A chitosan-based gradient biomimetic composite scaffold material and its construction method

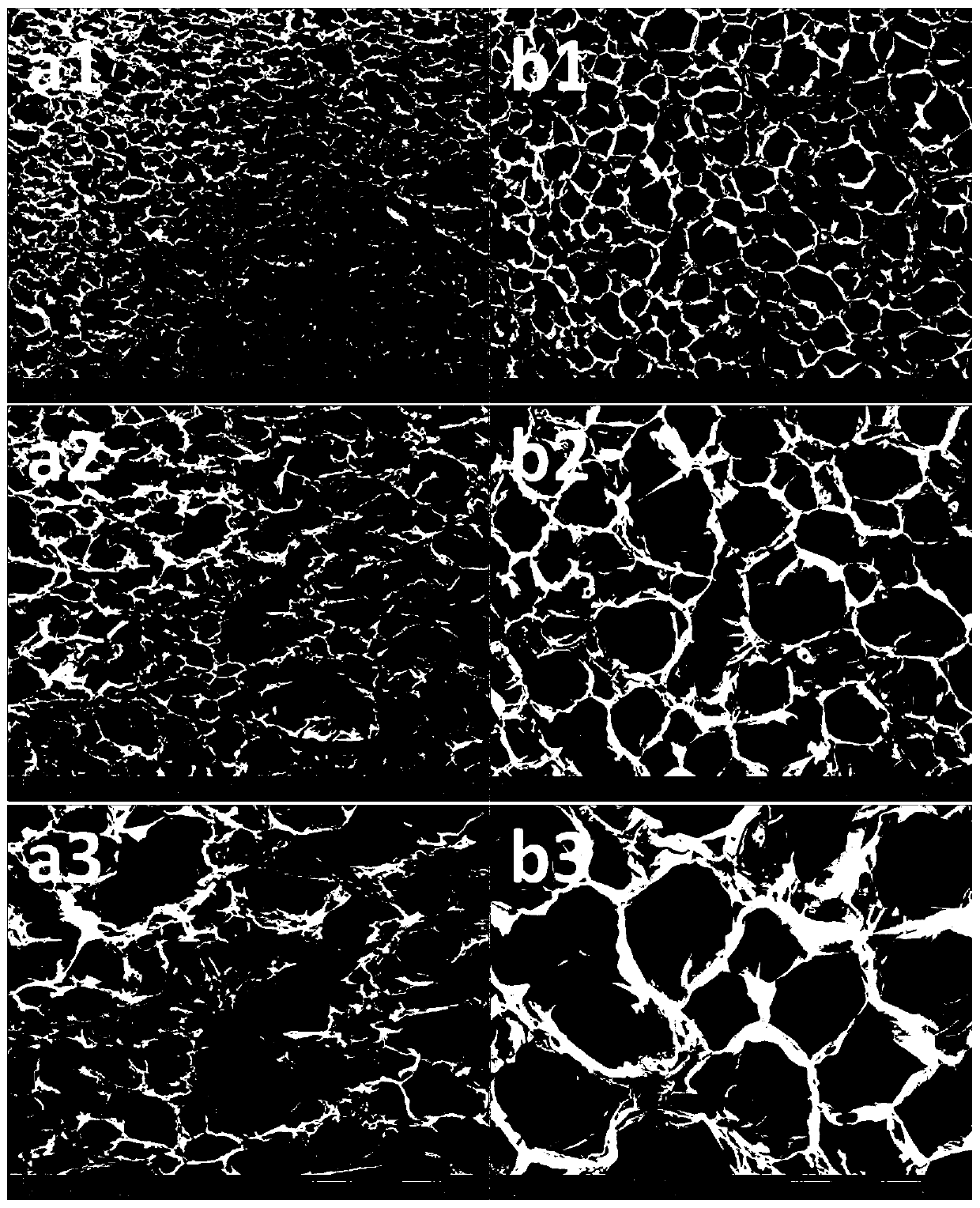

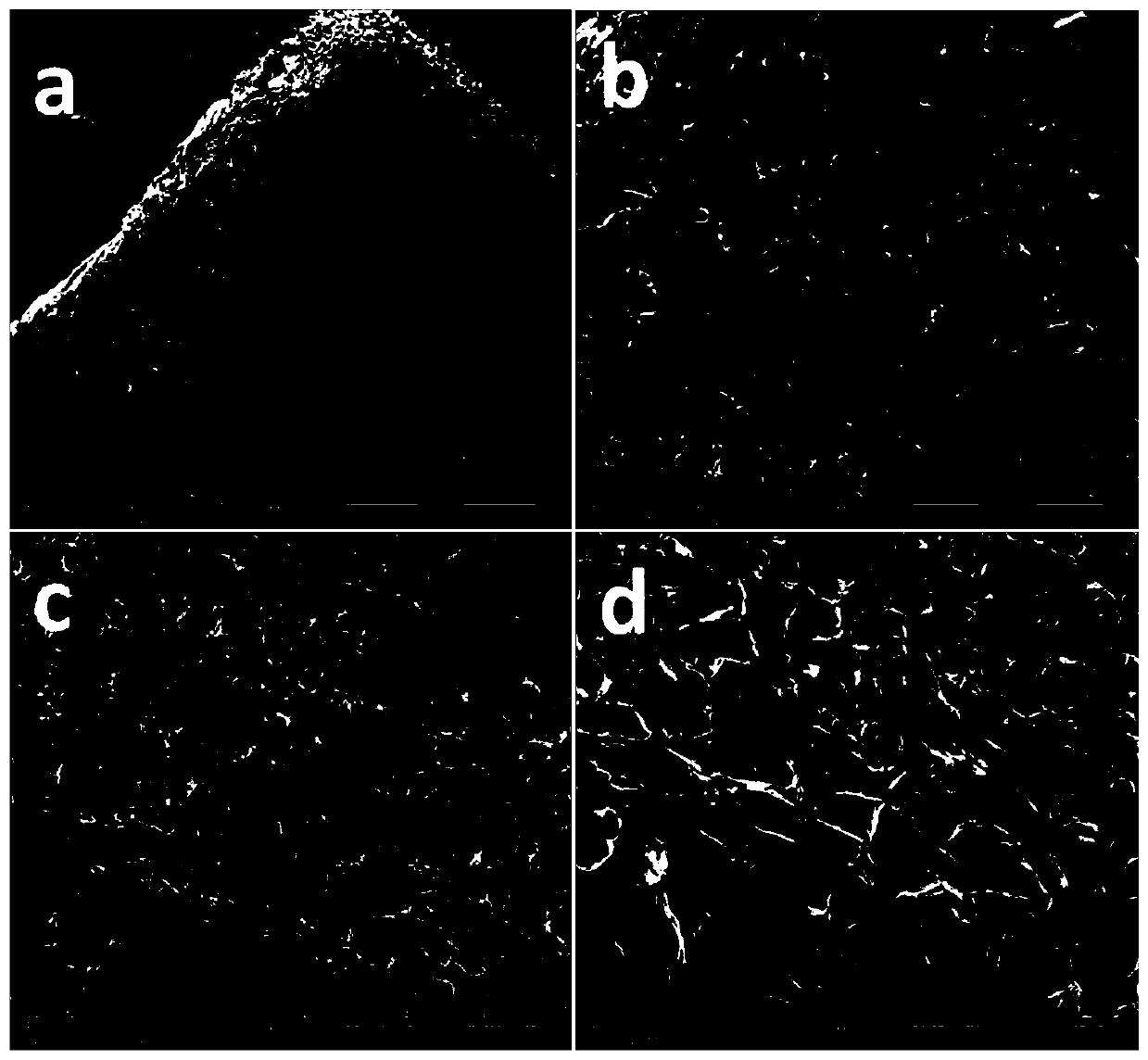

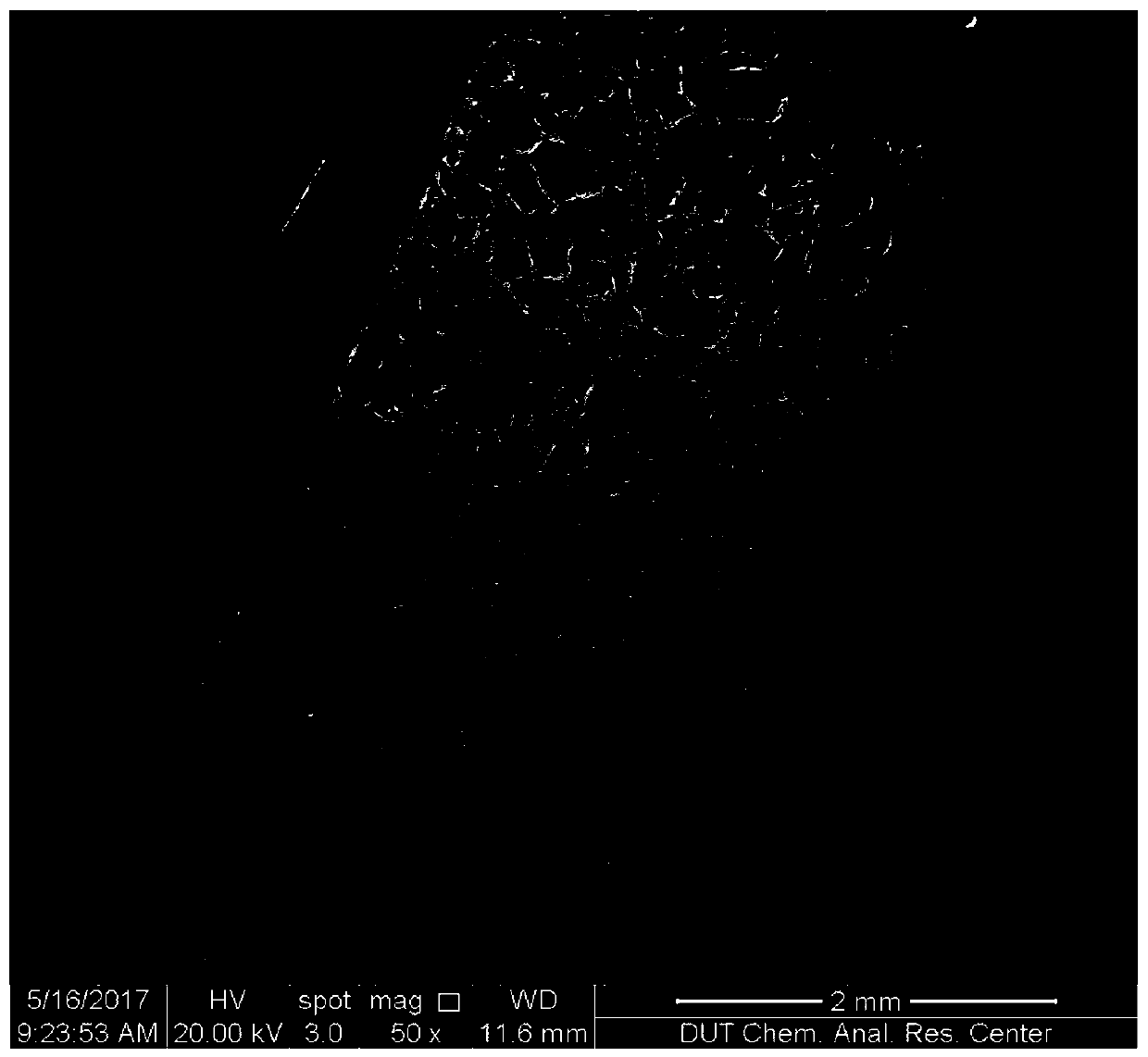

A composite scaffold and construction method technology, applied in medical science, prosthesis, etc., to achieve stable structure, uniform pore size, and good connection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Example 1 Preparation of Cs / GP / Gel (mass ratio 1:15.2:1.8) physical blending composite scaffold material (as a comparative example)

[0039] Weigh 2.2 g of chitosan powder, add it into 100 mL of 0.1 mol / L acetic acid solution, and stir magnetically for 2 h at 40° C. to make it evenly mixed. Centrifuge at 1000rpm for 0.5h to degas the chitosan solution and remove slag. Weigh 20.0 g of sodium β-glycerophosphate powder, add it into 20 mL of deionized water, and stir magnetically at room temperature for 30 min to dissolve it evenly. Weigh 6.0 g of gelatin particles, add to 100 mL of deionized water, and stir magnetically for 30 min at 40°C to make them evenly mixed. At room temperature, the prepared chitosan solution was stirred rapidly on a magnetic stirrer, and the β-sodium glycerophosphate solution was slowly added dropwise during the stirring process, and the solution was fully stirred for 30 minutes to prepare a Cs / GP solution. Observe that there is no obvious floccu...

Embodiment 2

[0040] Example 2 Preparation of Cs / GP / Gel (mass ratio 1:6.7:3.1) physical blending composite scaffold material (as a comparative example)

[0041] Weigh 2.5 g of chitosan powder, add it into 100 mL of 0.1 mol / L acetic acid solution, and stir magnetically for 3 h at 50° C. to make it evenly mixed. Centrifuge at 1000rpm for 0.5h to degas the chitosan solution and remove slag. Weigh 24.0 g of sodium β-glycerophosphate powder, add it to 16 mL of deionized water, and stir magnetically at room temperature for 40 min to dissolve it evenly. Weigh 7.0 g of gelatin particles, add to 100 mL of deionized water, and stir magnetically for 40 min at 50°C to make them evenly mixed. At room temperature, the prepared chitosan solution was stirred rapidly on a magnetic stirrer, and the β-sodium glycerophosphate solution was slowly added dropwise during the stirring process, and the solution was fully stirred for 30 minutes to prepare a Cs / GP solution. Observe that there is no obvious flocculen...

Embodiment 3

[0042] Example 3 Preparation of Cs / GP / Gel (mass ratio 1:8.4:1.5) physical blending composite scaffold material (as a comparative example)

[0043]Weigh 3.0 g of chitosan powder, add it into 100 mL of 0.1 mol / L acetic acid solution, and stir magnetically for 4 h at 50° C. to make it evenly mixed. Centrifuge at 1000rpm for 1h to degas and deslag the chitosan solution. Weigh 30.0 g of sodium β-glycerophosphate powder, add it to 10 mL of deionized water, and stir magnetically at room temperature for 60 min to dissolve it evenly. Weigh 8.0 g of gelatin particles, add to 100 mL of deionized water, and mix evenly with a magnetic stirrer at 60°C for 60 min. At room temperature, the prepared chitosan solution was stirred rapidly on a magnetic stirrer, and the β-sodium glycerophosphate solution was slowly added dropwise during the stirring process, and the solution was fully stirred for 30 minutes to prepare a Cs / GP solution. Observe that there is no obvious flocculent substance in th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elastic modulus | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com