Hydraulic system

A technology for hydraulic systems and hydraulic actuators, applied in the directions of fluid pressure actuating system components, fluid pressure actuating devices, servo motors, etc., can solve problems such as troublesome, inoperable by non-transferred personnel, and achieve the change of working flow and improving operation. Efficiency, control stable and reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The specific implementation will be described below in conjunction with the accompanying drawings.

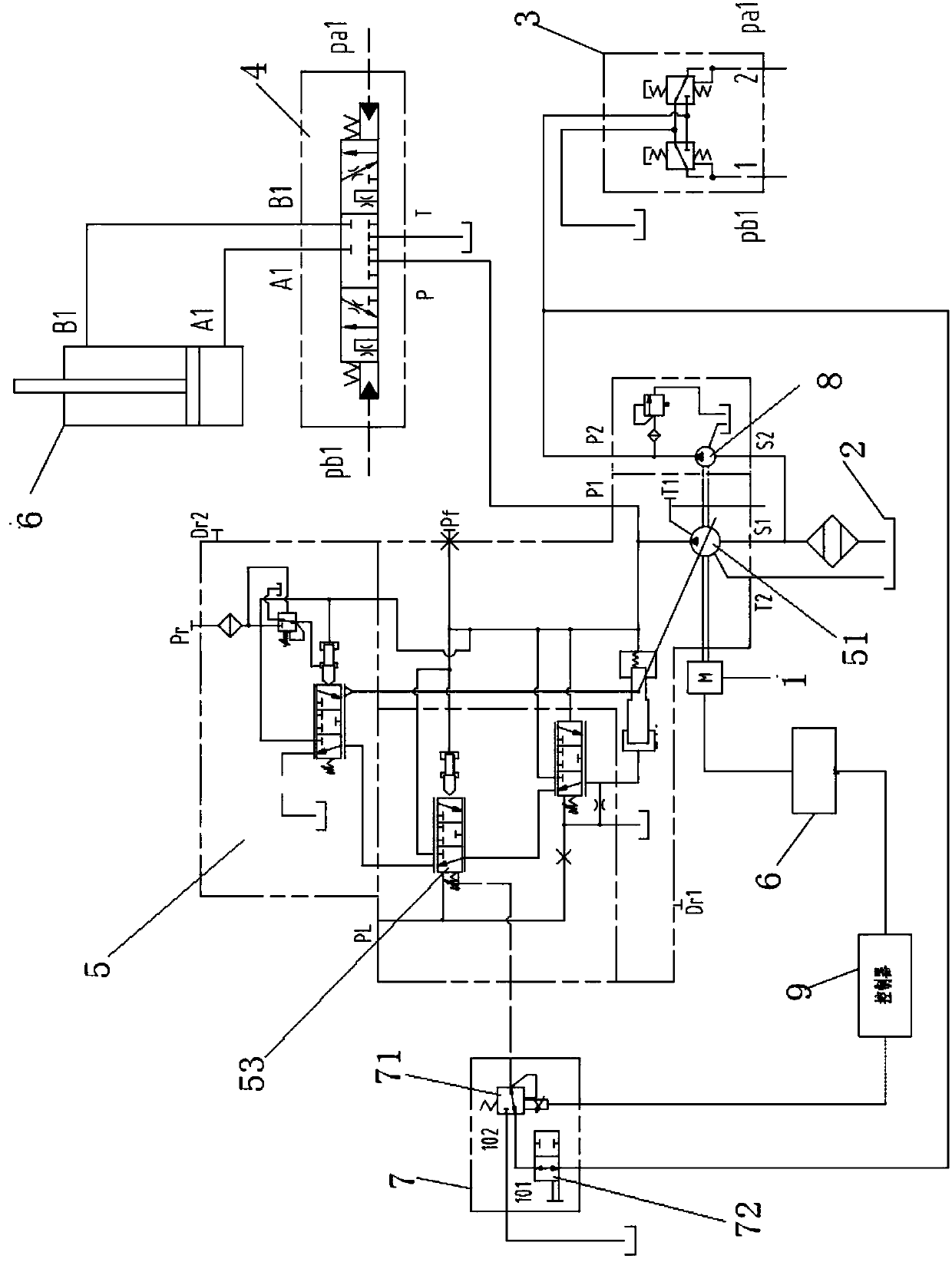

[0016] The hydraulic system in this embodiment is as figure 1 As shown, it includes attachment hydraulic actuators, control valve group 7, multi-way valve 4, variable displacement pump 5, pilot valve 3, pilot pump 8, and controller 9.

[0017] The attachment hydraulic actuator may be the attachment cylinder 6, or a hydraulic motor or other devices that use hydraulic energy as the driving energy.

[0018] There are multiple control valves in the multi-way valve 4, which are used to control different hydraulic actuators, including hydraulically controlled attachment control valves for controlling attachments.

[0019] The variable pump 5 includes a load sensing valve 53 and a plunger pump 51. The load feedback oil circuit PL interface of the variable pump 5 is connected to the left end of the load sensing valve 53, and the pump port of the plunger pump 51 is connected to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com