Dipole gas discharge tube structure

A technology of gas discharge tube and discharge tube, which is applied in the direction of circuits, electrical components, spark gaps, etc., can solve the problems of internal structure deformation, melting, and electrode thermal deformation of the tube body, so as to ensure consistency, improve stability, and extend service life The effect of longevity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

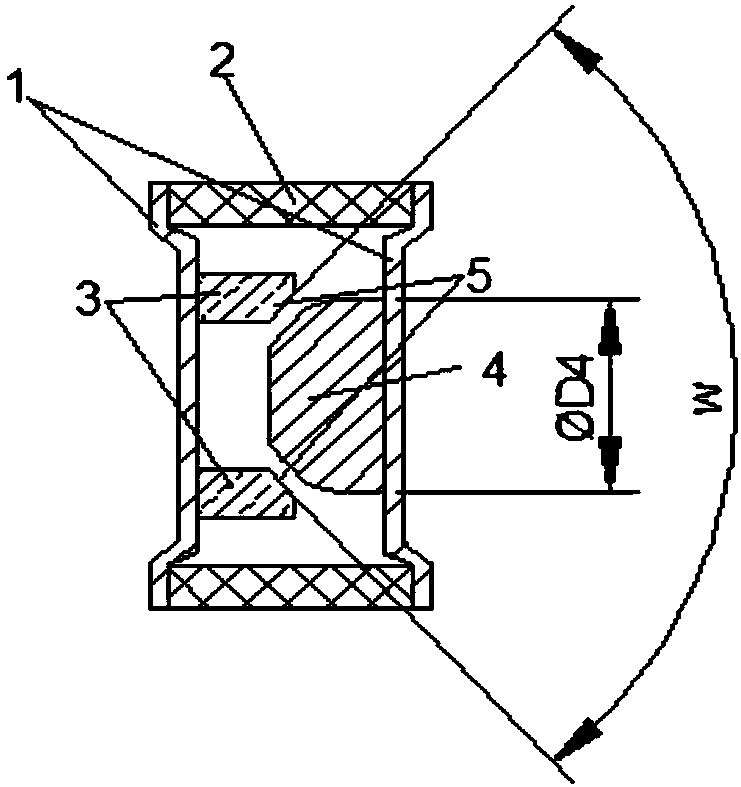

[0020] Preferred embodiments of the present invention will be described in more detail below with reference to the accompanying drawings. Although preferred embodiments of the invention are shown in the drawings, it should be understood that the invention may be embodied in various forms and should not be limited to the embodiments set forth herein.

[0021] The new gas discharge diode consists of the following parts:

[0022] 1. Two flat electrodes;

[0023] 2. One ceramic tube;

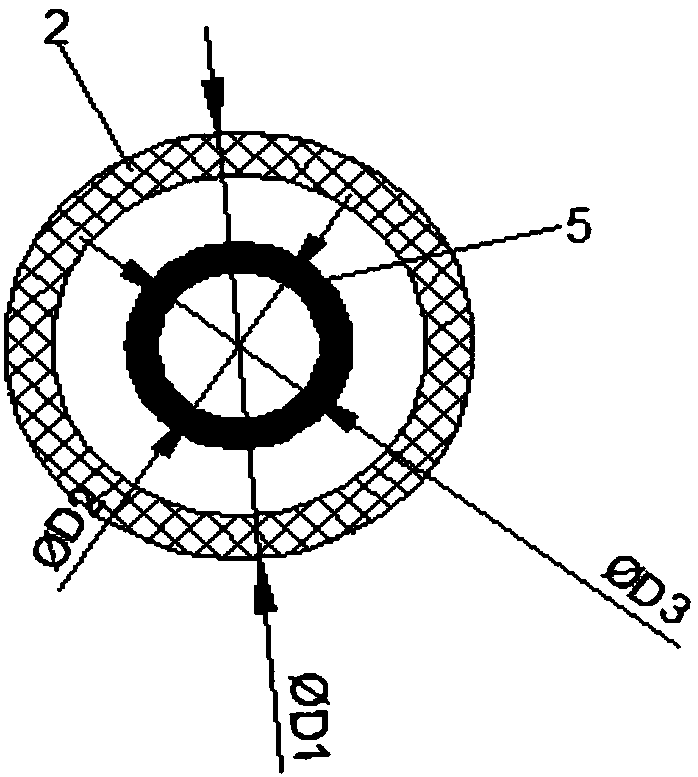

[0024] 3. One ring electrode, the inner diameter of the ring electrode discharge surface is ΦD2, and the outer diameter of the ring electrode discharge surface is ΦD3;

[0025] 4. One needle electrode, the diameter of the needle electrode is ΦD4;

[0026] The ring electrode and the needle electrode are designed with a curved surface, and the area of the discharge surface is S: S=wπ(D3 / 2)2 / 360-wπ(D2 / 2)2 / 360; where D2 is the inner diameter of the discharge surface of the ring electrode 3; D3 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com