Punching method of outer tube of tubular motor and punching die for implementing punching method

A tubular motor and outer tube technology, applied in the field of metal processing, can solve the problems of low work efficiency, low processing precision, and inability to meet the requirements of accurate indexing processing of steel pipes, etc., and achieve the effect of high work efficiency and high processing precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

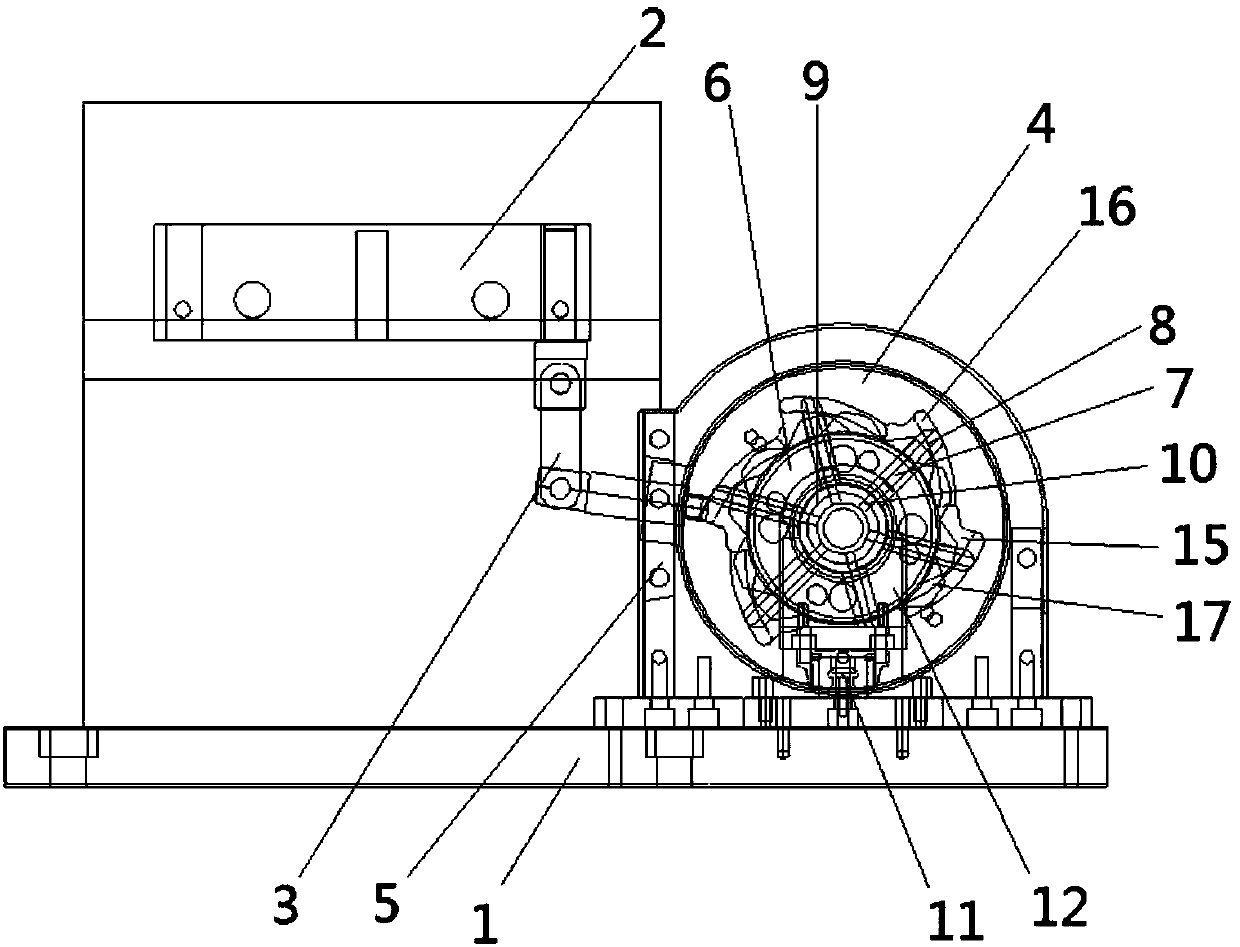

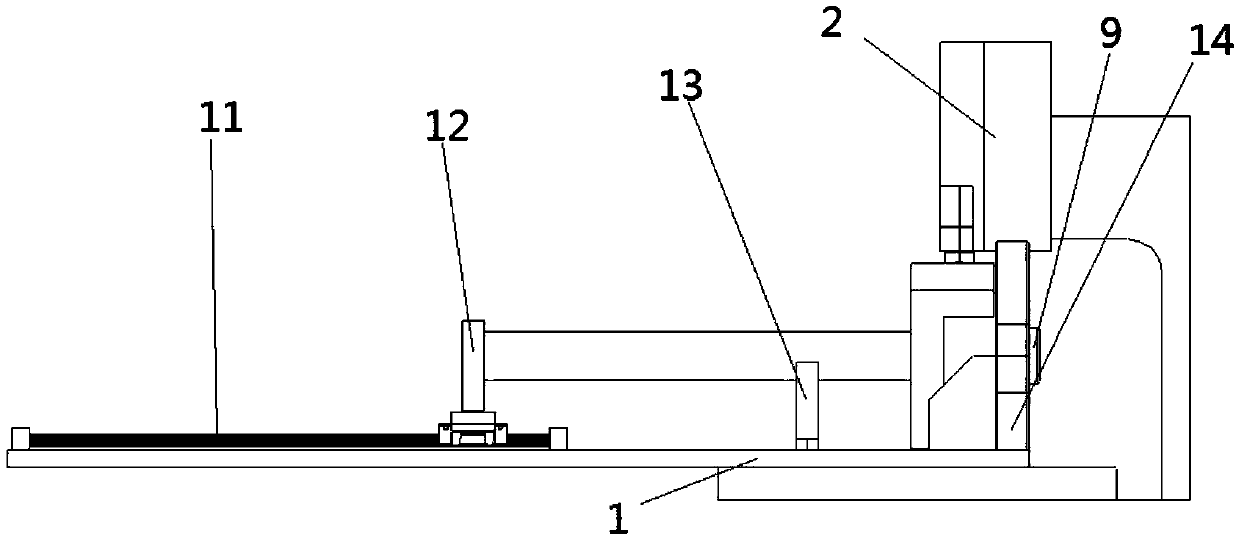

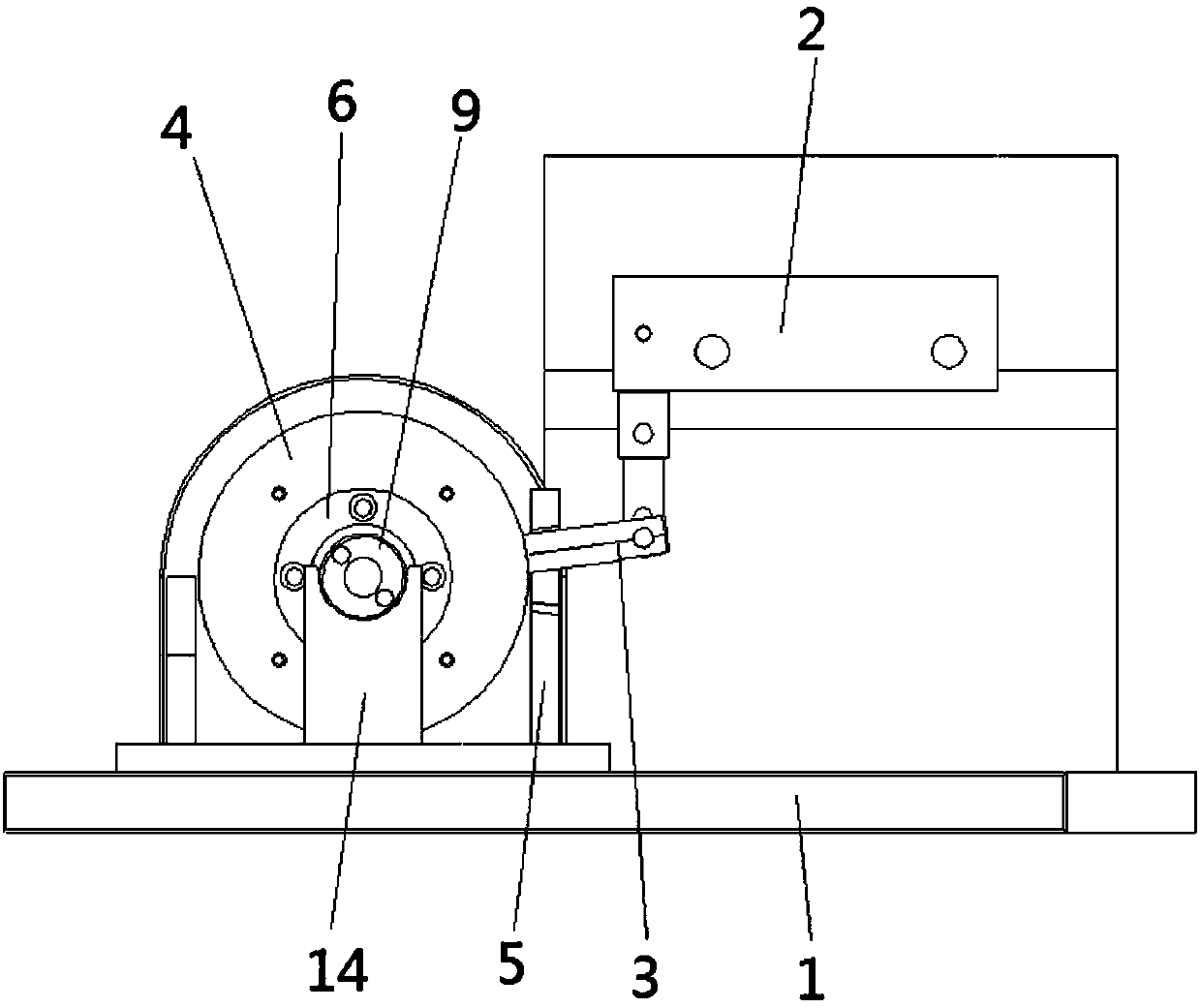

[0018] Embodiment: A method for punching holes in the outer tube of a tubular motor. The method adopts the downward movement of the press plate of the main shaft of the punching machine, so that the connecting rod drives the rotating mechanism to make a circular motion. The core is punched in the direction of the center of the circle to complete the punching of the outer tube of the tubular motor.

[0019] Each punch punches toward the center of the mold core under the action of the oblique arc-shaped track on the inner concave of the rotating mechanism.

[0020] The punching die for the outer pipe of the tubular motor that realizes the above method has a structure such as Figures 1 to 3 As shown, it includes the punch base 1, the punch base 1 is provided with the punch spindle pressure plate 2, the punch spindle pressure plate 2 is connected with the rotation mechanism 4 through the connecting rod 3, the rotation mechanism 4 can rotate around the punch spindle, and the rotat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com