Connecting structure of steel tank ditch and glass daylighting roof and connecting method thereof

A technology for connecting structures and lighting roofs, which is applied in building structures, roofs, buildings, etc., can solve the problems of increasing the difficulty of engineering construction, increasing the cost, and being non-adjustable, so as to improve the scope of application and versatility, improve safety, and reduce The effect of cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

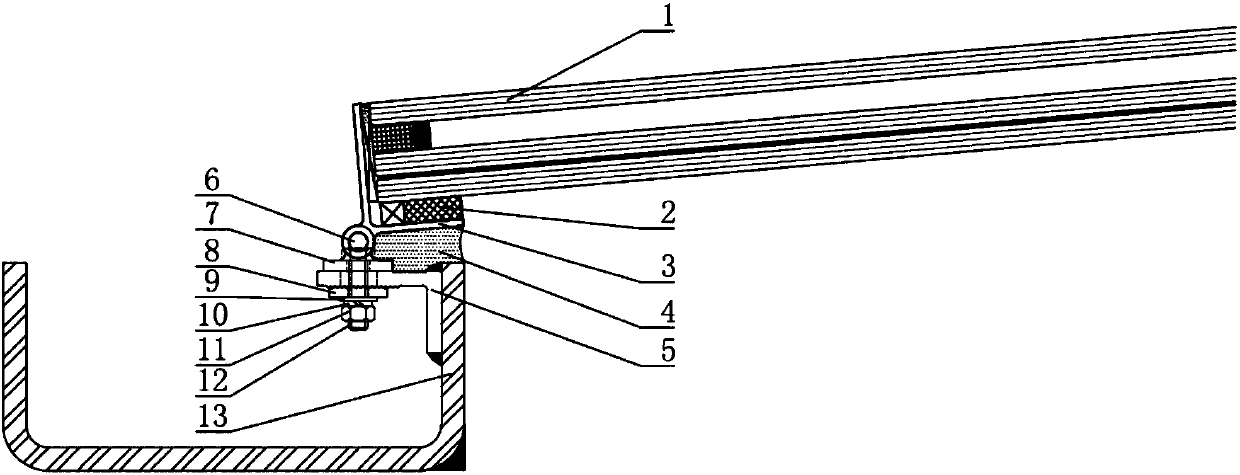

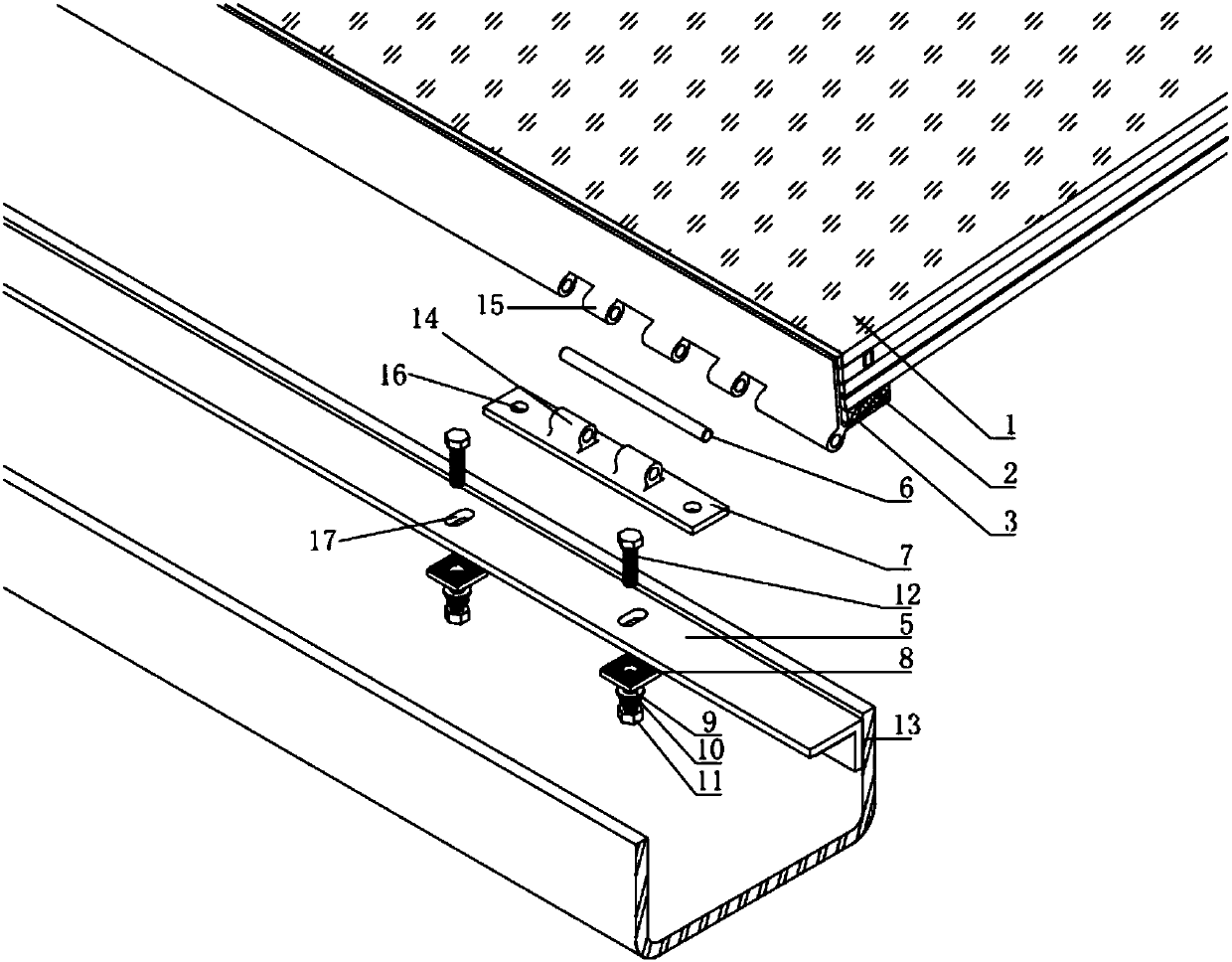

[0030] Such as Figure 1 to Figure 2 As shown, the connection structure between the steel channel gutter and the glass daylighting roof shown in this embodiment includes the L-shaped aluminum alloy sub-frame 3 bonded together with the glass daylighting roof, the base 7 and the steel channel gutter 13 The angle steel 5, the base 7 and the L-shaped aluminum alloy sub-frame 3 are connected in a rotatable manner, the angle steel 5 is fixedly connected with the base 7, so that the steel channel water ditch 13 is arranged under the glass lighting roof, and the L-shaped The aluminum alloy sub-frame 3 can rotate relative to the steel channel water ditch 13, and then the inclination angle of the glass daylighting roof can be adjusted under the condition that the steel channel water channel 13 is horizontal.

Embodiment 2

[0032] Such as Figure 1 to Figure 2 As shown, the connection structure between the steel channel gutter and the glass daylighting roof in this embodiment includes the L-shaped aluminum alloy sub-frame 3 bonded together with the glass daylighting roof, the base 7 and the inner side of the steel channel gutter 13 welded The angle steel 5 at the upper end, the base 7 are movably connected with the L-shaped aluminum alloy sub-frame 3, and the angle steel 5 and the base 7 are fixedly connected together by a bolt assembly, so that the steel channel water ditch 13 is arranged under the glass daylighting roof. Through this connection structure, the The L-shaped aluminum alloy sub-frame 3 can rotate relative to the steel channel gutter 13, and then the inclination angle of the glass lighting roof can be adjusted under the condition that the steel channel gutter 13 is level.

[0033] Among them, the glass used in the glass lighting roof is tempered hollow laminated glass 1, and the end...

Embodiment 3

[0039] A connection method using the connection structure of embodiment 2, comprising the following steps:

[0040] S1. Bond the L-shaped aluminum alloy sub-frame to the end of the tempered hollow laminated glass in the glass lighting roof;

[0041] S2. Fix the T-shaped aluminum alloy base to the upper end of the angle steel on the steel channel gutter through the bolt assembly;

[0042] S3. After the glass daylighting roof is engaged with the first penetration part on the T-shaped aluminum alloy base through the second penetration part at the outer lower end of the L-shaped aluminum alloy sub-frame 3, insert the stainless steel pin shaft into the first penetration part and the second penetration part In the hole on the top, so that the two can be rotatably connected together;

[0043] S4. When adjusting the angle between the glass lighting roof and the steel channel gutter to the design requirements, fill the silicone weather-resistant sealant between the stainless steel ang...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap