Polarity reversal driving method of liquid crystal display device and source driver

A liquid crystal display and source driver technology, applied to static indicators, instruments, etc., can solve the problems of image quality reduction, interference noise at the top and bottom of the pattern, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

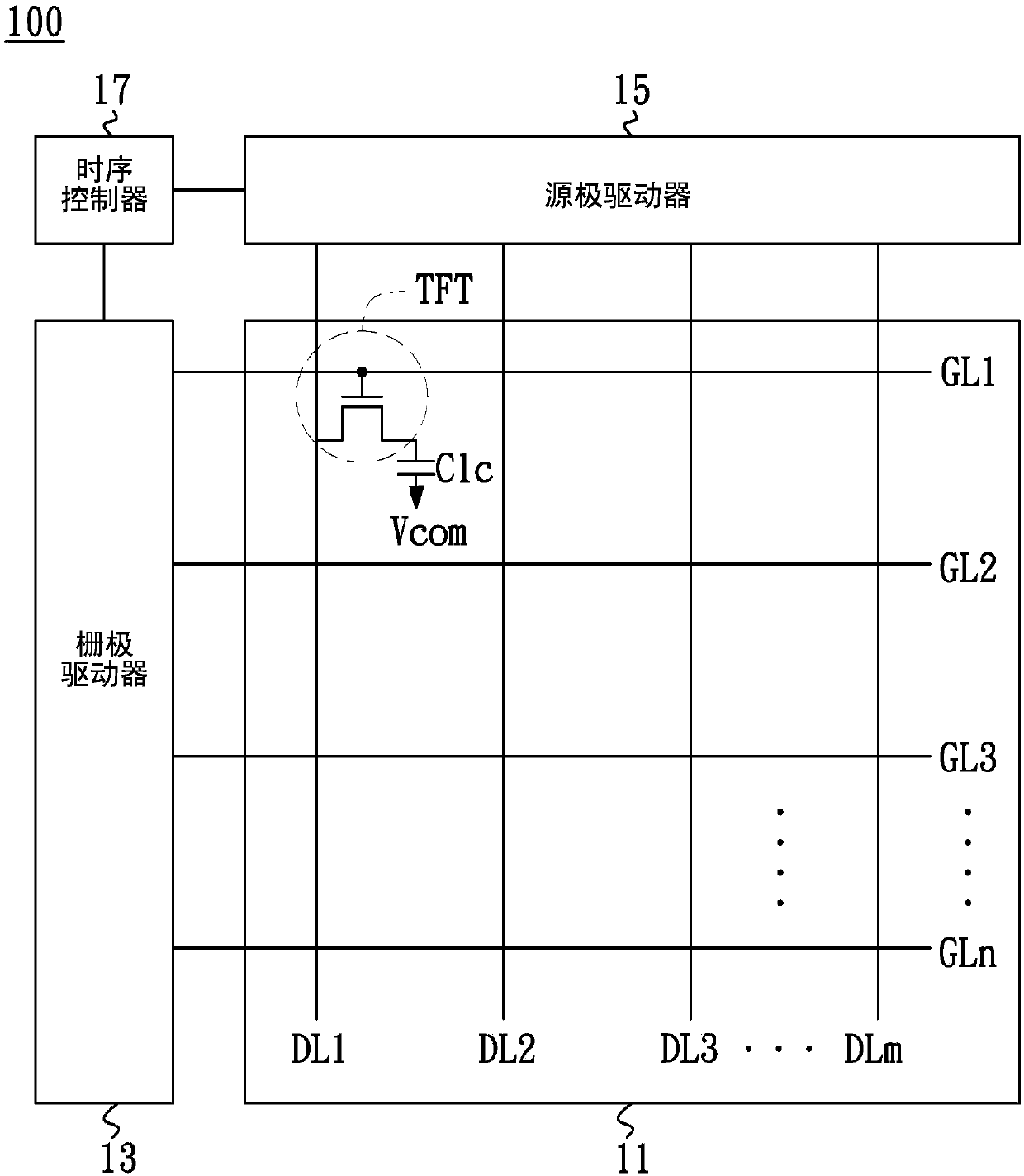

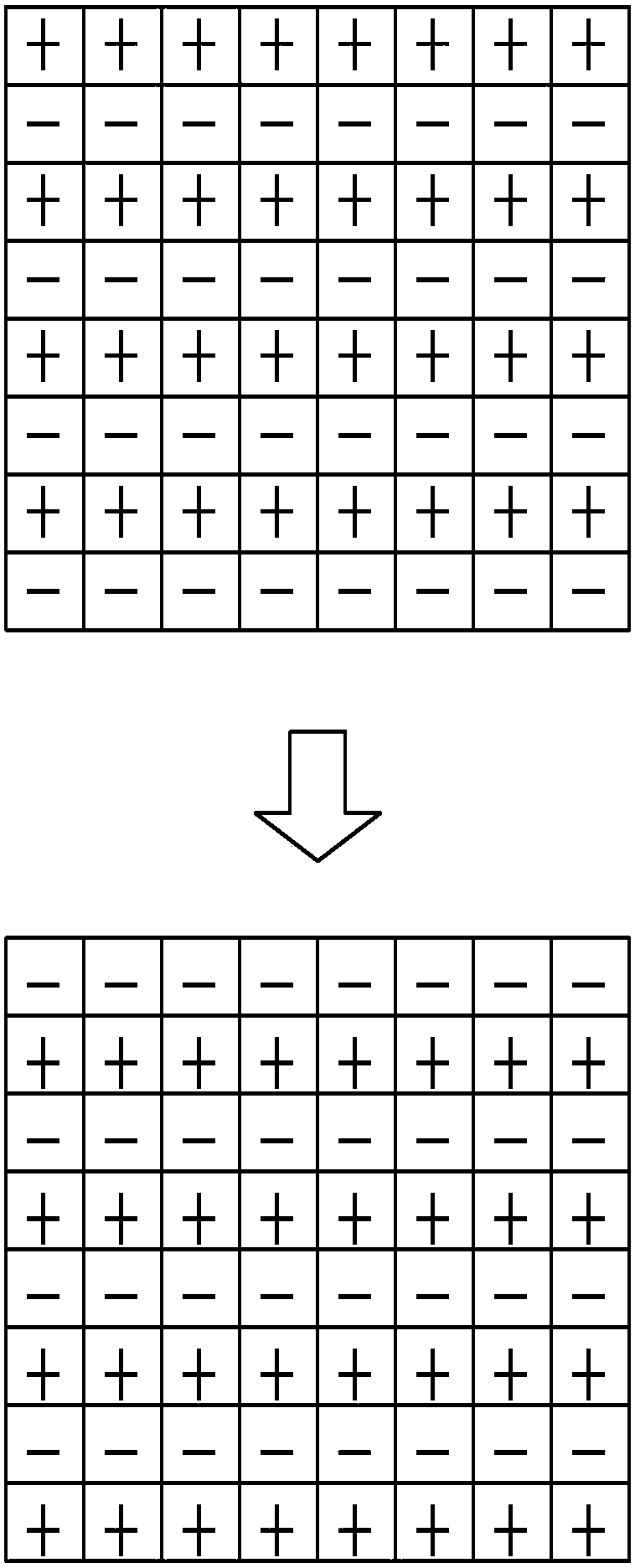

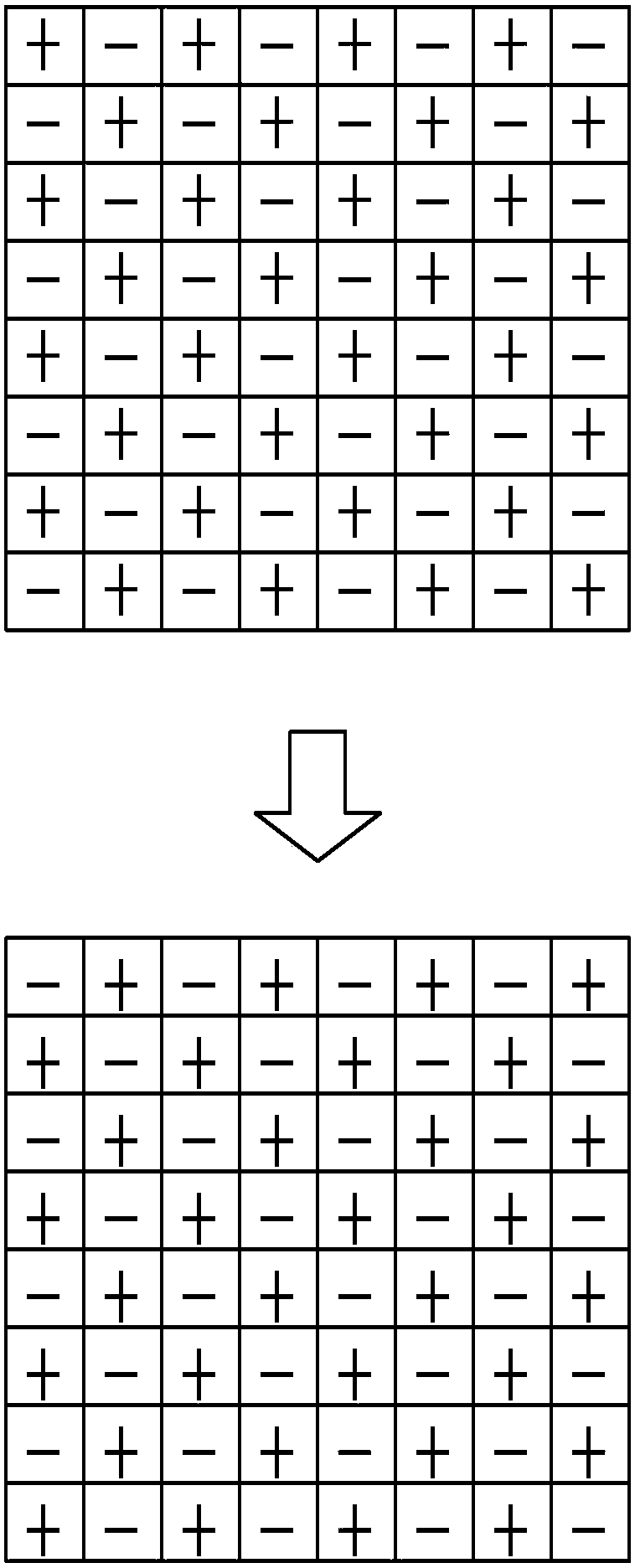

[0043] Figure 5 The flow chart showing the polarity inversion (polarity inversion) driving method of the liquid crystal display 100 according to the embodiment of the present invention, the system architecture of the liquid crystal display 100 follows figure 1 system block diagram. Figure 6 to Figure 9 A simplified schematic diagram showing a polarity inversion driving method of the liquid crystal display 100 according to an embodiment of the present invention illustrates the pixel polarities of the first, third, fifth and seventh frames respectively. The pixel polarities of the second, fourth, sixth and eighth frames are omitted and not shown, wherein the pixel polarity of the second frame is opposite to that of the first frame ( Figure 6 ), the pixel polarity of the fourth frame is opposite to that of the third frame ( Figure 7 ), the pixel polarity of the sixth frame is opposite to that of the fifth frame ( Figure 8 ), the pixel polarity of the eighth frame is oppos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com