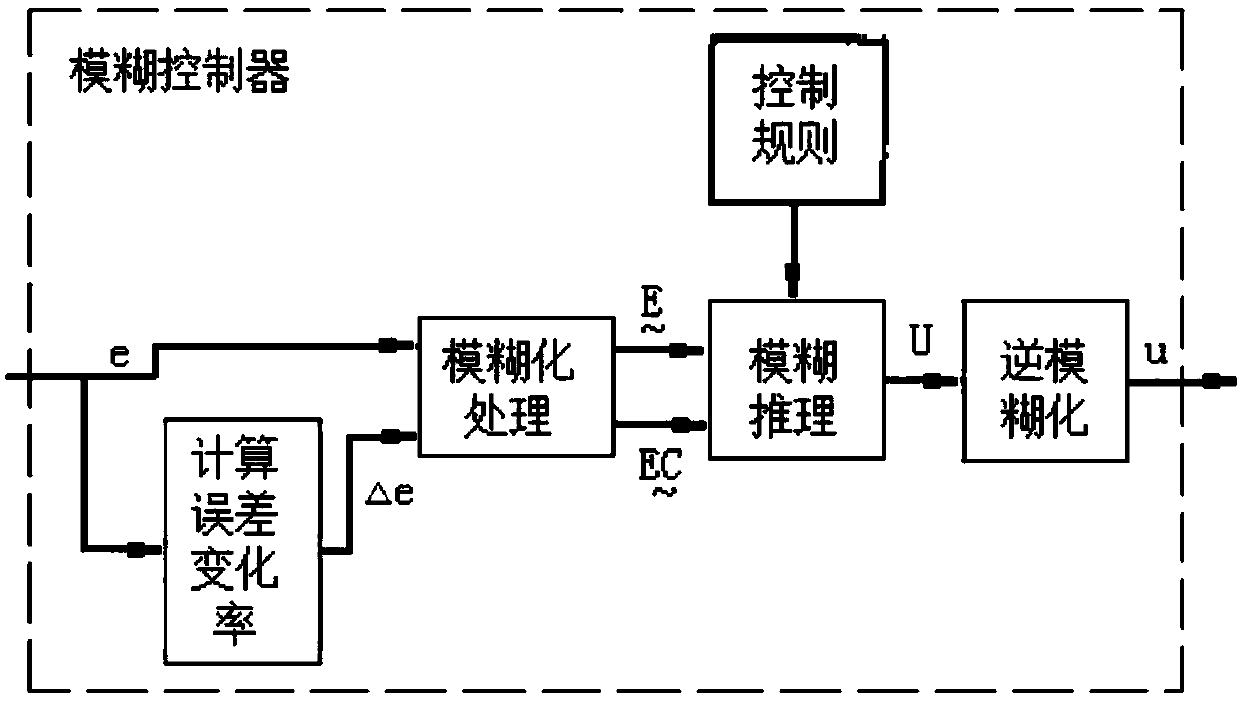

Image

Examples

Embodiment Construction

[0044] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

[0045] A RH dynamic decarburization optimization method based on flue gas analysis, comprising the following steps:

[0046] 1) The data acquisition and processing system collects, analyzes and processes exhaust gas components and exhaust gas flow data in the RH production process in real time, and transmits them to the RH control system;

[0047] 2) In the RH control system, the RH dynamic decarbonization model is established according to the RH production system data and actual production needs; the specific process is as follows:

[0048] The carbon contents of the molten steel in the ladle and the molten steel in the vacuum chamber are respectively CL and Cv. For the molten steel in the ladle, according to the principle of mass conservation of carbon content in the molten steel, the decarburization mathematical equation can be expressed by for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com