Dental stereolithography-type three-dimensional printing material used for preparing dental three-dimensional formed article

A three-dimensional printing and patterning technology, applied in dental preparations, dentistry, dental prostheses, etc., can solve the problems of difficult data consistency, large polymerization shrinkage, low polymerization degree, etc., and achieve short production time, excellent deformation over time, and dimensional accuracy. excellent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

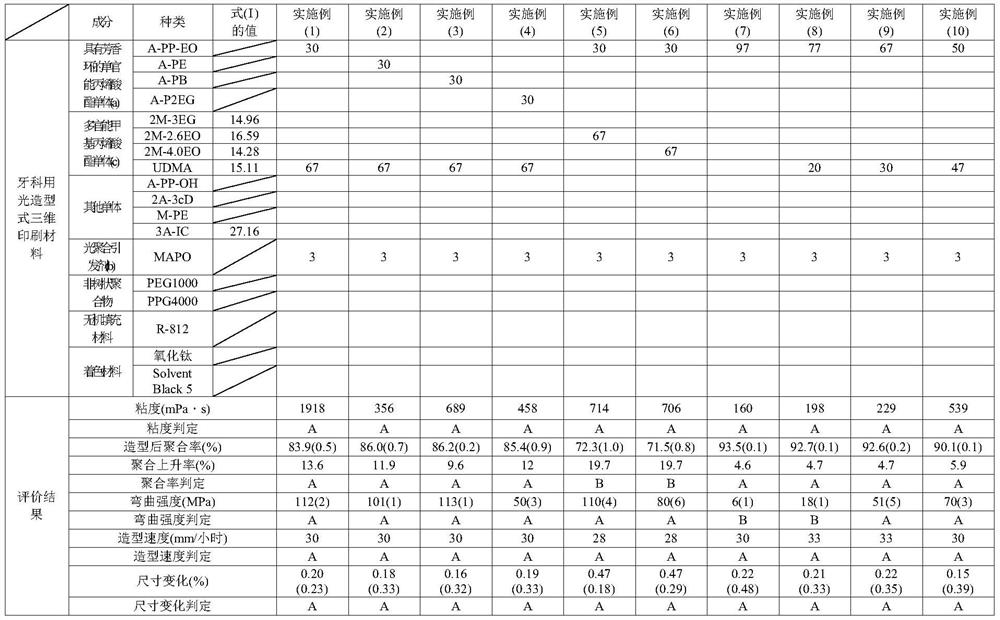

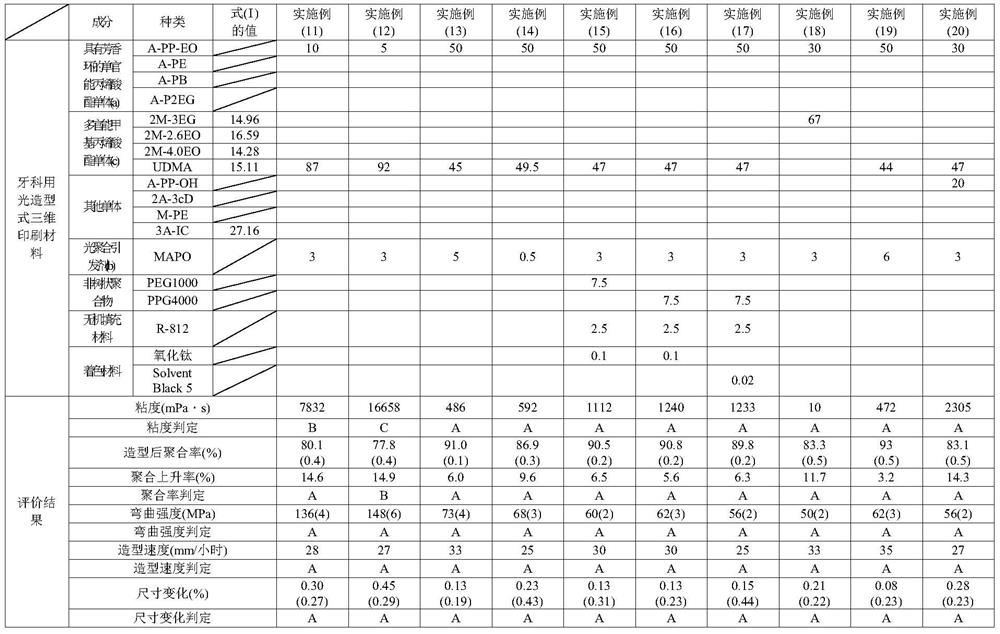

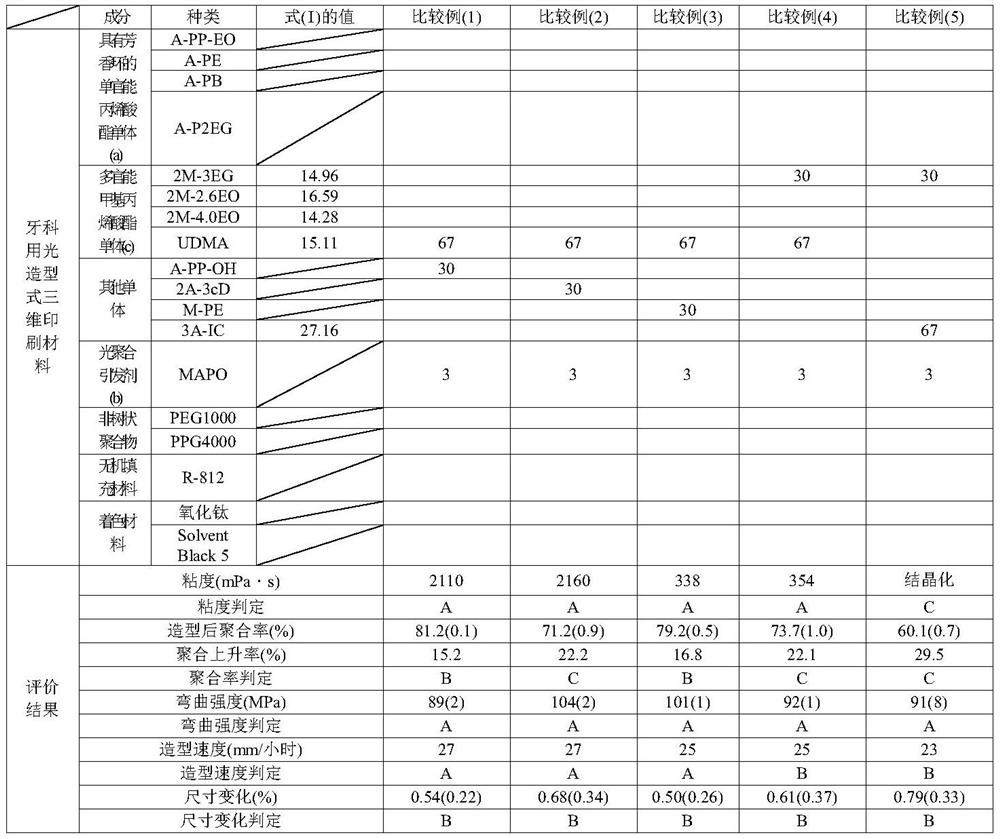

[0072] (monofunctional acrylate monomer (a) having an aromatic ring)

[0073]In the examples, as the monofunctional acrylate monomer (a) having an aromatic ring, ethoxylated o-phenylphenol acrylate (A-PP-EO), phenoxy ethyl acrylate (A-PE ), 3-phenoxybenzyl acrylate (A-PB), phenoxydiethylene glycol acrylate (A-P2EG).

[0074] (polyfunctional methacrylate monomer (c))

[0075] In Comparative Examples and Examples, as polyfunctional methacrylate monomer (c), triethylene glycol dimethacrylate (2M-3EG), ethoxylated bisphenol A dimethacrylate -EO2.6 (2M-2.6EO), Ethoxylated Bisphenol A Dimethacrylate -EO4.0 (2M-4.0EO), Urethane Dimethacrylate (UDMA).

[0076] (other monomers)

[0077] In the comparative example, as other monomers, 2-hydroxy-3-phenoxypropyl acrylate (A-PP-OH), dimethylol-tricyclodecane diacrylate (2A-3cD) were used , phenoxyethyl methacrylate (M-PE), ethoxylated isocyanurate triacrylate (3A-IC).

[0078] (photopolymerization initiator (b))

[0079] In Comparativ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com