Building template processing equipment that can be automatically adjusted and punches holes at one time

A building template and automatic adjustment technology, applied in metal processing equipment, perforation tools, manufacturing tools, etc., can solve the problems of many labor processes, large labor, inconvenient use, etc., to reduce manufacturing costs, reduce labor, work Efficiency improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

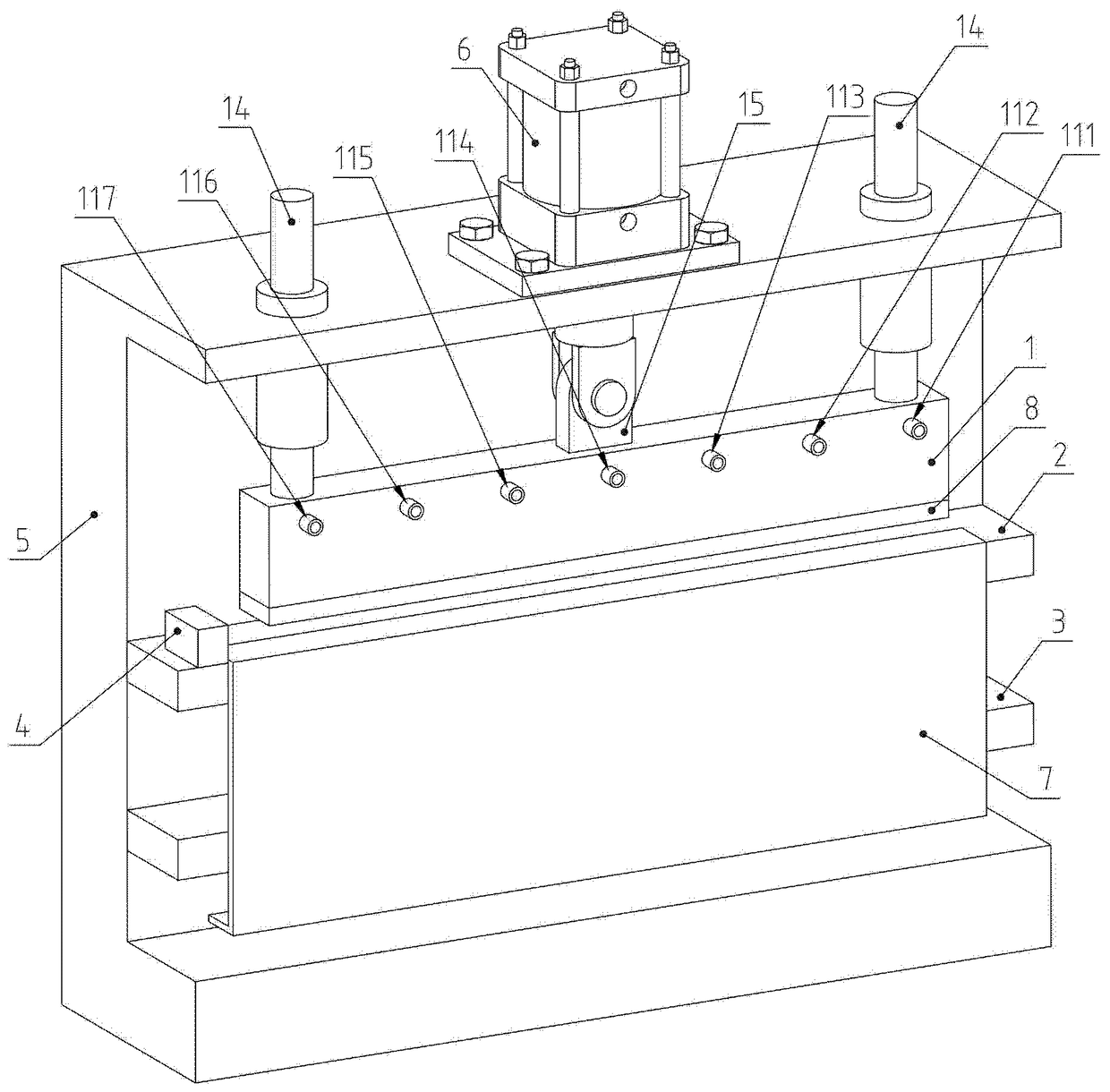

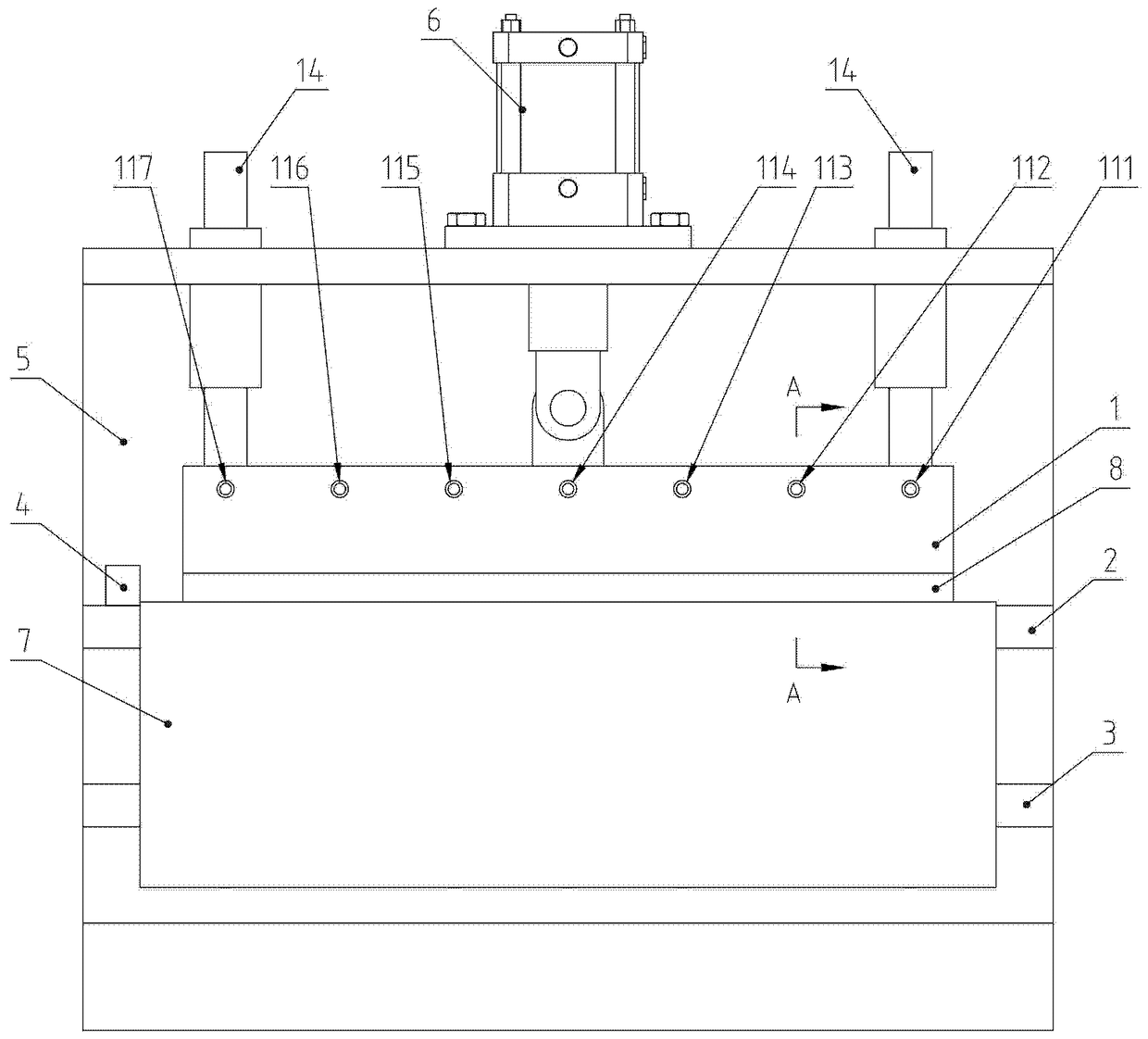

[0045] Example: see Figure 1 to Figure 11 .

[0046] A building formwork processing equipment that can be automatically adjusted and can punch holes at one time, including an upper formwork 1, a lower formwork 2, a positioning plate 3, a positioning device 4, a frame 5, a hydraulic cylinder 6, a rubber pressing plate 8, and seven piston punches Needle assembly, seven springs, seven two-position two-way solenoid valves and hydraulic oil tank 300;

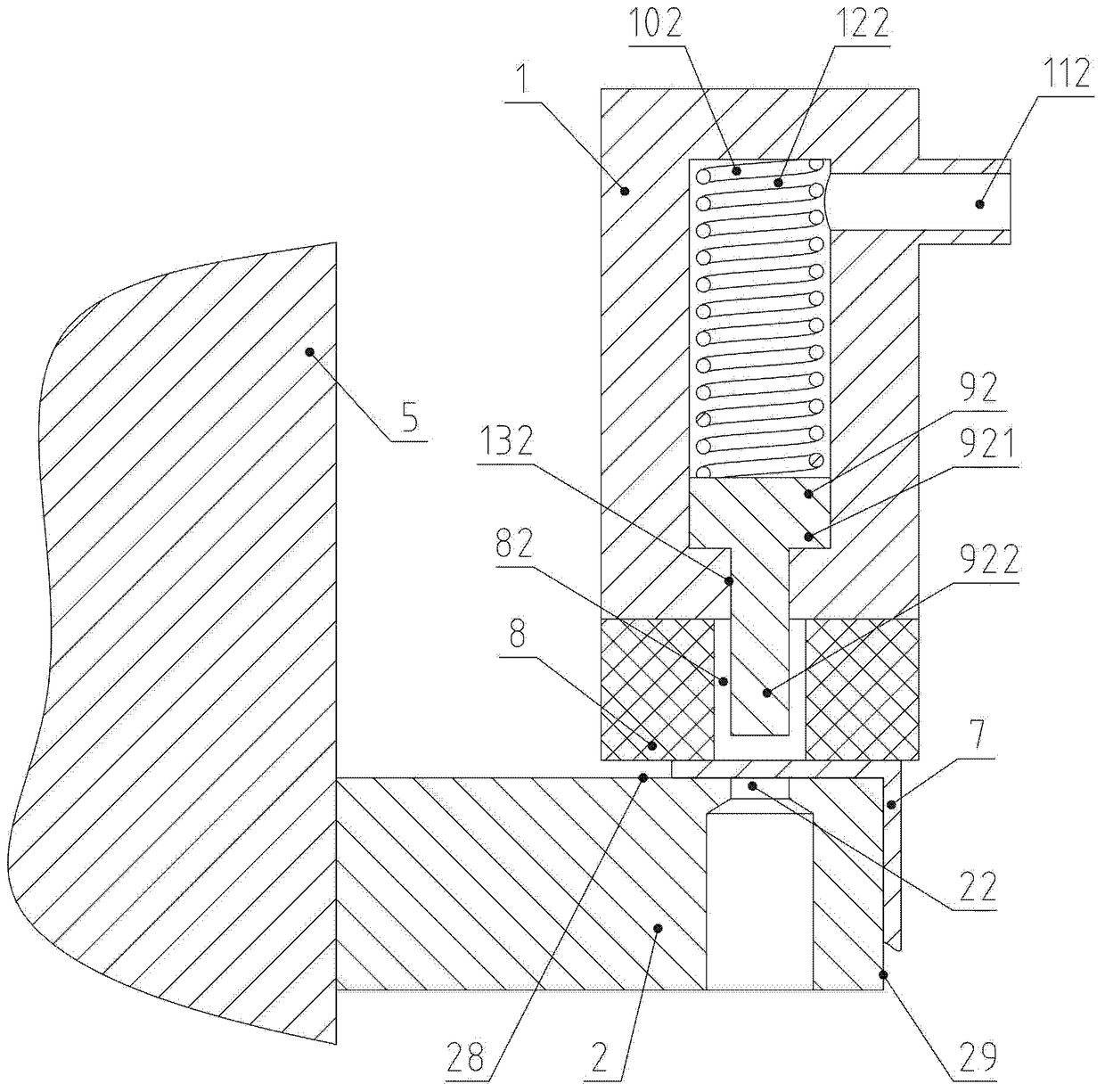

[0047] The upper part of the frame 5 is fixedly provided with two guide sleeves 51, and the cylinder body of the hydraulic cylinder 6 is fixedly connected to the upper part of the frame 5;

[0048] The upper template 1 is in the shape of a cuboid, and there are seven oil pressure chambers inside. From right to left, they are oil pressure chamber I 121, oil pressure chamber II 122, oil pressure chamber III 123, oil pressure chamber IV 124, oil pressure chamber V 125, For oil pressure chamber VI 126 and oil pressure chamber VII 127,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com